Abstract

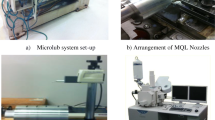

In order to achieve a more productive and environmentally friendly manufacturing of aerospace propulsion components, minimal quantity lubrication (MQL) can potentially replace the traditionally used flood cooling in different machining operations. These components are manufactured of difficult to machine alloys, which show great hardness even at elevated temperatures. Waspaloy is one of the more demanding super alloys to machine and serve as reference material in this investigation. In this paper, a turning operation is used to investigate the influence of MQL parameters such as oil type together with cutting data on cutting forces and tool wear. As a reference flood and air cooling was used. Two different type of oils were investigated, ester vs. fatty alcohol. The aerosol was directed towards the tool by two different nozzles. Responses that were measured include particle size, aerosol generation capability, cutting forces and tool wear. The experiments were conducted as a D-optimal design of experiments and evaluated by a regression analysis. No evidence of any lubrication effect can be seen. The most plausible explanation of the effects seen is the effects of cooling and heat transfer.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

7 References

Autret R., Liang S. Y., 2003, Minimum quantity lubrication in finish hard turning, http://hardingeus.com/usr/pdf/hardturn/LIANG3.PDF

Attanasio A. et al, 2006, Minimal quantity lubrication in turning: Effect on tool wear, Tribology in Manufacturing Processes, vol. 260, n3 p. 333–338.

Rahman M. et al.,2002, Experimental evaluation on the effect of minimal quantities of lubricant in milling, International Journal of Machine Tools and Manufacture, v 43, n11 p 1093–1106.

Klocke F., Eisenblätter G., 1997, Dry Cutting, Annals of the CIRP, 46/2:519–526.

MODDE version 8, 2006, User guide and tutorial, Unimetrics Inc. Kinnelon NJ, USA.

Dahlman P., Kaminski J., 1999, Aspects on High-Pressure Jet-Assisted Turning, Proceedings of the 10 th American Water Jet Conference.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2007 Springer-Verlag London Limited

About this paper

Cite this paper

Beno, T., Isaksson, M., Pejryd, L. (2007). Investigation of Minimal Quantity Lubrication in Turning of Waspaloy. In: Takata, S., Umeda, Y. (eds) Advances in Life Cycle Engineering for Sustainable Manufacturing Businesses. Springer, London. https://doi.org/10.1007/978-1-84628-935-4_53

Download citation

DOI: https://doi.org/10.1007/978-1-84628-935-4_53

Publisher Name: Springer, London

Print ISBN: 978-1-84628-934-7

Online ISBN: 978-1-84628-935-4

eBook Packages: EngineeringEngineering (R0)