Abstract

Ceramic production processes are characterized by providing quantities of the same finished goods that differ in qualities, tones and gages. This aspect becomes a problem for ceramic supply chains (SCs) that should promise and serve customer orders with homogeneous quantities of the same finished good. In this paper a mathematical programming model for the centralized master planning of ceramic SCs is proposed. Inputs to the master plan include demand forecasts in terms of customer order classes based on their order size and splitting percentages of a lot into homogeneous sub-lots. Then, the master plan defines the size and loading of lots to production lines and their distribution with the aim of maximizing the number of customer orders fulfilled with homogeneous quantities in the most efficient manner for the SC.

This research has been carried out in the framework of the project funded by the Spanish Ministry of Economy and Competitiveness (Ref. DPI2011-23597) and the Polytechnic University of Valencia (Ref. PAID-06-11/1840) entitled “Methods and models for operations planning and order management in supply chains characterized by uncertainty in production due to the lack of product uniformity” (PLANGES-FHP).

Similar content being viewed by others

Keywords

- Master planning

- Ceramic supply chains

- Mathematical programming model

- Lack of homogeneity in the product

1 Introduction

Lack of Homogeneity in the Product (LHP) appears in those productive processes which include raw materials that directly originate from nature and/or production processes with operations which confer heterogeneity to the characteristics of the outputs obtained, even when the inputs used are homogeneous (Alarcón et al. 2011). LHP in ceramic supply chains (SCs) implies the existence of units of the same finished good (FG) in the same lot that differ in the aspect (quality), tone and gage that should not be mixed to serve the same customer order. This is due to the fact that units of the same FG (e.g. ceramic tiles) should be jointly presented being necessary their homogeneous appearance. The order promising process plays a crucial role in customer requirements satisfaction and, therefore, in properly managing the special LHP characteristics. But in turn, one of the main inputs to this process is the master plan. Then, the objective of this paper is to define a master plan that anticipate LHP features and can provide the order promising process with reliable information about future homogeneous quantities available.

The paper is structured as follows. Section 22.2 describes the problem under consideration. Section 22.3 presents the mixed integer linear programming model proposed for the centralized master planning of ceramic SCs that explicitly takes into account LHP. Finally, Sect. 22.4 reports the methodology followed for the model validation and the conclusions derived from the obtained results.

2 Problem Description

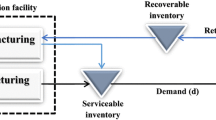

In this paper, we consider the master planning problem for replenishment, production, and distribution in ceramic tiles SCs with LHP. These SCs are assumed to be multi-item, multi-supplier, multi-facility, multi-type and multi-level distribution centers. The characteristics of the problem under study are the same as in Alemany et al. (2010) but with relevant differences introduced by the LHP consideration. As in Alemany et al. (2010) the master plan considers the capacitated lot-sizing and loading problem (Özdamar and Birbil 1998) to reflect the fact that production lots of the same product processed in different production lines present a high probability of not being homogeneous. Furthermore, the splitting of each lot into homogeneous sub-lots of the same FG is also incorporated to reflect the LHP characteristics. The sizing of lots is made in such a way that an integer number of customer order classes can be served from homogeneous quantities of each sub-lot. To this end, different customer order classes are defined according to their size. The next section describes the mixed integer programming model proposed to solve this problem.

3 Mathematical Programming Model for Ceramic Supply Chains with LHP: MP-CSC-LHP

The following mixed integer linear programming model (MP-CSC-LHP) is proposed to solve the master planning problem described above. The model MP-RDSINC proposed by Alemany et al. (2010) is considered as the starting point to formulate the present model but properly modified in order to reflect the LHP characteristics. Tables 22.1, 22.2, 22.3, 22.4, respectively, describe the indices, sets of indices, model parameters and decision variables of the MP-CSC-LHP, respectively. Those model elements that differ from the MP-RDSINC are written in italics.

Objective Function:

Constraints:

For being concise, in this section only the MP-CSC-LHP functions that differ from the MP-RDSINC are described. For more details, the reader is referred to Alemany et al. (2010). The objective function (22.1) expresses the gross margin maximization over the time periods that have been computed by subtracting total costs from total revenues. In this model, selling prices and other costs including the backlog costs can be defined for each customer class allowing reflect their relative priority.

Constraints (22.1) to (22.14) coincide with those of the MP-RDSINC and make reference to suppliers and productive limitations related to capacity and setup. Constraints (22.15–22.17) reflect the splitting of a specific lot into three homogeneous sub-lots of first quality (β1ilp + β2ilp + β3ilp = 1). The number of sub-lots considered in each lot can be easily adapted to other number different from three. Through these constraints the sizing of lots is decided based on the number of orders from different customer order classes that can be served from each homogeneous sub-lot. Customer order classes are defined based on the customer order size (i.e., the m2 ordered). Constraint (22.18) calculates for each time period, customer class and finished good the total number of orders of a specific customer class that can be served from a certain lot by summing up the corresponding number of orders served by each homogeneous sub-lot of this lot. Constraint (22.19) derives the number of each customer order class that is possible to serve from the planned production of a specific plant. Through constraints (22.15–22.19), the production is adjusted not to the aggregate demand forecast as traditionally, but to different customer orders classes.

