Abstract

This chapter begins with a discussion of the two main modes of liquid droplet embryo formation in condensation: homogeneous and heterogeneous, followed by a detailed examination of dropwise and filmwise condensation with different approximations and methods.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

References

Asali, J. C., Hanratty, T. J., & Andreuss, P. (1985). Interfacial drag and film height for vertical annular flow. AIChE Journal, 31(6), 895–902.

Bejan, A. (1991). Film condensation on a upward facing plate with free edges. International Journal of Heat and Mass Transfer, 34, 578–582.

Brauer, H. (1956). Stromung und Warmeubergang bei Reiselfilmen. VDI Forschung, 22, 1–40.

Butterworth, D. (1981). Simplified methods for condensation on a vertical surface with vapor shear (UKAEA Report). AERE-R9683.

Butterworth, D. (1983). Film condensation of pure vapor. Heat exchanger handbook, chapter 2.6.2. Washington, DC: Hemisphere.

Carey, V. P. (2016). Liquid-vapor phase-change phenomena: An introduction to the thermophysics of vaporization and condensation processes in heat transfer equipment (3rd ed.). New York, NY: Taylor & Francis.

Carpenter, F. S., & Colburn, A. P. (1951). The effect of vapor velocity on condensation inside tubes, in Proceedings of General Discussion of Heat Transfer (pp. 20–26). Institute of Mechanical Engineers and American Society of Mechanical Engineers.

Chun, K. R., & Seban, R. A. (1971). Heat transfer to evaporating liquid films. Journal of Heat Transfer, 93, 391–396.

Collier, J. G., & Thome, J. R. (1994). Convection boiling and condensation (3rd ed.). Oxford: Oxford University Press.

Eucken, A. (1937). Energie- und Stoffaustausch an Grenzflächen. Naturwissenschaften, 25, 209–219.

Faghri, A. (1986). Turbulent film condensation in a tube with cocurrent and countercurrent vapor flow, in AIAA Paper No. 86-1354.

Faghri, A. (2016). Heat pipe science & technology (2nd ed.). Columbia, MO: Global Digital Press.

Faghri, A., Chen, M. M., & Morgan, M. (1989). Heat transfer characteristics in two-phase closed conventional and concentric annular thermosyphons. Journal of Heat Transfer, 111(3), 611–618.

Fujii, T. (1991). Theory of laminar film condensation. New York, NY: Springer.

Graham, C., & Griffith, P. (1973). Drop size distribution and heat transfer in dropwise condensation. International Journal of Heat and Mass Transfer, 16, 337–346.

Griffith, P. (1983). Dropwise condensation. In E. U. Schlunder (Ed.), Heat exchange design handbook, chapter 2.6.5 (Vol. 2). New York, NY: Hemisphere Publishing.

Habib, I. S., & Na, T. P. (1974). Prediction of heat transfer pipe flow with constant wall temperature. Journal of Heat Transfer, 96, 253–254.

Harley, C., & Faghri, A. (1994). Transient two-dimensional gas-loaded heat pipe analysis. Journal of Heat Transfer, 116, 716–723.

Hewitt, G. F., Bott, T. R., & Shires, G. L. (1994). Process heat transfer. Boca Raton, FL: CRC Press.

Kutateladze, S. S. (1982). Semi-empirical theory of film condensation of pure vapors. International Journal of Heat and Mass Transfer, 25, 653–660.

Labuntsov, D. A. (1957). Heat transfer in film condensation of pure steam on vertical surfaces and horizontal tubes. Teploenergetika, 4, 72–80.

Lin, L., & Faghri, A. (1998). Condensation in a rotating stepped wall heat pipe with hysteretic annular flow. Journal of Thermophysics and Heat Transfer, 12(1), 94–99.

McCormick, J. L., & Baer, E. (1963). On the mechanism of heat transfer in dropwise condensation. Journal of Colloid Science, 18, 208–216.

Mikic, B. B. (1969). On mechanism of dropwise condensation. International Journal of Heat and Mass Transfer, 12, 1311–1323.

Nusselt, W. (1916). Die Oberflächenkondensation des Wasserdampfes. Z. Vereins deutscher Ininuere, 60, 541–575.

Rohsenow, W. M. (1956). Heat transfer and temperature distribution in laminar film condensation. Transactions of the ASME, 78, 1645–1648.

Rohsenow, W. M., Webber, J. H., & Ling, T. (1956). Effect of vapor velocity on laminar and turbulent film condensation. Transactions of the ASME, 78, 1637–1643.

Seban, R. (1954). Remarks on film condensation with turbulent flow. Transactions of the ASME, 76, 299–303.

Shafrin, E. G., & Zisman, W. A. (1960). Constitutive relations in the wetting of low energy surfaces and the theory of the retraction method of preparing monolayers. Journal of Physical Chemistry, 64, 519–524.

Shekriladze, I. G., & Gomelauri, V. I. (1966). Theoretical study of laminar film condensation of flow vapour. International Journal of Heat and Mass Transfer, 9, 581–591.

Stephan, K. (1992). Heat transfer in condensation and boiling. Berlin: Springer.

Szablewski, W. (1968). Turbulent Parallelstromunjen. Zeitshr. Ang. Math Mech., 48, 35.

Author information

Authors and Affiliations

Corresponding author

Problems

Problems

-

7.1.

For a liquid–vapor phase-change problem, explain how the interface affects heat transfer. Describe the conditions under which the interfacial heat transfer resistance is not negligible.

-

7.2.

Perform an energy balance for a control volume that includes a liquid–vapor interface, and show that the conservation of mass at the liquid–vapor interface in film condensation is [see Eq. (7.80)]

$$\left[ {\rho_{\ell } \left( {u_{\ell } \frac{{{\text{d}}\delta }}{{{\text{d}}x}} - v_{\ell } } \right)} \right]_{I} = \left[ {\rho_{\text{v}} \left( {u_{\text{v}} \frac{{{\text{d}}\delta }}{{{\text{d}}x}} - v_{\text{v}} } \right)} \right]_{I} ,\quad y = \delta$$ -

7.3.

