Abstract

The HCF response to burnishing of a number of structural materials is compared and contrasted. It is shown that alloys which exhibit marked work-hardening during burnishing respond very beneficially with regard to HCF performance while others which show little work-hardening may even react with losses in HCF strength. Possible explanations for such behavior are outlined in terms of mean stress and environmental sensitivities of the fatigue strengths of the various materials and microstructures.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Schulze V. (2006), Modern Mechanical Surface Treatment, Wiley-VCH.

Wohlfahrt H. (1984), The Influence of Peening Conditions on The Resulting Distributions of Residual Stress, Shot Peening (H. O. Fuchs, ed.) American Shot Peening Society, 316.

Wohlfahrt H. (1987), Practical Aspects of the Application of Shot Peening to Improve the Fatigue Behaviour of Metals and Structural Components, Shot Peening (H. Wohlfahrt, R. Kopp and O. Vöhringer, eds.), DGM, Oberursel, Germany, 563.

Altenberger I. (2002), Alternative Mechanical Surface Treatments: Microstructures, Residual Stresses & Fatigue Behaviour, Shot Peening (L. Wagner, ed.) Wiley-VCH, ICSP8, Garmisch-Partenkirchen, 421.

Mhaede M. H., Wollmann M. and Wagner L. (2008), Influence of Ball-Burnishing on Stress Corrosion Cracking and Corrosion, Fatigue and Corrosion Fatigue of Al 2024 and Al 6082, ICSP10, Tokyo, 505.

Wagner L. and Wollmann M. (2008), Shot Peening of Non-Ferrous Alloys to Enhance Fatigue Performance, ICSP10, Tokyo, 355.

Burck C. H., Sullivan C. P. and Wells C. H. (1970), Fatigue of a Glass Bead Blasted Nickel-Base Superalloy, Met. Trans. 1A, 1595.

Leverant G. R., Langer S., Yuen A. and Hopkins, S. W. (1979), Surface residual stresses, surface topography and the fatigue behavior of Ti-6AI-4V, Met. Trans. 10A, 251.

Wagner L. and Lütjering G. (1982), Influence of Shot Peening on the Fatigue Behavior of Ti-Alloys, Shot Peening, Pergamon Press, 453.

Hack J. E. and Leverant G. R. (1982), Influence of Compressive Residual Stress on the Crack-Opening Behavior of Part-Through Fatigue Cracks, Residual Stress Effects in Fatigue, ASTM STP 776, 204.

Muto Y., Fair G. H., Noble B. and Waterhouse R. B. (1987), The Effect of Residual Stresses Induced by Shot Peening on Fatigue Crack Propagation in Two High Strength Aluminum Alloys, Fat. and Fract. of Eng. Mat. and Struct. 10, 261.

Nisitani H. and Fujimura K. (1997), Initiation and Growth Behaviour of a Fatigue Crack in Shot-Peened Steel, Computer Methods and Experimental Methods for Surface Treatment Effects 3, Oxford, Computational Mechanics Publications, (ROYAUME-UNI ed.), 13.

Wagner L. and Müller C. (1992), Effect of Shot Peening on Fatigue Behavior in Al-Alloys, J. Materials Manufacturing & Processing, 423.

Dörr T. and Wagner L. (1996), Fatigue Behavior of Shot Peened TIMETAL 1100: Effects of Microstructure and Stress Gradient, Surface Performance of Titanium Alloys (J. K. Gregory, H. J. Rack and D. Eylon, eds.) TMS AIME, 231.

Kocan M., Rack H. J. and Wagner L. (2005), Fatigue Performance of Metastable Beta Titanium Alloys: Effects of Microstructure and Surface Finish, Beta Titanium Alloys of the 00's (R. R. Boyer, R. F. Denkenberger, J. Fanning and H. J. Rack, eds.), JMEPEG 14, 765.

Schwarz T. and Kockelmann H. (1992), VDI Report 940, 99.

Gerdes C. and Lütjering G. (1984), Influence of Shot Peening on Notched Fatigue Strength of Ti-6Al-4V, Shot Peening (H. O. Fuchs, ed.) American Shot Peening Society, 175.

Gregory J. K., Müller C. and Wagner L. (1993), Bevorzugte Randschichtaushärtung: Neue Verfahren zur Verbesserung des Dauerschwingverhaltens mechanisch belasteter Bauteile, Metall 47, 915.

Rodopoulos C. A., Edwards R. E., Curtis S., Romero J. S., Choi J.-H., de los Rios E. and Levers A. (2002), Theoretical Analysis of Beneficial and Detrimental Effects of Controlled Shot Peening in High Strength Aluminium Alloys, Shot Peening (L. Wagner, ed.) Wiley-VCH, ICSP8, Garmisch-Partenkirchen, Germany, 547.

Zheng Y. (2002), Finite Element Simulation of Shot Peen Forming, Shot Peening (L. Wagner, ed.) Wiley-VCH, ICSP8, Garmisch-Partenkirchen, Germany, 554.

Holzwarth U., Kiese J. and Wagner L. (1999), Effects of Surface Finishing on Fatigue Performance of the Surgical Implant Alloy Ti-6Al-7Nb, Fatigue Behavior of Titanium Alloys, (R. R. Boyer, D. Eylon and G. Lütjering, eds.), TMS, 323.

Lindemann J. and Wagner L. (1997), Mean Stress Sensitivity in Fatigue in Alpha, (Alpha + Beta) and Beta Titanium Alloys, Materials Science and Engineering A 234–239, 1118.

Zhang J., Lindemann J. and Wagner L. (2004), Influence of Prior Deformation on the Development of Duplex Microstructures and Fatigue Strengths in Ti-6242, Ti-2003 Science and Technology (G. Lütjering and J. Albrecht, eds.) Wiley-VCH, Weinheim, 1823.

Woodfield A. P., Gorman M. D., Sutliff J. A. and Corderman R. R. (1998), Effect of Microstructure on Dwell Fatigue Behavior of Ti-6242, Fatigue Behavior of Titanium Alloys (R. R. Boyer, D. Eylon, G. Lütjering, eds.) TMS, 111.

Gunkel J. (2008), Dauerschwingverhalten des metastabilen austenitischen Stahls X5CrNi18-10 nach dem Festwalzen im glatten und gekerbten Zustand, Diploma thesis, TU Clausthal, IWW, Germany.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2009 Springer Science+Business Media B.V

About this paper

Cite this paper

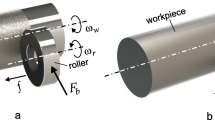

Wagner, L., Ludian, T., Wollmann, M. (2009). Ball-Burnishing and Roller-Burnishing to Improve Fatigue Performance of Structural Alloys. In: Pantelakis, S., Rodopoulos, C. (eds) Engineering Against Fracture. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-9402-6_1

Download citation

DOI: https://doi.org/10.1007/978-1-4020-9402-6_1

Publisher Name: Springer, Dordrecht

Print ISBN: 978-1-4020-9401-9

Online ISBN: 978-1-4020-9402-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)