Furthermore, in contrast to the MP-RDSINC, the distributed, stocked and sold quantities downstream the production plants are expressed in terms of the customer class whose demand will be satisfied through them being possible to discriminate the importance of each order class. Constraint (22.20) calculates the quantity of each FG to be transported from each production plant to each warehouse for each customer class based on the order number of each customer class that is satisfied by each production plant and the mean order size. Constraint (22.21) represents the inventory balance equation at warehouses for each finished good, customer class and time period. As backorders are permitted in both central warehouses and shops, sales may not coincide with the demand for a given time period. Backorder quantities in warehouses for each customer class are calculated using constraint (22.22). Constraint (22.23) limits these backorder quantities per customer class in each period in terms of a percentage of the demand of each time period. Constraint (22.24) forces to maintain a total inventory quantity higher or equal to the safety stock in warehouses. Constraint (22.25) is the limitation in the warehouses’ capacity that is assumed to be shared by all the FG and customer order classes.

Constraint (22.26) represents the inflows and outflows of FGs and customer order classes through each logistic centre. Because it is not possible to maintain inventory in shops, constraint (22.27) ensures that the total input quantity of a FG for a specific customer class from warehouses to shops coincides with the quantity sold in shops. As backorders are permitted in both central warehouses and shops, sales may not coincide with the demand for a given time period. Constraints (22.28) and (22.29) are similar to constraints (22.22) and (22.23), respectively, but referred to shops instead of warehouses. The model also contemplates non-negativity constraints and the definition of variables (22.30).

4 Model Validation and Conclusions

The MP-CSC-LHP model has been implemented in MPL (V4.11) and solved with CPLEX 6.6.0. With the aim of comparing the performance of the model with and without LHP modelling, the input data for validation has been mainly extracted for the paper of Alemany et al. (2010) that do not consider LHP: MP-RDSINC. However, some additional parameters have been necessary for the LHP version (MP-CSC-LHP). These parameters have been defined maintaining the coherence of the data used by the two models. With this input data the MP-CSC-LHP and the MP-RDSINC have been solved. Results show that MP-RDSINC obtains a greater gross margin than the MP-CSC-LHP mainly due to the lower production costs of the former. This is due to the fact that the MP-RDSINC should produce a lower quantity than the MP-CSC-LHP for satisfying the aggregate demand (Table 22.5).

This result can lead to the wrong conclusion that the MP-RDSINC outperforms the MP-CSC-LHP. This is not true because, the MP-RDSINC does not take into account the homogeneity requirement for customer orders and considers the demand forecasts in an aggregate manner. To obtain results from both models that were really comparable, the lots obtained by the MP-RDSINC model solution (value of decision variable MPilpt) was transferred as an input data to the MP-CSC-LHP computing the new gross margin obtained (MP-RDSINC-LHP). As expected, the new value of the gross margin for the MP-RDSINC-LHP was lower than the MP-CSC-LHP because a lower number of customer orders were able to be served with homogeneous quantities by the lots initially defined by the MP- RDSINC (see backorder costs for MP-RDSINC-FHP-mod).

References

Alarcón F, Alemany MME, Lario FC, Oltra RF (2011) La falta de homogeneidad del producto (FHP) en las empresas cerámicas y su impacto en la reasignación de inventario. Boletín de la Sociedad Española de Cerámica y Vidrio 50(1):49–58

Alemany MME, Boj JJ, Mula J, Lario FC (2010) Mathematical programming model for centralised master planning in ceramic tile supply chains. Int J Prod Res 48(17):5053–5074

Özdamar L, Birbil SI (1998) Hybrid heuristics for the capacitated lot sizing and loading problem with setup times and overtime decisions. Eur J Oper Res 110:525–547

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag London

About this paper

Cite this paper

Mundi, M.I., Alemany Díaz, M.M.E., Boza, A., Poler, R. (2014). Managing Qualities, Tones and Gages of Ceramic Supply Chains Through Master Planning. In: Prado-Prado, J., García-Arca, J. (eds) Annals of Industrial Engineering 2012. Springer, London. https://doi.org/10.1007/978-1-4471-5349-8_22

Download citation

DOI: https://doi.org/10.1007/978-1-4471-5349-8_22

Published:

Publisher Name: Springer, London

Print ISBN: 978-1-4471-5348-1

Online ISBN: 978-1-4471-5349-8

eBook Packages: EngineeringEngineering (R0)