A beverage can with diameter of 65 mm and a height of 120 mm is removed from a refrigerator with a temperature of 4 °C and placed in a room at temperature of 30 °C and relative humidity of 75%. What is the condensation rate if the condensation can be assumed to be dropwise? If the relative humidity is changed to 50%, how will condensation rate change?

-

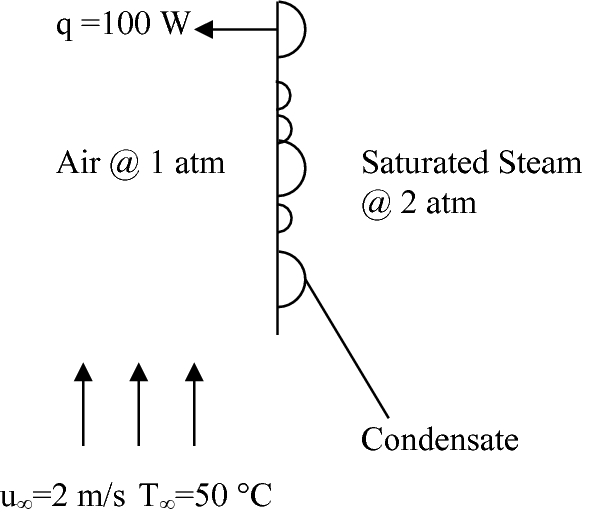

7.4.

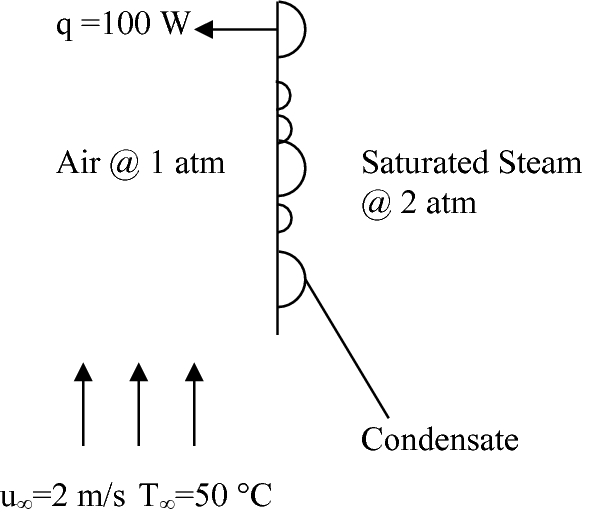

A square vertical plate 0.5 m long separates saturated steam at 2 atm from 50 °C air blowing parallel to the plate at 2 m/s (see Fig. P7.4). 100 W is transferred from the plate to the air by convective cooling. What is the condensation rate assuming dropwise condensation?

Fig. P7.4

-

7.5.

A bathroom mirror is initially at 20 °C. As a bath is drawn, the room temperature increases to 30 °C and the relative humidity increases to 90%. Calculate the heat transfer rate for a single droplet of condensate 1 mm in diameter. Discuss which thermal resistances are most significant.

-

7.6.

Consider the dropwise condensation of saturated vapor at 30 °C on a vertical plate that is maintained at 20 °C. The equilibrium contact angle of the plate is \(\theta_{\text{c}} = 90^{ \circ }\), while the receding and advancing contact angles are \(\theta_{\text{r}} = 75^{ \circ }\) and \(\theta_{\text{a}} = 105^{ \circ }\), respectively. If the maximum adhesion forces on the droplet is given as:

$$F_{\sigma } = \frac{{\sigma_{{\ell {\text{v}}}} D}}{{\frac{\pi }{{\theta_{\text{a}} - \theta_{\text{r}} }} - \frac{{\theta_{\text{a}} - \theta_{\text{r}} }}{\pi }}}\left[ {\sin (\theta_{\text{a}} - \theta_{\text{r}} ) + \cos (\theta_{\text{a}} - \theta_{\text{r}} ) + 1} \right]$$where D is the droplet diameter.

-

(a)

Calculate the maximum stable diameter of a droplet attached to the surface of the plate (ignore droplet deformation and assume that the volume of the droplets is \(V_{\text{d}} = \left( {2/3} \right)\pi \left( {D/2} \right)^{3}\), \(\rho_{\ell } = 1000\,{\text{kg}}/{\text{m}}^{3}\), g = 9.81 m/s2, and \(\sigma_{{\ell {\text{v}}}} = 0.0725\,{\text{N}}/{\text{m}}\)).

-

(b)

Droplet distribution function, \(n^{\prime \prime} (D)\), represents the number of droplets of that diameter D per unit area at any given time. If the droplet distribution function, \(n^{\prime \prime} (D)\), is given as

$$n^{\prime \prime} (D) = \frac{2}{{3\pi D_{ \text{max} } }}D^{ - 1} \quad (\# / {\text{unit}}\,{\text{area)}}$$Find the fraction of the surface covered by liquid droplets (ignore droplet deformation and assume that the interfacial area between a droplet and the plate is \(A_{\text{d}} = \pi \left( {D/2} \right)^{2}\)). The minimum sustainable droplet diameter is \(D_{ \text{min} } = 4\sigma_{{\ell {\text{v}}}} v_{\ell } T_{\text{v}} /\left[ {h_{{\ell {\text{v}}}} \left( {T_{\text{v}} - T_{\text{w}} } \right)} \right]\) with \(v_{\ell } = 1.003 \times 10^{ - 3} \,{\text{m}}^{3} /{\text{kg}}\) and \(h_{{\ell {\text{v}}}} = 2429.77\,{\text{kJ}}/{\text{kg}}\).

