Abstract

This chapter starts with definitions of various parameters for two-phase flow and flow patterns in vertical and horizontal tubes. This is followed by two-phase flow models as well as prediction of pressure drops and void fractions. Finally, the two-phase flow regimes and heat transfer characteristics for forced convective condensation and boiling at both macro- and microscale levels are presented.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

References

Awad, M. M., & Muzychka, Y. S. (2005a). Bounds on two-phase flow: Part I fractional pressure gradient in circular tubes. In Proceedings of International Mechanical Engineering Congress and Exposition, Orlando, FL (DVD).

Awad, M. M., & Muzychka, Y. S. (2005b). Bounds on two-phase flow: Part II void fraction in circular tubes. In Proceedings of International Mechanical Engineering Congress and Exposition, Orlando, FL (DVD).

Bandel, J. (1973). Druckverlust ünd Wärmeübergang bei der Verdampfung siedender Kältemittel im durchströmten waagerechten Rohr, Doctoral Dissertation, Universität Karlsruhe.

Baroczy, C. J. (1965). Correlation of liquid fraction in two-phase flow with applications to liquid metals. Chemical Engineering Progress Symposium Series, 61, 179–191.

Barnea, D., Luninski, Y., & Taitel, Y. (1983). Flow pattern in horizontal and vertical two phase flow in small diameter pipes. Canadian Journal of Chemical Engineering, 61, 617–620.

Beattie, D. R. H., & Whalley, P. B. (1982). A simple two-phase frictional pressure drop calculation method. International Journal of Multiphase Flow, 8, 83–87.

Begg, E., Khrustalev, D., & Faghri, A. (1999). Complete condensation of forced convection two-phase flow in a miniature tube. Journal of Heat Transfer, 121, 904–915.

Bergles, A. E., & Kandlikar, S. G. (2005). On the nature of critical heat flux in microchannels. Journal of Heat Transfer, 127, 102–107.

Bowers, M. B., & Mudawar, I. (1994). High flux boiling in low flow rate, low pressure drop mini-channel and microchannel heat sinks. International Journal of Heat and Mass Transfer, 37, 321–332.

Breber, G., Palen, J. W., & Taborek, J. (1980). Prediction of horizontal tubeside condensation of pure components using flow regime criteria. Journal of Heat Transfer, 102, 471–476.

Butterworth, D. (1975). A comparison of some void-fraction relationships for cocurrent gas-liquid flow. International Journal of Multiphase Flow, 1(6), 845–850.

Chang, J. S., & Watson, A. (1994). Electromagnetic hydrodynamics. IEEE Transactions on Dielectrics and Electrical Insulation, 1, 871–895.

Chen, J. C. (1963). A correlation for boiling heat transfer to saturated fluids in convective flow. In ASME preprint 63-HT-34, Presented at 6th National Heat Transfer Conference, Boston, MA.

Chen, Y., Groll, M., Mertz, R., & Kulenovic, R. (2003). Force analysis for isolated bubbles growing from smooth and evaporator tubes. Transaction of the Institute of Fluid-Flow Machinery, 112, 57–74.

Chisholm, D. (1967). A theoretical basis for the Lockhart-Martinelli correlation for two-phase flow. International Journal of Heat and Mass Transfer, 10, 1767–1778.

Chisholm, D. (1973a). Pressure gradients due to friction during the flow of evaporating two-phase mixtures in smooth tubes and channels. International Journal of Heat and Mass Transfer, 16, 347–348.

Chisholm, D. (1973b). Void fraction during two-phase flow. Journal of Mechanical Engineering Science, 15, 235–236.

Chung, P. M. Y., & Kawaji, M. (2004). The effect of channel diameter on adiabatic two-phase flow characteristics in microchannels. International Journal of Multiphase Flow, 30, 735–761.

Collier, J. G., & Thome, J. R. (1994). Convective boiling and condensation (3rd ed.). Oxford, UK: Oxford University Press.

Cotton, J., Robinson, A. J., Shoukri, M., & Chang, J. S. (2005). A two-phase flow pattern map for annular channels under a DC applied voltage and the application to electrohydrodynamic convective boiling analysis. International Journal of Heat and Mass Transfer, 48, 5563–5579.

Davis, E. J., & Anderson, G. H. (1966). The incipience of nucleate boiling in forced convection flow. AIChE Journal, 12, 774–780.

Dobson, M. K., & Chato, J. C. (1998). Condensation in smooth horizontal tubes. Journal of Heat Transfer, 120, 193–213.

Dupont, V., & Thome, J. R. (2004). Evaporation in microchannels: Influence of the channel diameter on heat transfer. Microfluidics and Nanofluidics, 1, 119–127.

