Abstract

Energy as the backbone of world economic growth and development has resulted to depleting fossil fuel reserves, heavy CO2 emissions and climate change. The industrial sector consumes over 50% of global delivered energy with its consumption growing by an average of 1.4% each year. Textile industries consume 25% of the delivered electricity use of non-energy intensive manufacturing industries. These factories extensive envelopes remain unexploited even as various available technologies and strategies exist to produce cost-effective energy solutions. This study aims to provide a design framework for optimizing building form for architectural integration of Building-Integrated Photovoltaic (BIPV) in designing a textile factory. The design parameters studied include plan layout, roof type, façade type, external building features, location, size, tilt angle, orientation and shading factor. The technology studied is crystalline silicon cell with an average commercial efficiency of 15%. Visual analysis is used to analyse the integration potential of BIPV while the analysis for optimizing BIPV performance is conducted using PVGis® tool by Joint Research Center (JRC) to calculate the electricity generation potential of the BIPV systems under different combinations of values of the design parameters and Autodesk Ecotect is used to determine the self-shading factor of the different roof types. The results show that these solar photovoltaic systems could be integrated into the tilted roof, skylight, façade walls, façade glazing and external device of the factory’s building envelope. Optimum electricity is generated when modules are placed on surfaces with a tilt angle of 16° and an orientation of −4° (South −0°) with the crystalline silicon cell having a potential to generate an average monthly of 18.95 kWh/m2 of electricity. The lean-to roof with rectangular plan performs best providing the largest surface for BIPV integration with no self-shading.

Similar content being viewed by others

20.1 Introduction

Energy plays the most vital role in the economic growth, progress and development of any nation; uninterrupted energy supply is a vital issue for all countries today [1]. Energy as the backbone of world economic growth and development has resulted to depleting fossil fuel reserves, heavy CO2 emissions, climate change and a continually growing energy demand, a large part of which is consumed by the industrial sector. Mitigating these problems and provision of energy security calls for adopting clean and renewable energy effectively and extensively. According to the U.S. Energy Information Administration [2], the industrial sector consumed 52% of global delivered energy in 2010, and its energy consumption grows by an average of 1.4% per year. In Nigeria this sector’s growth suffers due to insufficient power generation and supply [3] which in turn increases running cost and hampers growth of industries.

Textile industries consumes a large portion of delivered energy use in the sector; over 25% of the delivered electricity use of non-energy intensive manufacturing industries is consumed by textile factories [4]. Indigenous textile factories are experiencing high operational cost due to high cost of electricity with factories spending over 150 million naira in energy bills from the grid and another 60 million on diesel. These factories extensive envelopes remain unexploited and latent even as various available technologies and strategies exist to produce cost-effective energy solutions.

Nigeria lies within a high sunshine belt and thus has enormous solar energy potentials. Integrating solar PV into the building envelope of Nigeria’s textile industrial buildings to harness this solar energy potential would provide valuable clean energy and diversify the energy supply mix.

Compared to large scale power plants located far away from cities, BIPV systems would not require additional land or built structure and is more valuable as it eliminates transmission loss. It has been demonstrated in studies that one unit of on-site renewable energy is around three times the value on energy produced from remote sources [5]. Also, renewable energy integration could have social consequences, encouraging businesses to conserve energy, since its production and performance can be gauged and understood on a micro scale [6].

Architectural integration of solar photovoltaic is the result of a controlled and coherent integration of the solar PV simultaneously from all points of view, functional, constructive and formal (aesthetic) [7].

Building-Integrated Photovoltaics (BIPV) are dual-purpose PV systems, they serve as both the outer layer of a structure and generate electricity for on-site use or export to the grid. BIPV systems can provide savings in materials and electricity costs, reduce pollution, and add to the architectural appeal of a building. The greatest value for BIPV systems is realized by including them in the initial building design [8].

20.1.1 Aim

To provide a design framework for optimizing building form for architectural integration of Building-Integrated Photovoltaic (BIPV) in the design of a textile factory.

20.1.2 Objectives

-

1.

To assess the integration potential of BIPV in the building

-

Envelope of existing textile factories in northern Nigeria.

-

-

2.

To optimize the energy yield from BIPV through optimized building

-

Form in textile factories.

-

20.2 Methodology

The research is an evaluative research, due to its aim, objectives and the nature of data acquisition and analysis. The research uses the case study approach. The cases selected for this study are:

-

1.

Funtua Textiles Limited (FTL ), Funtua, Katsina.

-

2.