-

c)

If the convective heat transfer coefficient between the flat plate and gas is given as h = 25 W/m2 K, calculate the rate of heat transfer through the vapor phase per unit area of the flat plate.

-

(a)

-

7.7.

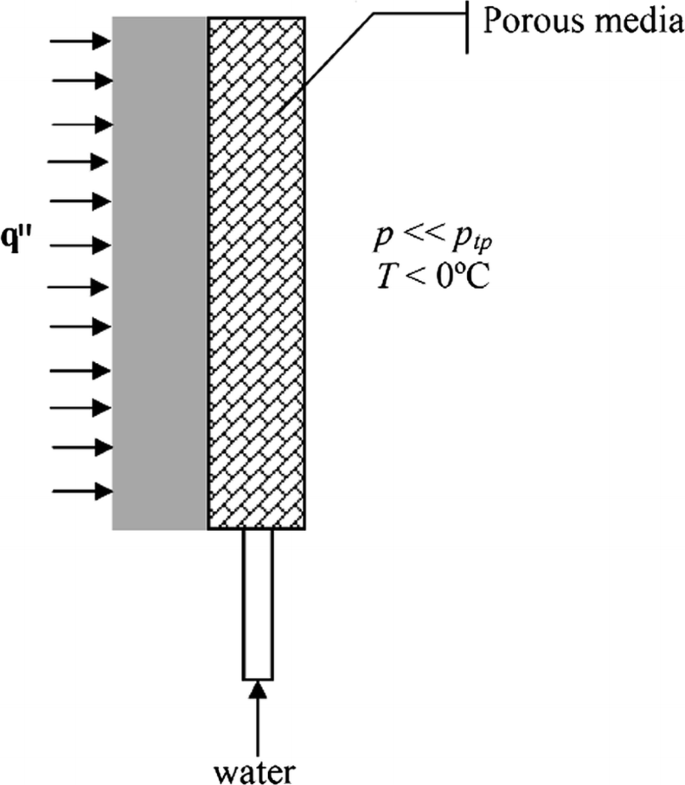

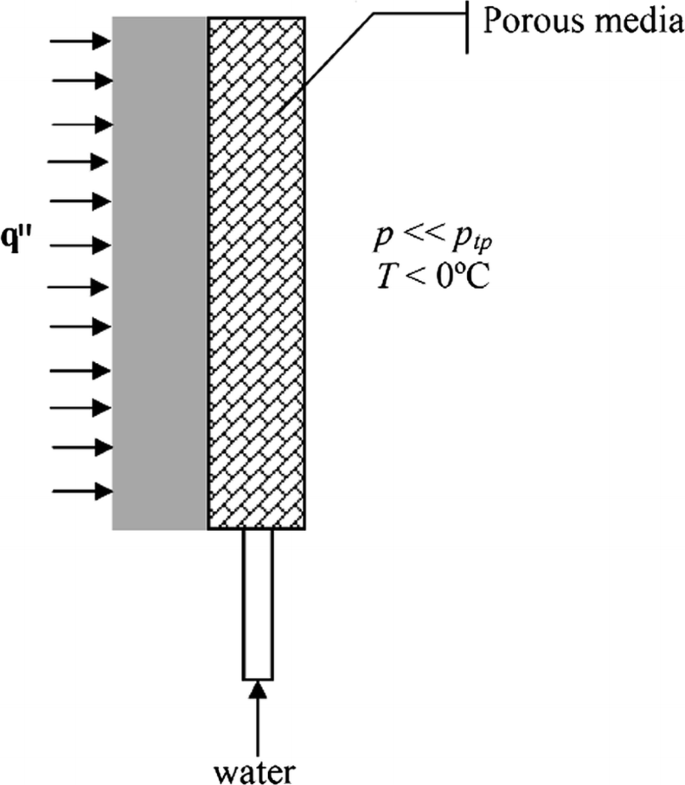

In very low pressure environments, sensible cooling is typically not sufficient due to very low conductivity of the gas. To be able to reject high rates of heat, a cooling scheme as shown in Fig. P7.7 is proposed. The porous media is connected to a liquid reservoir on the bottom. One side of the surface is open to environment, and the other side is connected to the heat source. Explain how this system works, and outline the heat transfer mechanism.

Fig. P7.7

-

7.8.

Many assumptions are made in Nusselt analysis. Discuss the reasonability of these assumptions and their expected effects on heat transfer.

-

7.9.

For film condensation of steam at atmospheric pressure, find the distance from the top of a vertical plate at which a laminar flow would become wavy. What is the average heat transfer coefficient for this plate? The heat removal rate can be assumed to be 500 kW/m2.

-

7.10.

Assuming that the plate in the previous problem has a length of 5 cm and recognizing that this exceeds the maximum laminar length found in the previous problem, find the average heat transfer coefficient for the plate by using both the Kutateladze correlation (which assumes that wavy flow exists along the length at some point) and the classical Nusselt analysis. Compare the two answers.

-

7.11.

For a vertical pipe at 25 °C with a length of 2 m in a saturated steam environment of 100 °C, find the average heat transfer coefficient of an external turbulent film condensation. What is the corresponding mass flow rate?

-

7.12.

Assume that an interfacial shear stress of 0.5 N/m2 exists in the film condensation on a vertical plate with the physical properties of Problem 7.7. Find the corresponding average heat transfer coefficient for this configuration. The imposed pressure gradient that drives the flow is 2000 N/m3.

-

7.13.

The effect of vapor flow on film condensation was considered in Sect. 7.3.4 by introducing a pressure gradient imposed by the motion of the adjacent vapor and a shear stress at the interface. A more rigorous analysis requires consideration of the vapor flow using boundary-layer theory. Write the complete governing equations for both liquid and vapor flows, and give the corresponding boundary conditions.

-

7.14.

