Abstract

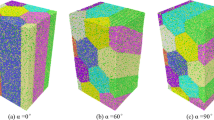

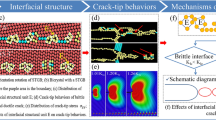

The behaviour of microstructurally small cracks is heavily dependent upon the microstructural features in its immediate surroundings such as grain boundaries, crystallographic orientations, phases, etc. Crystallographic orientations of grains is one such feature and it’s influence on the crack tip opening displacements (CTOD) of a small crack is investigated in presented work. The principal objective is to ascertain the difference in influence of crystallographic orientations between 2D lattice rotations (2D models) and full 3D lattice rotations (3D models). A finite-element based model that accounts for randomly shaped and sized grains is used. A small, inclined surface crack is introduced in a selected surface grain. Since a Stage I crack is assumed, the crack is always placed in a slip plane. Models are then loaded monotonically in uniaxial tension up to a maximum load of 1.12 yield stress. The influence that a random grain structure imposes on a Stage I crack is then assessed by calculating the CTOD values for single crystal and polycrystal models. It is shown that crystallographic orientations significantly impact the crack tip displacements for both 2D and 3D models. In some cases this effect is more pronounced for the 3D models.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

K. J. Miller. The behaviour of short fatigue cracks and their initiation. Part II-A general summary. Fatigue & Fracture of Engineering Materials & Structures, 10(2):93–113, 1987.

K. Hussain. Short fatigue crack behaviour and analytical models: a review. Engineering Fracture Mechanics, 58(4):327–354, November 1997.

K. Hussain, E. R. de los Rios, and A. Navarro. A two-stage micromechanics model for short fatigue cracks. Engineering Fracture Mechanics, 44(3):425–436, February 1993.

W. L. Morris, O. Buck, and H. L. Marcus. Fatigue crack initiation and early propagation in Al 2219-T851. Metallurgical Transactions A, 7A:1161–1165, August 1976.

Y. H. Zhang and L. Edwards. On the blocking effect of grain boundaries on small crystallographic fatigue crack growth. Materials Science and Engineering A, 188(1–2):121–132, November 1994.

O. Dber, B. Knkler, U. Krupp, H.-J. Christ, and C.-P. Fritzen. Experimental characterization and two-dimensional simulation of short-crack propagation in an austenitic-ferritic duplex steel. International Journal of Fatigue, 28(9):983–992, September 2006.

S. Suresh. Fatigue of materials. Cambridge University Press, Cambridge, 1991.

V. Tvergaard, Y. Wei, and J. W. Hutchinson. Edge cracks in plastically deforming surface grains. European Journal of Mechanics — A/Solids, 20(5):731–738, September–October 2001.

T. Zhai, A. J. Wilkinson, and J. W. Martin. A crystallographic mechanism for fatigue crack propagation through grain boundaries. Acta Materialia, 48(20):4917–4927, December 2000.

H. Riesch-Oppermann. VorTess generation of 2-D random Poisson—Voronoi mosaics as framework for micromechanical modeling of polycrystalline materials-algorithm and subroutines description. Technical Report FZKA 6325, Forschungszentrum Karlsruhe, 1999.

S. Weyer, A. Frohlich, H. Riesch-Oppermann, L. Cizelj, and M. Kovač. Automatic finite element meshing of planar voronoi tessellations. Engineering Fracture Mechanics, 69(8):945–958, May 2002.

I. Simonovski. Mechanisms for thermal fatigue initiation and crack propagation in NPP components. 2nd mid term report. Technical Report, Jožef Stefan Institute, DG-JRC, Institute for Energy (accessible through www.rcp.ijs.si/isimonovski/Papers/Simonovski2005 2.pdf), 2005.

G. P. Potirniche and S. R. Daniewicz. Analysis of crack tip plasticity for microstructurally small cracks using crystal plasticity theory. Engineering Fracture Mechanics, 70(13):1623–1643, September 2003.

V. P. Bennett and D. L. McDowell. Crack tip displacements of microstructurally small surface cracks in single phase ductile polycrystals. Engineering Fracture Mechanics, 70(2):185–207, January 2003.

R. Hill and J. R. Rice. Constitutive analysis of elastic-plastic crystals at arbitrary strain. Journal of the Mechanics and Physics of Solids, 20(6):401–413, 1972.

J. R. Rice. On the structure of stress-strain relations of time-dependent plastic deformation in metals. Journal of Applied Mechanics, 37:728–737, 1970.

A. Needleman. Computational mechanics at the mesoscale. Acta Materialia, 48(1):105–124, January 2000.

D. Peirce, R. J. Asaro, and A. Needleman. Material rate dependence and localized deformation in crystalline solids. Acta Metallurgica, 31(12):1951–1976, December 1983.

Yonggang Huang. A user-material subroutine incorporating single crystal plasticity in the ABAQUS finite element program. Technical Report, Division of Applied Sciences, Harvard University (accessible through www.columbia.edu/~jk2079/fem/umat_documentation.pdf), 1991.

I. Simonovski, K.-F. Nilsson, and L. Cizelj. Material properties calibration for 316L steel using polycrystalline model. In 13th International Conference on Nuclear Engineering, May 16–20, 2005, Beijing, China, May 2005.

S. Weyer. Experimentelle Untersuchung und Mikromechanische Modellierung des Schdigungsverhaltens von Aluminiumoxid unter Druckbeanspruchung. Ph.D. thesis, Universitt Karlsruhe, 2001.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2009 Springer Science+Business Media B.V

About this paper

Cite this paper

Simonovski, I., Cizelj, L. (2009). Small Crack in a Simulated Columnar Polycrystalline Aggregate with Random 2D and 3D Lattice Orientations. In: Pantelakis, S., Rodopoulos, C. (eds) Engineering Against Fracture. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-9402-6_19

Download citation

DOI: https://doi.org/10.1007/978-1-4020-9402-6_19

Publisher Name: Springer, Dordrecht

Print ISBN: 978-1-4020-9401-9

Online ISBN: 978-1-4020-9402-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)