Faghri, A. (2016). Heat pipe science and technology (2nd ed.). Columbia, MO: Global Digital Press.

Feng, Z. P., & Serizawa, A. (1999). Visualization of two-phase flow patterns in an ultra-small tube. In Proceedings of the 18th Multiphase Flow Symposium of Japan (pp. 33–36).

Forster, H. K., & Zuber, N. (1955). Dynamics of vapor bubbles and boiling heat transfer. AIChE Journal, 1, 531–535.

Friedel, L. (1979). Improved friction pressure drop correlations for horizontal and vertical two-phase pipe flow. In European Two-Phase Flow Group Meeting, Paper E2, Ispra, Italy.

Gersey, C. O., & Mudawar, I. (1993). Orientation effects on critical heat flux from discrete, in-line heat sources in a flow channel. Journal of Heat Transfer, 115, 973–985.

Golan, L. P., & Stenning, A. H. (1969). Two-phase vertical flow maps. Proceedings of the Institute of Mechanical Engineers, 184(3C), 110–116.

Hashizume, K. (1983). Flow pattern, void fraction and pressure drop of refrigerant two-phase flow in a horizontal pipe, Part I: Experimental data. International Journal of Multiphase Flow, 9, 399–410.

Hewitt, G. F. (1998). Multiphase fluid flow and pressure drop. In Heat exchanger design handbook (Vol. 2). New York, NY: Begell House.

Hewitt, G. F., & Roberts, D. N. (1969). Studies of two-phase flow patterns by simultaneous X-ray and flash photography. AERE-M 2159, HMSO.

Hsu, Y. Y. (1962). On the size range of active nucleation cavities on a heating surface. Journal of Heat Transfer, 84, 207–216.

Jaster, H., & Kosky, P. G. (1976). Condensation heat transfer in a mixed flow regime. International Journal of Heat and Mass Transfer, 19, 95–99.

Kandlikar, S. G. (1990). A general correlation for two-phase flow boiling heat transfer coefficient inside horizontal and vertical tubes. Journal of Heat Transfer, 112, 219–228.

Kandlikar, S. G. (1991). Development of a flow boiling map for subcooled and saturated flow boiling of different fluids in circular tubes. Journal of Heat Transfer, 113, 190–200.

Kattan, N., Thome, J. R., & Favrat, D. (1998a). Flow boiling in horizontal tubes: Part 1—Development of adiabatic two-phase flow pattern map. Journal of Heat Transfer, 120, 140–147.

Kattan, N., Thome, J. R., & Favrat, D. (1998b). Flow boiling in horizontal tubes: Part 2—New heat transfer data for five refrigerants. Journal of Heat Transfer, 120, 148–155.

Kattan, N., Thome, J. R., & Favrat, D. (1998c). Flow boiling in horizontal tubes: Part 3—Heat transfer model based on flow pattern. Journal of Heat Transfer, 120, 156–165.

Katto, Y., & Ohno, H. (1984). An improved version of the generalized correlation of critical heat flux for the forced convection boiling in uniformly heated vertical tubes. International Journal of Heat and Mass Transfer, 27, 1641–1648.

Kawaji, M., & Chung, P. M. Y. (2004). Adiabatic gas-liquid flow in microchannels. Microscale Thermophysical Engineering, 8, 239–257.

Kew, P. A., & Cornwell, K. (1997). Correlations for prediction of boiling heat transfer in small diameter channels. Applied Thermal Engineering, 17, 705–715.

Khrustalev, D., & Faghri, A. (1994). Thermal analysis of a micro heat pipe. Journal of Heat Transfer, 116, 189–198.

Khrustalev, D., & Faghri, A. (1996). High flux evaporative mini-channel heat sink with axial capillary grooves. Journal of Enhanced Heat Transfer, 3, 221–232.

Khrustalev, D., & Faghri, A. (1997). Boiling heat transfer in miniature axially-grooved rectangular channel with discrete heat sources. Journal of Enhanced Heat Transfer, 4, 163–174.

Klausner, J. F., Mei, R., Bernhard, D. M., & Zeng, L. Z. (1993). Vapor bubble departure in forced convection boiling. International Journal of Heat and Mass Transfer, 36, 651–662.

Kocamustafaogullari, G., & Ishii, M. (1983). Interfacial area and nucleation site density in boiling systems. International Journal of Heat and Mass Transfer, 26, 1377–1387.

Koşar, A., Kuo, C. J., & Peles, Y. (2005). Boiling heat transfer in rectangular microchannels with reentrant cavities. International Journal of Heat and Mass Transfer, 48, 4867–4886.