A pure vapor at its saturation temperature, Tsat, flows downward across a horizontal cylindrical tube with a wall temperature of Tw (Tw < Tsat). The downward vapor velocity is \(u_{\infty }\). Write the governing equations and corresponding boundary conditions for the convective condensation problem. The pressure gradient in the vapor flow can be determined by assuming potential vapor flow.

-

7.15.

When a stagnant pure vapor condenses on the outer surface of a horizontal cylinder, the condensate generated from the top of the cylinder flows along its surface and eventually drips from the bottom of the cylinder. The driving force of the liquid condensate flow is the tangential component of the gravitational force along the surface of the cylinder. Perform Nusselt analysis to get the average heat transfer coefficient, and compare your result with Eq. (7.196).

-

7.16.

Condensation on the outer surface of a vertical cylinder is often estimated using a correlation for condensation on a vertical plate. This treatment is valid only if the thickness of the liquid film is much smaller than the radius of the vertical cylinder. For condensation over a thin vertical cylinder, the effect of curvature of the cylindrical surface on the condensation must be considered. This requires that the governing equations be written in the cylindrical coordinate system. Obtain the film thickness for film condensation on the outer surface of a cylinder using Nusselt’s theory.

-

7.17.

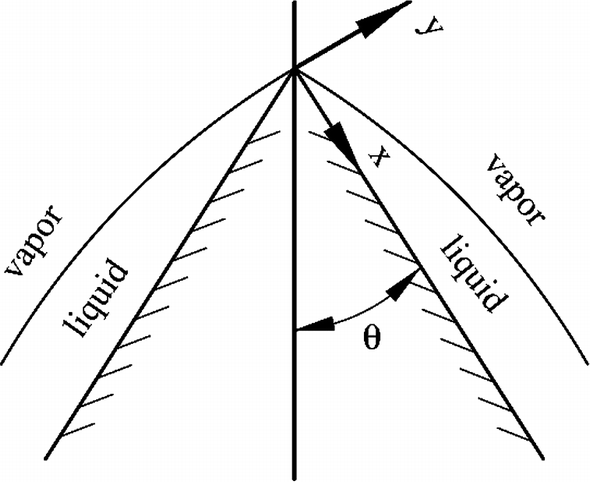

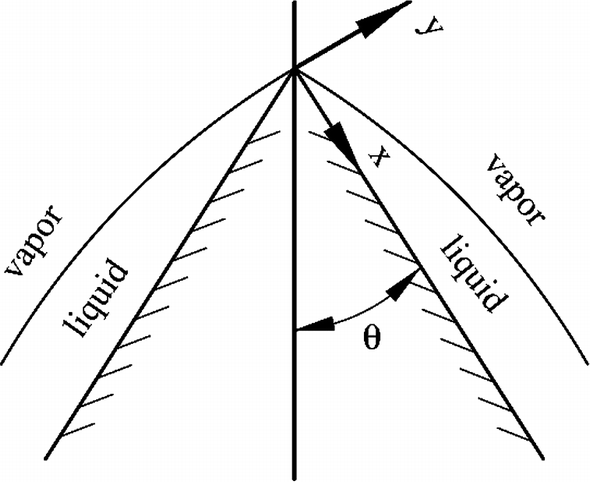

A saturated vapor condenses on the outside surface of a constant-temperature cone (see Fig. P7.17). Neglecting vapor shear stress at the liquid–vapor interface and the subcooling effect, obtain a single differential equation relating local film thickness to the temperature difference, the fluid properties, and the distance from the apex of the cone (hint: make assumptions similar to those made for the Nusselt Theory).

Fig. P7.17

-

7.18.

During laminar film condensation on the outer surface of a sphere, the condensation starts from the top of the sphere and the condensate eventually drips from the bottom of the sphere. When the condensate flows down along the spherical surface, both the driving force and the width of the liquid film vary. Derive the average heat transfer coefficient for this case, and compare your result with Eq. (7.197).

-

7.19.

For laminar film condensation occurring on a vertical surface, write down an appropriate set of governing equations and boundary conditions that could be solved to predict the variation of the film thickness and heat transfer coefficient with x for the following different boundary conditions.

-

a.

The cold surface temperature Tw is constant.

-

b.

There is a constant heat flux at the cold surface.

-

c.

The back of the cold surface is subjected to convective cooling with a coolant temperature of \(T_{\infty }\) and heat transfer coefficient of hc. The thickness of the cold wall can be neglected.

-

a.

-

7.20.

The process of condensation inside a vertical tube is complex. Build a reasonable model; write governing equations and boundary conditions for the model.

-

7.21.

The effect of liquid subcooling was neglected in the Nusselt analysis. Starting from the energy equation for liquid film with convection terms accounted for, show that the energy balance in the liquid film is Eq. (7.110). If the temperature profile in the liquid can be assumed to be linear like Eq. (7.111), show that the Nusselt analysis is still valid provided that the latent heat, \(h_{{\ell {\text{v}}}}\), is replaced by \(h_{{\ell {\text{v}}}}^{\prime }\) as defined in Eq. (7.113).

-

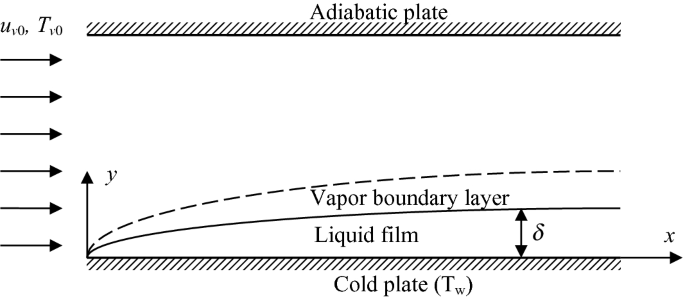

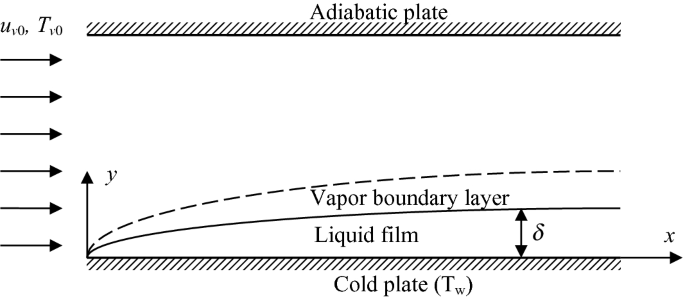

7.22.