United Nigerian Textile PLC (UNTL ), Kaduna.

-

3.

Kaduna Textiles Limited (KTL ), Kaduna.

Tools for data collection and analysis include visual survey, physical measurement, interview and simulation The variables considered in this research are design dependent variables which are required in the integration of BIPV in the building envelope of selected cases and design considerations required for optimum performance of PV systems. They include:

Integration | Variable | Data analysis | |

|---|---|---|---|

Potential of BIPV variables | Roof type | Descriptive analysis | |

Façade type | |||

External building features | |||

Orientation of Buildings | |||

Optimizing BIPV performance variables | Building Form | Simulation | |

Surface tilt | |||

Local climate | Modelling information | ||

Building size | |||

Self-shading | |||

Site features | |||

20.3 Results and Discussion

This section assesses the renewable energy potential of BIPV in Katsina state. It attempts to draw out building forms of textile industries in northern Nigeria and the integration potential of BIPV through examining existing cases and simulating against varying design parameters. It highlights ways to achieve optimum energy yield from integrated photovoltaic systems.

Three cases were visited and studied, which are Funtua Textile Limited (FTL ), Funtua, Katsina, United Nigerian Textiles Plc, Kaduna and Kaduna Textile Limited (KTL ), Kaduna. These cases were selected based on their functions and climatic zones.

The results obtained are presented below under the following headings based on the objectives of the study:

-

1.

Integration potential of BIPV in the building envelope.

-

2.

Optimizing BIPV performance.

20.4 Integration Potential of BIPV in the Building Envelope

The results and assessment of the variables under this objective for each case studied are (Plate 20.1):

In United Nigeria Textile, the roof types found are gable roof and shed roof. Long span corrugated aluminium roofing sheets are used in all cases; illustrations would be used to represent the roof as camera wasn’t allowed into the complex (Plate 20.2).

In Kaduna Textiles Limited, the roof types found are gable roof and saw-tooth roof. The saw-tooth roof covers the spinning and weaving department while the gable roof covers the administrative, engineering and finishing department (Plate 20.3).

20.4.1 Façade Type

Façade type of a building could vary widely; this could depend on the building type, location, architect’s preference or need based on other factors. The façade type could determine the type or even the possibility of BIPV integration.

In Funtua Textiles Limited, the walls are constructed with hollow sandcrete blocks with the upper portion cladded with long span corrugated aluminium sheets. This façade type can be integrated with BIPV systems (Plate 20.4).

In United Nigeria Textile, the factory building’s walls here are majorly constructed with hollow sandcrete block and a few are cladded with long span corrugated aluminium sheets making it possible to be integrated with BIPV systems. Images are not available as camera was disallowed into the premise.

In Kaduna Textiles Limited, the walls of the buildings at the Kaduna Textile Limited are constructed with hollow sandcrete block, solid stone and the upper portion of some buildings cladded with long span corrugated aluminium sheets. The sandcrete area and area cladded with aluminium sheets can be integrated with BIPV. The stone façade used widely for the material aesthetic appeal would lose this appeal but still serve its thermal insulation purpose if integrated with BIPV.

-

Roof type.

-

Façade type.

-

External building features.

20.4.2 Roof Type

The roof surface is among the most important features of a building for the integration of solar BIPV. The type of roof to a large extent determines the potential for BIPV integration in a building.

In Funtua Textiles Limited, the roof types are gable roof, gable with monitor roof and lean-to/shed roof. The lean-to roof covers the engineering department while the monitor roof covers the ginnery and dyeing and finishing department with the remaining building covered with gable roof. Long span aluminium roofing sheets were used in covering these roofs (Plate 20.5).

20.4.3 External Building Elements

This could include shading devices, balconies, parking structures or any external structure supporting the main structure. They provide additional surfaces for integration of BIPV in industrial facilities.

In Funtua Textiles Limited, the Factory buildings has little external devices, consists majorly of plain facades. External device found on site is a covered vehicular parking, an external building element with integration potential (Plate 20.6).

In United Nigeria Textile, the complex has no external device present, presenting no external surface for BIPV integration.

In Kaduna Textiles Limited, the factory buildings have external devices, consists majorly of plain facades. External device found on site is a covered vehicular parking which is an external element with integration potential (Plate 20.7).

20.4.4 Integration Potential of BIPV

The results obtained from the case studies shows that five building envelope components of the six building envelope components considered for this study are present within the case studies with the possibility of BIPV integration.