Lazarek, G. M., & Black, S. H. (1982). Evaporative heat transfer, pressure drop and critical heat flux in a small vertical tube with R-113. International Journal of Heat and Mass Transfer, 25, 945–960.

Liu, D., Lee, P. S., & Garimella, S. V. (2005). Prediction of the onset of nucleate boiling in microchannel flow. International Journal of Heat and Mass Transfer, 48, 5134–5149.

Lockhart, R. W., & Martinelli, R. C. (1949). Proposed correlation of data for isothermal two-phase, two-component flow in pipes. Chemical Engineering Progress Symposium Series, 45, 39–48.

Maddox, D. E., & Mudawar, I. (1989). Single- and two-phase convective heat transfer from smooth and enhanced microelectronic heat sources in a rectangular channel. Journal of Heat Transfer, 111, 1045–1052.

Mei, R., & Klausner, J. F. (1994). Shear lift force on spherical bubbles. International Journal of Heat Fluid Flow, 15, 62–65.

Moser, K. W., Webb, R. L., & Na, B. (1998). A new equivalent reynolds number model for condensation in smooth tubes. Journal of Heat Transfer, 120, 410–417.

Munoz-Cobol, J. L., Herranz, L., Sancho, J., Takachenko, I., & Verdu, G. (1996). Turbulent vapor condensation with noncondensable gases in vertical tubes. International Journal of Heat and Mass Transfer, 39, 3249–3260.

Plesch, D., Bier, W., Seidel, D., & Schubert, K. (1991). Miniature heat pipes for heat removal from microelectronic circuits. In Micromechanical Sensors, Actuators, and Systems, DSC-32 (pp. 303–313). New York: ASME.

Premoli, A., Francesco, D., & Prina, A. (1971). A dimensionless correlation for determining the density of two-phase mixtures. Thermotecnica, 25, 17–26.

Qu, W., & Mudawar, I. (2004). Measurement and correlation of critical heat flux in two-phase micro-channel heat sinks. International Journal of Heat and Mass Transfer, 47, 2045–2059.

Rabas, T. J., & Minard, P. G. (1987). Two types of flow instabilities occurring inside horizontal tubes with complete condensation. Heat Transfer Engineering, 8, 40–49.

Riehl, R. R., & Ochterbeck, J. M. (2002). Experimental investigation of the convective condensation heat transfer in microchannel flows. In The 9th Brazilian Congress of Thermal Engineering and Sciences, Caxambu, MG, Paper CIT02-0495.

Serizawa, A., & Feng, Z. P. (2001). Two-phase flow in micro-channels. In Proceedings of the 4th International Conference on Multiphase Flow, New Orleans, LA.

Serizawa, A., Feng, Z., & Kawara, Z. (2000). Two-phase flow in microchannels. Experimental Thermal and Fluid Science, 26, 703–714.

Shah, M. M. (1979). A general chart correlation for heat transfer during condensation inside pipes. International Journal of Heat and Mass Transfer, 22, 547–556.

Shah, R. K., & London, A. L. (1978). Laminar flow forced convection in ducts. In Advances in Heat Transfer, Suppl. 1. San Diego, CA: Academic Press.

Shin, J. S., & Kim, M. H. (2005). An experimental study of flow condensation heat transfer inside circular and rectangular mini-channels. Heat Transfer Engineering, 26, 36–44.

Situ, R., Hibiki, T., Ishii, M., & Mori, M. (2005). Bubble lift-off size in forced convective subcooled boiling flow. International Journal of Heat and Mass Transfer, 48, 5536–5548.

Soliman, H. M. (1974). Analytical and experimental studies of flow patterns during condensation inside horizontal tubes, Ph.D. Dissertation, Kansas State University, Manhattan, KS.

Tabatabai, A., & Faghri, A. (2001). A new two-phase flow map and transition boundary accounting for surface tension effects in horizontal miniature and micro tubes. Journal of Heat Transfer, 123, 958–968.

Taitel, Y., & Dukler, A. E. (1976). A model for predicting flow regime transitions in horizontal and near horizontal gas-liquid flow. AIChE Journal, 22, 47–55.

Tandon, T. N., Varma, H. K., & Gupta, C. P. (1982). A new flow regime map for condensation inside horizontal tubes. Journal of Heat Transfer, 104, 763–768.

Teng, H., Cheng, P., & Zhao, T. S. (1999). Instability of condensate film and capillary blocking in small-diameter-thermosyphon condensers. International Journal of Heat and Mass Transfer, 42, 3071–3083.

Thome, J. R. S. (1964). Prediction of pressure drop during forced circulation boiling of water. International Journal of Heat and Mass Transfer, 7, 709–724.

Thome, J. R. (2016). The heat transfer engineering data book III. Ulm: Wieland-Werke AG.