A pure vapor flows into a horizontal channel formed by two parallel plates (see Fig. P7.22) with uniform velocity (\(u_{\infty }\)) and temperature (\(T_{\infty }\)). The bottom plate is maintained at a temperature, Tw, below the saturation temperature, while the upper plate is adiabatic. Condensation occurs on the surface of the bottom plate, and the condensate is dragged by the vapor and flows to the positive x-direction. The thickness of the liquid film is much smaller than the distance between the two plates (\(\delta \ll H\)). Both velocity and temperature distribution in the liquid film can be assumed to be linear. The shear stress at the liquid–vapor interface can be estimated by \(\tau_{\delta } = 0.5f\rho_{\text{v}} (u_{\text{v}} - u_{\delta } )^{2} + \dot{m}_{\delta }^{\prime \prime} (u_{\text{v}} - u_{\delta } )\), where the friction coefficient \(f = C {Re}^{n}\) (C and n are constants), \(u_{\delta }\) is the axial velocity at interface, and \(\dot{m}_{\delta }^{\prime \prime}\) is rate of condensation. Obtain the ordinary differential equation that governs the liquid film thickness.

Fig. P7.22

-

7.23.

A condenser is made of a vertical array of 200 horizontal tubes, each 0.5 m long and with diameters of 10 mm. If the condenser is meant to condense saturated steam at 0.5 bars and the cooling tubes are at 25 °C, what is the average condensation rate for a single tube of the condenser?

-

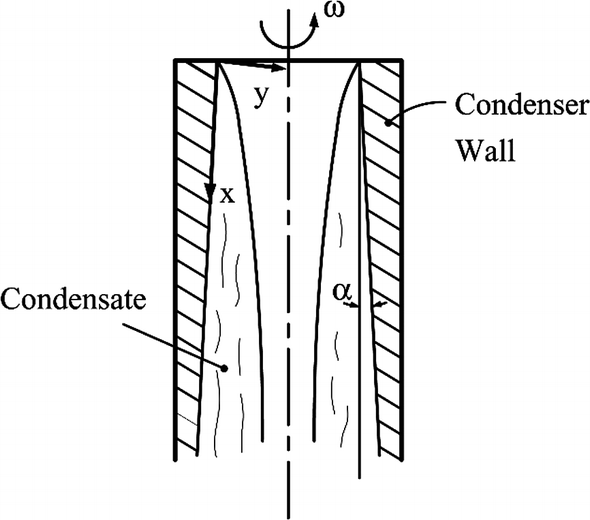

7.24.

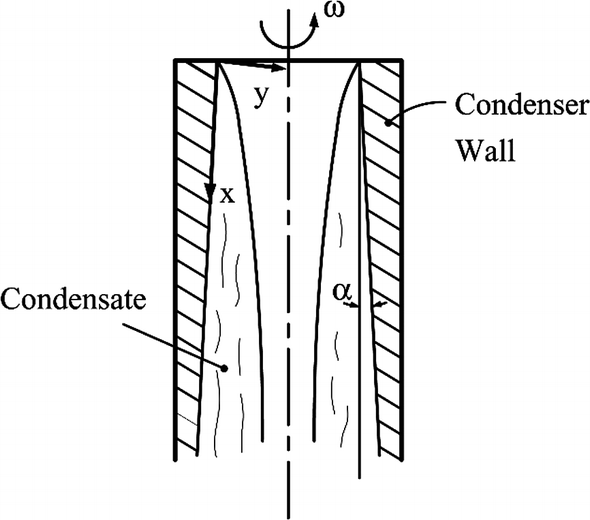

The condenser section of a rotating heat pipe is shown in Fig. P7.24. The liquid condensate is removed by centrifugal force, and the effect of gravity can be neglected. The temperature of the condenser wall uniformly equals Tw, and the vapor is saturated. The effect of vapor flow on the film condensation can be neglected. Assuming the circumferential velocity and temperature gradient are negligible, find the velocity profile in the liquid condensate.

Fig. P7.24

-

7.25.

Heat conduction in the condenser wall was neglected in Problem 7.24 by assuming the entire condenser wall is at a uniform temperature. If the outer surface of the condenser wall is maintained at Tw, repeat the above problem while considering heat conduction in the condenser wall. Heat conduction in the axial direction can be neglected for simplicity.

-

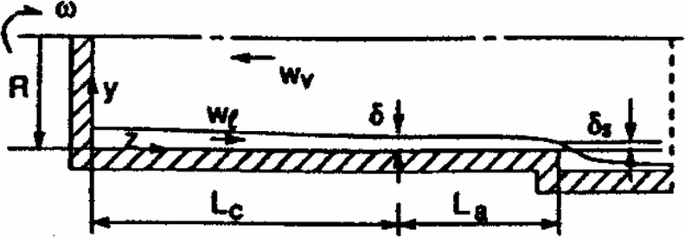

7.26.