Building envelope component | Funtua Textiles Limited (FTL) | United Nigeria Textiles (UNTL) | Kaduna Textiles Limited (KTL) |

|---|---|---|---|

Tilted roof | + | + | + |

Flat roof | − | − | − |

Skylight | + | − | + |

Façade walls | + | + | + |

Façade glazing | + | + | + |

External device | + | − | + |

The absence of flat roof for integration is observed throughout the cases studied. With the possibility to integrate BIPV in the Façade walls and tilted roof of the factories in all instances. Skylight is present in both FTL and KTL, with that of KTL north facing making it an inefficient choice for integration. Façade glazing adequate for BIPV is found solely at KTL, the lack of façade glazing is as a result of the need to control internal conditions of the factory to a given humidity and temperature level.

20.5 Optimizing BIPV Performance

The results and assessment of the variables and modelling characteristics studied for each case are:

-

Local climate

-

Building size

-

Site features

-

Building form

-

Building orientation

-

Surface tilt

20.5.1 Local Climate

The irradiation values for the local climates were gotten from PVGIS-CMSAF solar radiation database. The rainfall duration and cloud cover values would be determined from existing literature.

In Funtua Textiles Limited, there is more rainfall during the summers than the winter. It receives an average of 5970 Wh/m2 per day of irradiation on the horizontal plane. The average annual temperature in Funtua is 24.8 °C and about 1024 mm of precipitation falls annually.

In United Nigeria Textile, the local climate is tropical dry having more rainfall during the summers than the winter. This also goes for Kaduna Textiles Limited as they fall within the same local climate. They receive an average of 5770 Wh/m2 per day of irradiation on the horizontal plane (Figs. 20.1, 20.2, 20.3 and 20.4).

Case studies | Solar irradiation | Annual mean temperature | Precipitation |

|---|---|---|---|

Funtua Textiles Limited | 5970 Wh/m2 | 24.8 °C | 1024 mm |

United Nigeria Textile | 5770 Wh/m2 | 25.2 °C | 1211 mm |

Kaduna Textile Limited | 5770 Wh/m2 | 25.2 °C | 1211 mm |

Precipitation, mean temperature and wind speed data for Kaduna. Source: (Meteoblue Fig. 20.4: Cloud cover data for Kaduna. Source: (Meteoblue, 2017)

20.5.2 Site Features

These include soft and hard landscape and could include natural features of the site. They could be of positive impact or negative impact to the solar power generation potential depending on how they relate to the building on site. Their presence could be detrimental when they shade surfaces integrated with BIPV. The site features as observed in the cases studied are discussed.

In Funtua Textiles Limited, the site is laid in an L-shaped pattern with buildings along this path with the surrounding covered in hard and soft landscape. The drive-way and loading bays are finished in concrete with flowers, shrubs and short trees along the sides. Large trees are planted along the east end of the site and in green pockets between the weaving and dyeing department. The trees are positioned at a distance from the building which ensures no shading on building surfaces.

In United Nigeria Textile, buildings are arranged around a central concrete paved yard serving as parking and loading bay with trees heavily scattered around the site. This shades the façade area extensively during the morning and evening period.

In Kaduna Textiles Limited, the site rekindles a trapezium with buildings placed adjacent one another. The access route and loading bays are finished in concrete with few trees within the site and scattered flowers and shrubs around. The administrative area has closely planted trees shading a portion of it during the day, with the trees around the production facility at a distance its shadow falls away from the building.

20.5.3 Building Size

The larger the size of solar PV exposed to the sun the larger the electricity production, given larger buildings a higher potential for electricity generation using solar BIPV. For comparable results all building forms would be assumed to have the same floor area of 1 m2 each and the same wall height of 1 m each.

20.5.4 Building Form

The building forms of the textile factories would be categorized based on their plan layout, roof type.

In Funtua Textiles Limited, the buildings have rectangular plans with individual total floor area ranging from 13500 m2 to 860 m2 in size and a height of about 4 m for the shortest point and 11 m for highest point. The buildings have tilted roofs, the roof types consist of gable roof, monitor roof and lean-to roof.