Thome, J. R., Dupont, V., & Jacobi, A. M. (2004). Heat transfer model for evaporation in microchannels. Part I: Presentation of model. International Journal of Heat and Mass Transfer, 47, 3375–3385.

Thome, J. R., & El Hajal, J. (2003). Two-phase flow pattern map for evaporation in horizontal tubes: Latest version. Heat Transfer Engineering, 24, 3–10.

Tran, T. N., Wambsganns, M. W., & France, D. M. (1996). Small circular-and rectangular-channel boiling with two refrigerants. International Journal of Multiphase Flow, 22, 485–498.

Triplett, K. A., Ghiaasiaan, S. M., Abdel-Khalik, S. I., & Sadowski, D. L. (1999). Gas-liquid two-phase flow in microchannels—Part I: Two-phase flow pattern. International Journal of Multiphase Flow, 25, 377–394.

Turner, J. M. (1966). Annular two-phase flow. Ph.D. Dissertation, Dartmouth College, Hanover, NH.

Vasiliev, L. L, Grakovich, L. P., & Khrustalev, D. K. (1984). Gravity-assisted heat pipes for solar energy collectors. In Proceedings of the 5th International Heat Pipe Conference (Vol. 3, pp. 19–24). Tsukuba, Japan, Pre-prints.

Vlasie, C., Macchi, H., Guilpart, J., & Agostini, B. (2004). Flow boiling in small diameter channels. International Journal of Refrigeration, 27, 191–201.

Wambsganss, M. W., Jendrzejczyk, J. A., & France, D. M. (1991). Two-phase flow patterns and transitions in a small, horizontal, rectangular channel. International Journal of Multiphase Flow, 17, 327–342.

Wilmarth, T., & Ishii, M. (1994). Two-phase flow regimes in narrow rectangular vertical and horizontal channels. International Journal of Heat and Mass Transfer, 37, 1749–1758.

Yu, W., France, D. M., Wambsgans, M. W., & Hull, J. R. (2002). Two-phase pressure drop, boiling heat transfer, and critical heat flux to water in a small-diameter horizontal tube. International Journal of Multiphase Flow, 28, 927–941.

Zeng, L. Z., Klausner, J. F., Bernhard, D. M., & Mei, R. (1993). A unified model for the prediction of bubble detachment diameters in boiling systems - II. Flow boiling. International Journal of Heat and Mass Transfer, 36, 2271–2279.

Zhang, Y., Faghri, A., & Shafii, M. B. (2001). Capillary blocking in forced convective condensation in horizontal miniature channels. Journal of Heat Transfer, 123, 501–511.

Zivi, S. M. (1964). Estimation of steady-state void fraction by means of the principle of minimum energy production. Journal of Heat Transfer, 86, 247–252.

Zuber, N. (1961). The dynamics of vapor bubbles in nonuniform temperature fields. International Journal of Heat and Mass Transfer, 2, 83–98.

Author information

Authors and Affiliations

Corresponding author

Problems

Problems

-

10.1.

Express slip ratio in terms of the total cross-sectional area, total volume flow rate, void fraction, and vapor velocity.

-

10.2.

Redo Problem 10.1 using the mass flux instead of the total volume flow rate.

-

10.3.

Express volumetric flow fraction in terms of the total cross-sectional area, total volume flow rate, and gas superficial velocity.

-

10.4.

Consider liquid–vapor two-phase flow. Find the expression for mass flux as a function of the quality, the individual phase velocities, and the densities.

-

10.5.

Express total volumetric flux in terms of the individual mass flow rates, the total cross-sectional area, and the phase densities.

-

10.6.

Determine the flow regime for upward flow of 10 kg/s of R-11 in a vertical 0.1 m diameter tube at 10 bar and 25% quality.

-

10.7.

For a horizontal miniature tube of 1 mm inner diameter, determine the flow regime for 1.5 × 10−3 kg/s of water–steam at 1 atm and 10% quality.

-

10.8.

For a horizontal circular tube with inner diameter of 5 cm (D = 0.05 m), determine the flow regime for 1.5 × 10−3 kg/s of steam‐water flow at 1 atm and 59% quality.

-

10.9.

The flow of 0.1 kg/s of air and 5 kg/s of water at 20 °C and 1 atm at a given point in a horizontal channel is in the bubbly regime. Describe qualitatively how the two-phase flow should change to achieve stratified flow.

-

10.10.

Determine the pressure drop due to friction for a 1 kg/s flow of steam–water in a 10 cm inner diameter tube at 2 atm and 40% quality.

-

10.11.

Calculate the void fraction using the homogeneous model for a two-phase water–steam flow with a quality of 35% at 15 bars.

-

10.12.