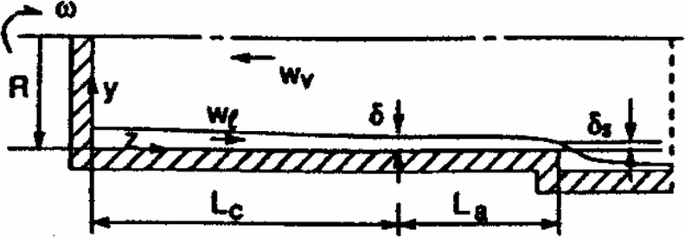

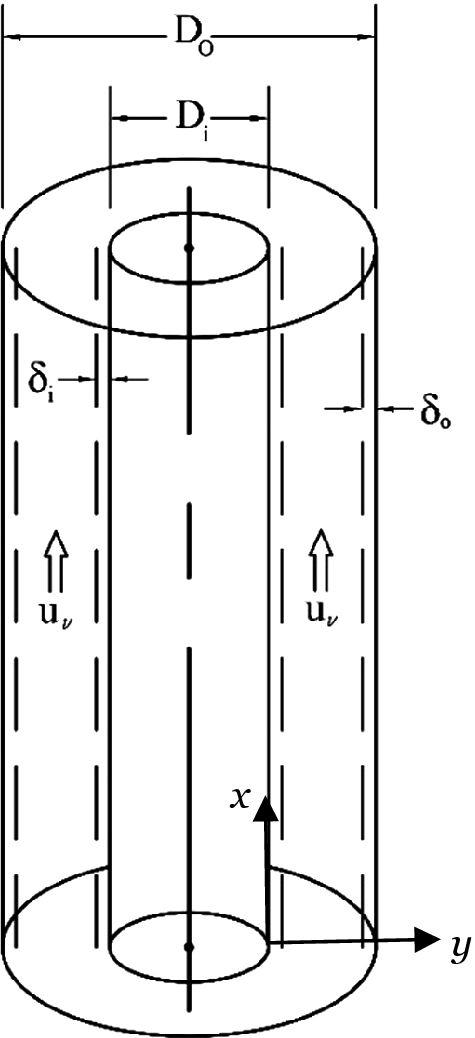

In a rotating heat pipe, thermal energy transport relies on the evaporation and condensation of a small amount of working fluid, whereas the condensate return relies on the centrifugal force. In the cylindrical section, including condenser and adiabatic zones with a step at the position connecting the evaporator, the condensate return is maintained by centrifugal forces acting on the liquid film with varying film thickness, which results in a hydrostatic pressure change in the film. The coordinate system for annular flow is shown in Fig. P7.26. It can be assumed that (1) the condensate film flow is laminar, (2) the liquid film thickness is much smaller than the heat pipe’s inner radius, (3) the radial heat flux is uniform, (4) inertial and convective effects in the liquid are neglected, and (5) the gravitational force is negligible compared to the centrifugal force. Obtain the liquid film thickness along the axial direction.

Fig. P7.26

-

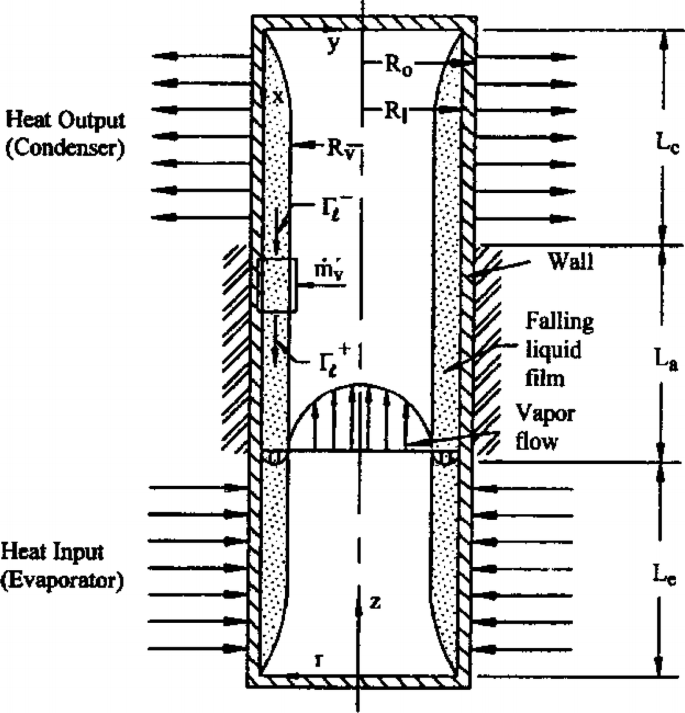

7.27.

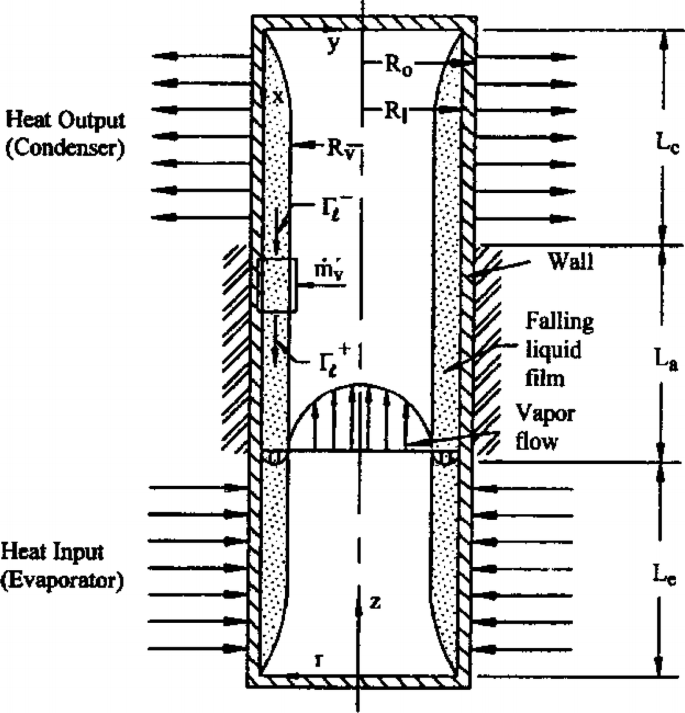

Under an ideal situation, no liquid accumulates at the bottom of the thermosyphon (see Fig. P7.27). It is assumed that (1) the vapor condensation is filmwise with no interfacial waves, (2) liquid subcooling is negligible, (3) inertial effects in the liquid are negligible, (4) convection effects in the liquid are negligible, (5) the liquid film thickness is much smaller than the vapor space radius, and (6) the vapor density is much smaller than the liquid density. Specify the governing equations for flow and heat transfer in the liquid film in the cylindrical coordinate system. Analyze heat transfer in the liquid film using the Nusselt-type solution procedure.