Specify the governing equations for adiabatic two-phase flow in a circular tube of constant cross-sectional area using (1) the homogeneous model and (2) the separated flow model.

-

10.13.

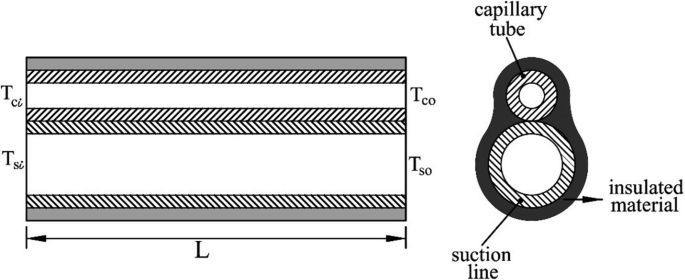

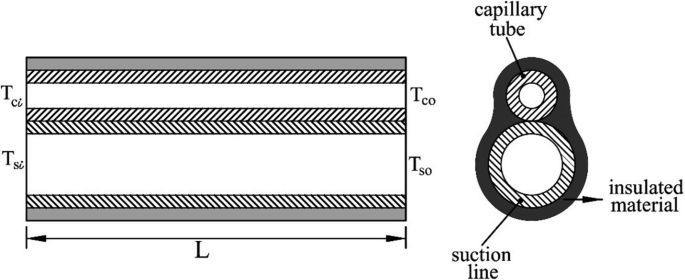

A capillary tube-suction line heat exchanger consists of a capillary tube and a suction line welded together as shown in Fig. P10.13. While evaporation takes place in the capillary tube, the suction line flow is single phase. Specify the governing equations for fluid flow and heat transfer in the system using the homogeneous model.

Fig. P10.13

-

10.14.

A mixture of steam–water flows in a 5-cm inner diameter vertical tube at 10 kg/s, 5 atm, and 10% quality. What is the void fraction?

-

10.15.

A mixture of steam–water flows in a 5-cm inner diameter vertical tube at 1 atm. The superficial velocities of the liquid and vapor are 1 and 100 m/s, respectively. Determine the void fraction using Eq. (10.105).

-

10.16.

Steam condenses at 80 °C as it flows inside a horizontal tube with an inner diameter of 5 cm. The mass flow rate is 0.5 kg/s, and the quality is x = 0.75. Find the heat transfer coefficient.

-

10.17.

Calculate the flow boiling two-phase heat transfer coefficient for a 400 kg/sm2 of R22 at a saturation temperature of −20 °C and 20% quality in an upward vertical tube with an inner diameter of 1 cm and a wall temperature of 0 °C.

-

10.18.

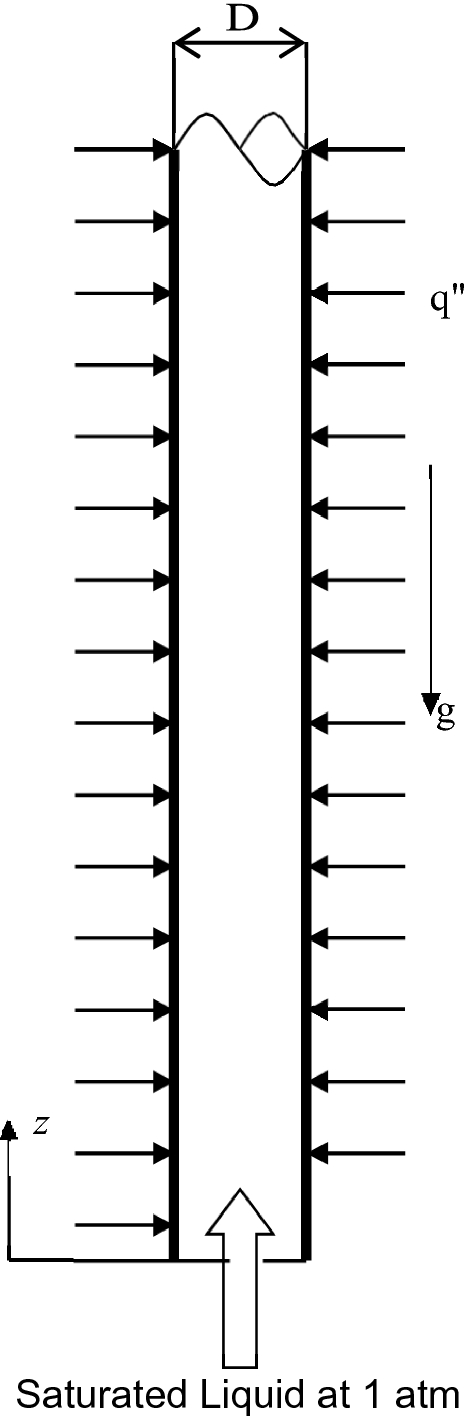

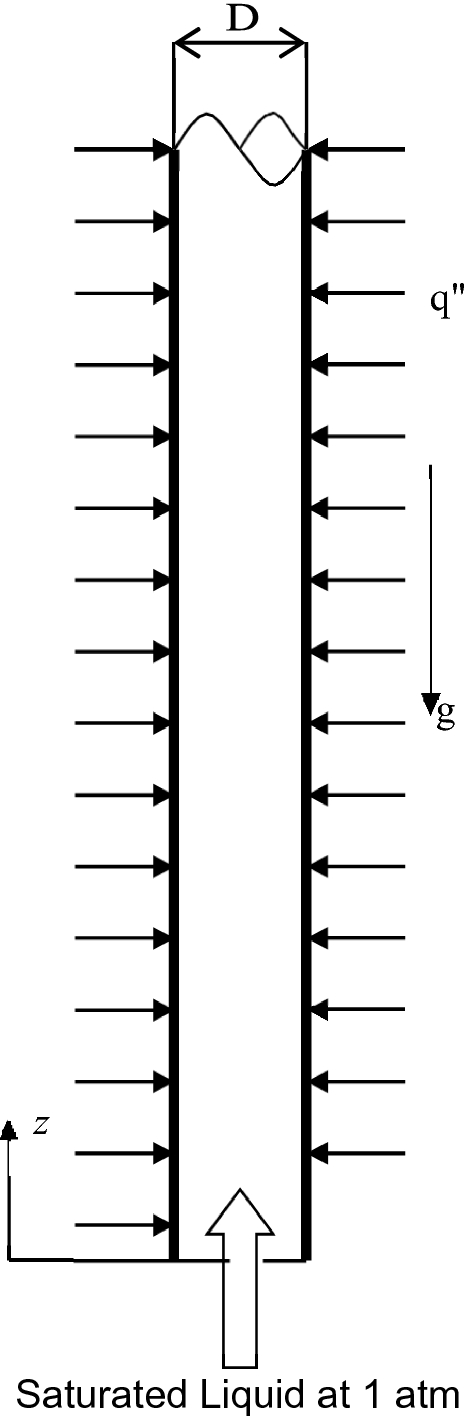

Saturated liquid water at 1 atm enters a vertical tube evaporator (circular cross section) with a constant heat flux of \(q^{\prime\prime }\) (see Fig. P10.18). The tube inner diameter is D, and the thickness of the tube can be neglected (i.e., assume that the outer diameter of the tube is equal to the inner diameter).

Fig. P10.18

-

a.

Determine the quality of mixture as a function of distance from the inlet if the kinetic and potential energy can be neglected.

-

b.

Assuming homogeneous flow model is valid, determine the void fraction as a function of distance from the inlet.

-

c.

Develop an expression for (but not evaluate) the gravitational pressure drop across the tube for a given length, L.

-

d.

If the mass flow rate is 0.05 kg/s, heat flux is 100 kW/m2, and the inner diameter of the tube is 2 cm, determine the minimum length of the tube to completely evaporate the liquid.

-

a.

-

10.19.