Fig. P7.27

-

7.28.

The reflux condensation in a small diameter tube is shown in Fig. P7.28. It is assumed that the shear stress on the surface of the liquid film is negligible, and all other assumptions for the Nusselt analysis are applicable. Derive the differential equation for the liquid film thickness distribution, and specify the corresponding boundary conditions. You do not need to consider the liquid layer at the lower portion of the cross section.

Fig. P7.28

-

7.29.

The mass flux at the liquid–vapor interface for condensation of condensable vapor and noncondensable gas can be obtained from Eq. (7.208). Show that the mass flux can also be obtained from Eq. (7.211) if the mixture of condensable vapor and noncondensable gas can be treated as ideal gas.

-

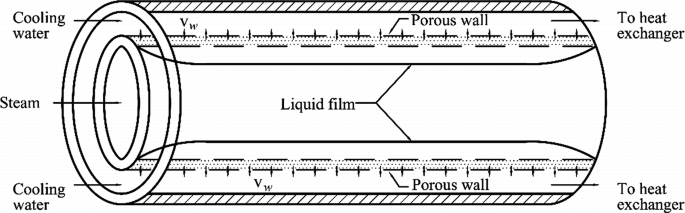

7.30.

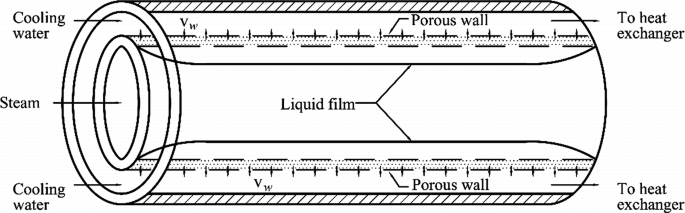

Consider a system using an annular pipe with its inner wall made of a porous material (Fig. P7.30). In this system, steam flows through a porous pipe and cooling liquid flows through the annular region between a solid outer pipe and the porous inner pipe. The steam condenses onto the inner wall of the porous material, because the cooling liquid keeps the temperature of the porous wall below that of the steam’s saturation temperature. A small pressure drop is maintained between the steam and the cooling flow in order to drive the condensate through the porous material to the annular region, where it mixes with the cooling liquid and is swept away to a heat exchanger. Assuming the suction velocity at wall v ≅ vw = const, extend the Nusselt analysis for laminar film condensation inside a tube with a constant-temperature porous wall. The shear stress at the liquid–vapor interface decreases due to condensation. Assuming that the properties of the fluid remain constant and that the curvature of the condensate film can be neglected, develop the dimensionless velocity and temperature distributions using the following nondimensional variables:

Fig. P7.30

$$y^{*} = - \frac{{yv_{\text{w}} }}{{\alpha_{\ell } }}\,, u^{*} = - \frac{{u_{\ell } }}{{v_{\text{w}} }}\,, T^{*} = \frac{{T - T_{\text{w}} }}{{T_{\text{sat}} - T_{\text{w}} }}\,, N_{2} = \frac{{\tau_{\delta } \alpha_{\ell } }}{{\mu_{\ell } v_{\text{w}}^{2} }}\,, \delta^{*} = \frac{{ - v_{\text{w}} \delta }}{{\alpha_{\ell } }}$$(7.221) -

7.31.

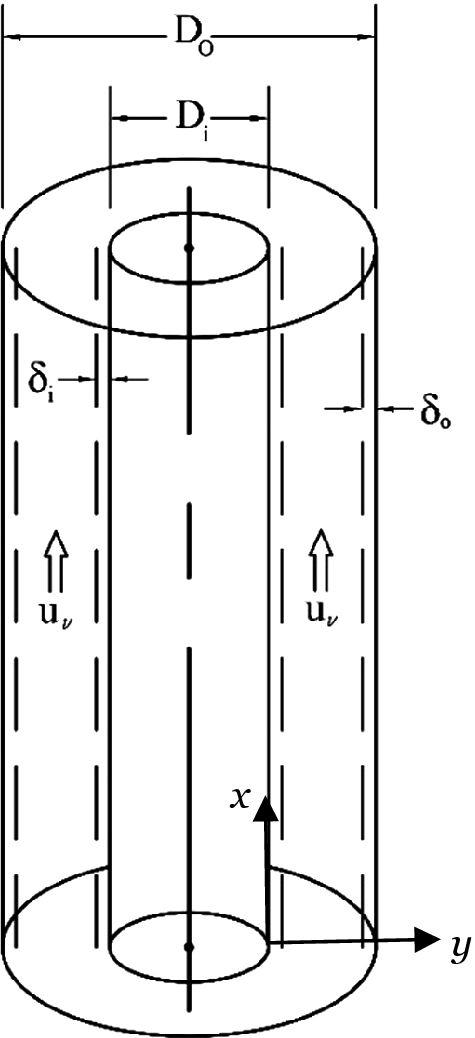

Consider the use of an annular pipe as a condenser for microgravity application, with vapor shear as the driving force for condensate removal as shown in Fig. P7.31. Here, saturated vapor enters the annular region at x = 0, while the inner and outer walls are held at constant temperatures Tw,i and Tw,o, respectively. A pressure drop occurs along the x-axis due to the friction at the walls. Also, the vapor temperature, density, and viscosity were all assumed to be constant. It is assumed that the film thicknesses, δi at inner wall and δo at outer wall, are small compared to the inner diameter of the annulus, Di. Neglect inertia term and convection effect in the liquid films and obtain the following expression for the inner and outer walls, respectively:

Fig. P7.31

$$\frac{{{\text{d}}\, {Re}_{{\ell ,{\text{i}}}} }}{{{\text{d}}x}} = \frac{{k_{\ell } \left( {T_{\text{sat}} - T_{\text{w,i}} } \right)}}{{h_{{\ell {\text{v}}}} \mu_{\ell } \delta_{\text{i}} }} = \frac{{Ja_{i} }}{{Pr_{\ell } \delta_{\text{i}} }} = \frac{{N_{{1{\text{i}}}} }}{{\delta_{\text{i}} }}$$(7.222)$$\frac{{{\text{d}}\,{Re}_{{\ell,{\text{o}}}} }}{{{\text{d}}x}} = \frac{{k_{\ell } \left( {T_{\text{s}} - T_{\text{w,o}} } \right)}}{{h_{{\ell {\text{v}}}} \mu_{\ell } \delta_{\text{o}} }} = \frac{{Ja_{o} }}{{Pr_{\ell } \delta_{\text{o}} }} = \frac{{N_{{1{\text{o}}}} }}{{\delta_{\text{o}} }}$$(7.223)where Ja is the Jacob number \(c_{{{\text{p}}\ell }} (T_{\text{sat}} - T_{\text{w}} )/h_{{\ell {\text{w}}}}\) and N1 is the ratio of the Jacob number to the liquid Prandtl number.

-

7.32.

Prove the following expression for Problem 7.31 using the mass balance between the liquid and vapor:

$${Re}_{\text{v,h}} = {Re}_{\text{v,e,h}} - 4\frac{{\mu_{\ell } }}{{\mu_{\text{v}} }}\frac{{K^{*} }}{{1 + K^{*} }}{Re}_{{\ell,{\text{i}}}} - 4\frac{{\mu_{\ell } }}{{\mu_{\text{v}} }}\frac{1}{{1 + K^{*} }}{Re}_{{\ell ,{\text{o}}}}$$(7.224)where

$$K^{*} = \frac{{D_{\text{i}} }}{{D_{\text{o}} }}$$(7.225) -

7.33.

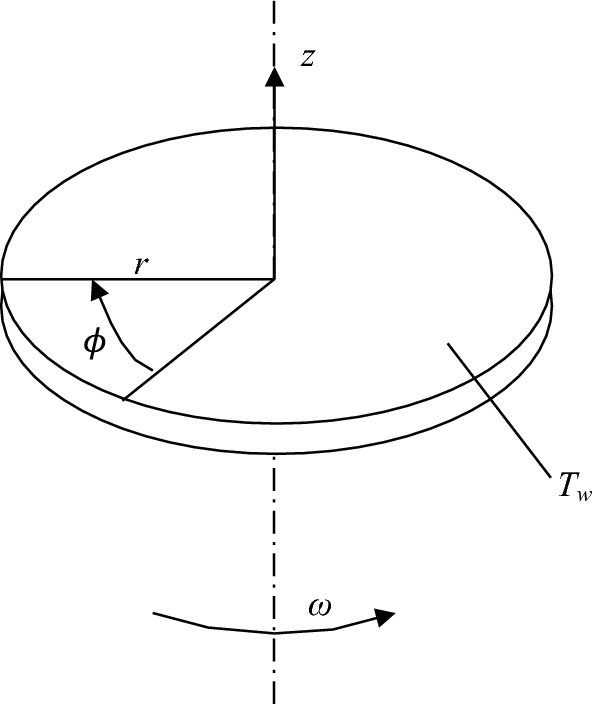

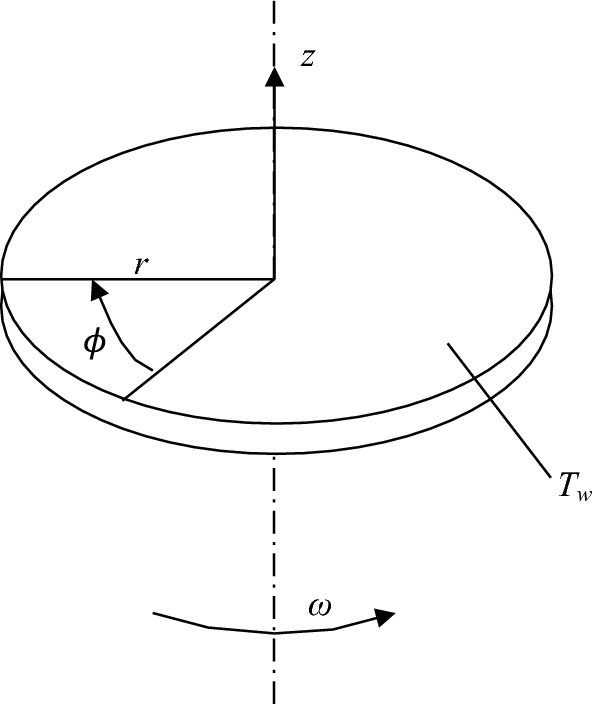

One method to create artificial gravity for condensate removal involves use of a centrifugal field that is, a rotating disk. Consider a cooled rotating disk in a large quiescent body of pure saturated vapor, as shown in Fig. P7.33. The liquid forms a continuous film on the disk, and the fluid in this film will move radially outward due to the centrifugal force. Develop the conservation equations for mass, momentum in the r-, \(\phi\)-, and z-directions and energy for an incompressible, steady, and constant-property liquid including the associated boundary conditions.

Fig. P7.33

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Faghri, A., Zhang, Y. (2020). Condensation. In: Fundamentals of Multiphase Heat Transfer and Flow. Springer, Cham. https://doi.org/10.1007/978-3-030-22137-9_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-22137-9_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22136-2

Online ISBN: 978-3-030-22137-9

eBook Packages: EngineeringEngineering (R0)