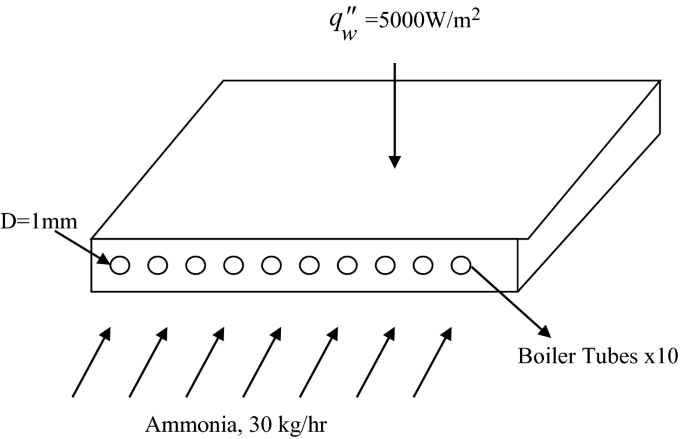

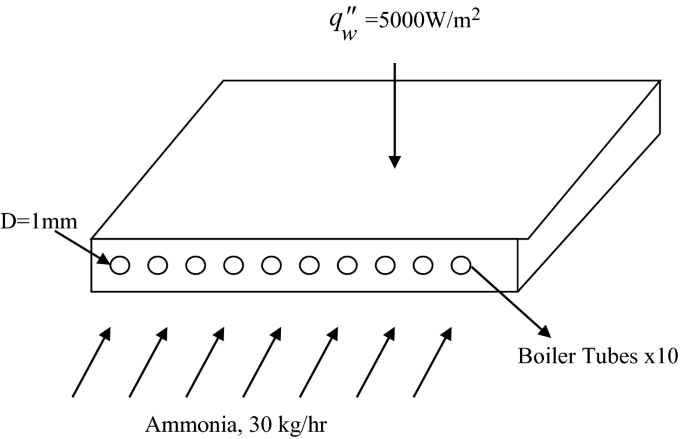

A stainless steel heat exchanger (Fig. P10.19) is being used as a flow boiler. The evaporant flows through 10 tubes with a liquid counterflow. Find the heat transfer coefficient when the quality, x, is 0.5. The evaporant is ammonia at 200 K, and the evaporant passage effective diameter is 1 mm. The wall heat flux is 5000 W/m2.

Fig. P10.19

-

10.20.

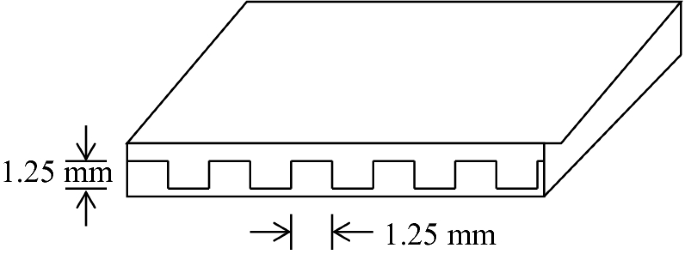

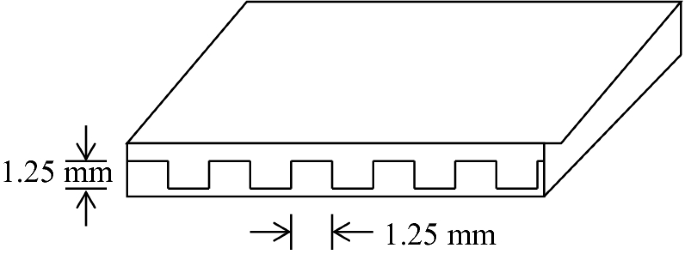

You are given a flow boiler that is fed with saturated liquid ammonia at 200 K. 100% saturated vapor exits the boiler. The boiler has 547 passages, each of which is 1.25 mm high and 1.25 mm wide. The mass flow rate of the ammonia is 11.45 kg/hr (see Fig. P10.20). Determine the phase velocity at the beginning and the end of the flow boiler. What is the percentage increase in phase velocity from the beginning to the end of the boiler?

Fig. P10.20

-

10.21.

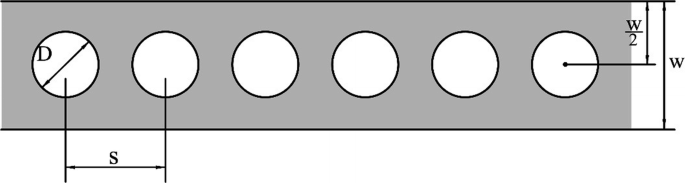

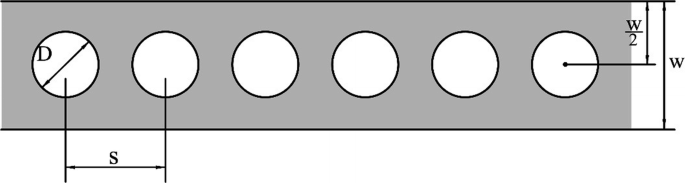

In an electronic cooling system, a row of parallel tubes with diameters of D are embedded in a horizontal plate with thickness W (Fig. P10.21). A mixture of liquid and vapor with void fraction of \(\alpha\) flows in the tube and the flow pattern is stratified. The upper surface of the plate is heated at constant heat flux while the bottom of the plate is insulated. The temperature of both liquid and vapor inside the tube is Tsat, but the heat transfer coefficients for liquid and vapor are different. Since the structure is symmetric, it is sufficient to consider only one cell with a width of S. Specify the governing equations and corresponding boundary conditions for heat conduction in the plate. You can use either the Cartesian or the cylindrical coordinate system.

Fig. P10.21

-

10.22.

The spacing between the tubes in Problem 10.21 is a critical parameter for the performance of the electronic cooling system. While small spacing allows more tubes per unit width, it also increases the conductance resistance from the top of the plate to the bottom of the plate. An optimal spacing will minimize the maximum temperature in the system. Write a computer program to solve the above conduction problem for the following parameters: D = 1 mm, W = 2 mm, \(\alpha = 0.5,\) \(q^{\prime\prime} = 10^{6} \,{\text{W/m}}^{2}\), \(h_{\ell } = 10^{4} \,{\text{W}}/{\text{m}}^{2} {\text{K}}\), \(h_{\text{v}} = 100\,{\text{W/m}}^{2} {\text{-K}}\). Perform a parametric study to find the optimal spacing for the system in Problem 10.21.

-

10.23.

A pulsating heat pipe (PHP) is a long miniature tube bent into many turns with the evaporator and condenser sections located at these turns (see Sect. 1.5.4). Since the diameter of the PHP is very small (less than 5 mm), the working fluid charged in the PHP forms vapor plugs and liquid slugs due to capillary action. Specify the governing equation to describe the oscillatory motion of an arbitrary liquid slug with a length of L in the PHP. The effects of surface tension and friction must be taken into account.

-

10.24.

Evaporation and condensation on the thin film left behind by the liquid slug are the mechanisms that sustain the pressure difference between the two ends of the liquid slug. If the vapor phase satisfies the ideal gas law, obtain the energy equation for the vapor plug. Note that the mass of the vapor plug is not constant due to evaporation and condensation.

-

10.25.

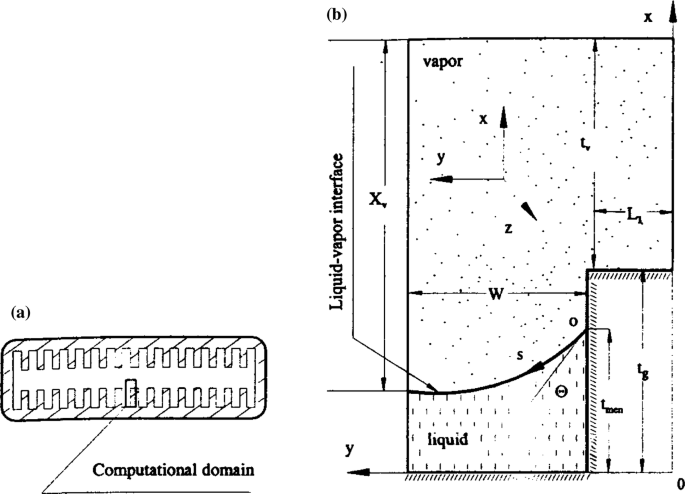

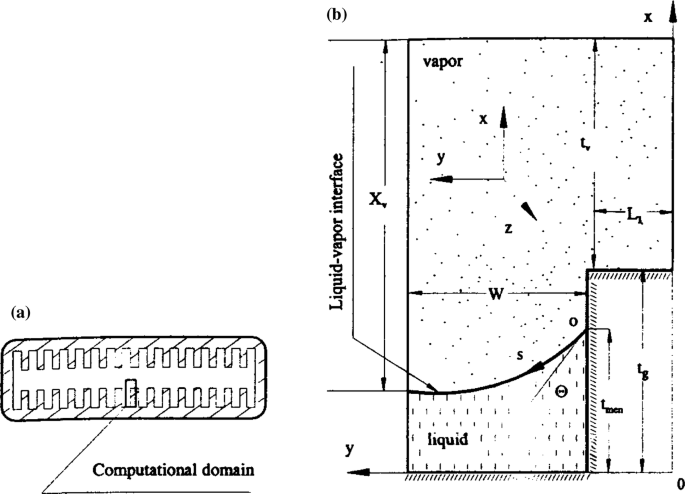

For a miniature passage with a very large length to width ratio, a fully developed flow in both vapor and liquid is very typical. A cross section of a typical miniature passage with axial rectangular grooves is shown in Fig. P10.25a. The liquid flows in the capillary microgrooves and the vapor flows in the central part of the passage free of liquid. Fluid flow in the grooved passage can be analyzed by considering a computational domain as shown in Fig. P10.25b. The vapor and liquid flow along the z-coordinate (concurrently or countercurrently). It can be assumed that (1) the fluid flow is laminar with fully developed velocity profiles, (2) the curvature of the liquid–vapor interface is constant, and (3) symmetry conditions are applicable at the three exterior boundaries of the vapor domain. Develop a steady-state mathematical model for the liquid and vapor flows that includes coupled vapor and liquid flows with shear stresses at the liquid free surface due to the vapor–liquid frictional interaction.

Fig. P10.25

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Faghri, A., Zhang, Y. (2020). Two-Phase Flow and Heat Transfer. In: Fundamentals of Multiphase Heat Transfer and Flow. Springer, Cham. https://doi.org/10.1007/978-3-030-22137-9_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-22137-9_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22136-2

Online ISBN: 978-3-030-22137-9

eBook Packages: EngineeringEngineering (R0)