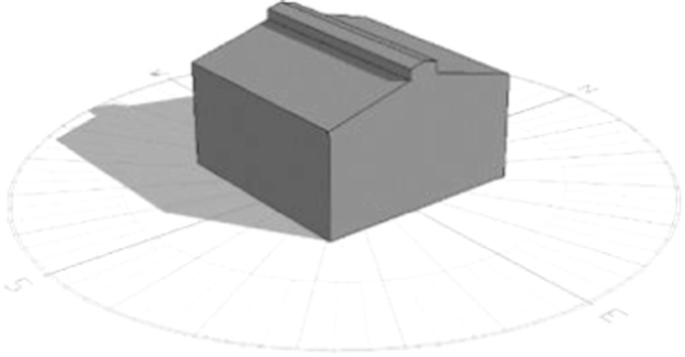

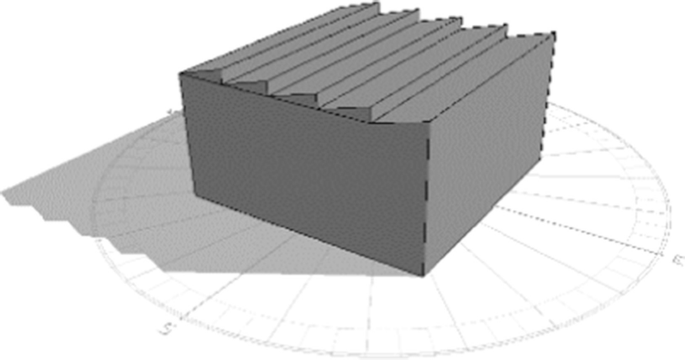

In United Nigeria Textile, the buildings have rectangular plans with heights reaching 10 m at highest point for the weaving and spinning department while the finishing department reaches 6 m (highest point). The buildings are roofed with gable roof and lean-to/shed roof. Illustrations are used to represent these as taking of images within the premises was disallowed (Plate 20.8).

In United Nigeria Textile, the buildings have rectangular plans with heights reaching 10 m at highest point for the weaving and spinning department while the finishing department reaches 6 m (highest point). The buildings are roofed with gable roof and lean-to/shed roof. Illustrations are used to represent these as taking of images within the premises was disallowed (Fig. 20.5).

In Kaduna Textiles Limited, the factory buildings have rectangular plans with the spinning department roofed with a saw-tooth roof while the weaving and finishing departments are roofed with gable roof (Plates 20.9 and 20.10).

Other plan layouts common to industrial buildings would be included in the study and analysed to determine self-shading factor and size available for integration. The plan layouts include:

-

Linear layout

-

L-shape layout

-

U-shape layout

20.5.5 Summary

This section summarizes the building forms established in the cases studied categorized based on their floor plans and roof type. Four categories are established:

-

1.

Rectangular plan with gable roof

-

2.

Rectangular plan with lean-to roof

-

3.

Rectangular plan with monitor roof

-

4.

Rectangular plan with saw-tooth roof

20.5.6 Self-Shading Factor

Even Partial shading can cause significant efficiency losses in BIPV module output. Considering this, a shadow range analysis is carried out on the different roof types of textile industries using Autodesk® Ecotect® Analysis software to determine areas of self-shading.

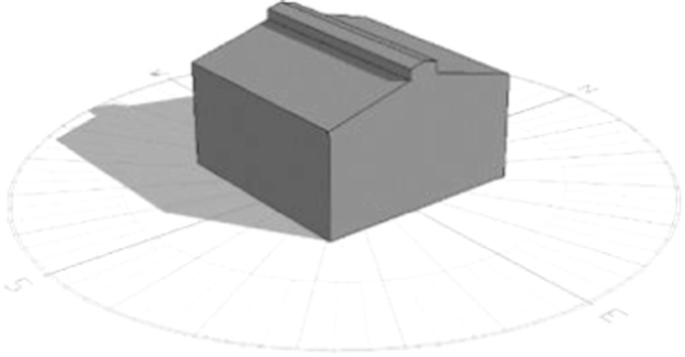

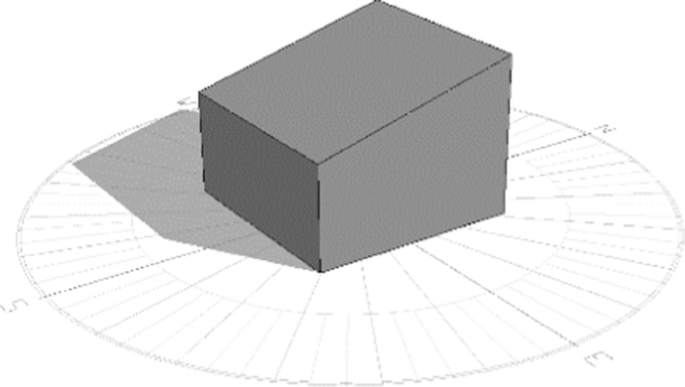

20.5.6.1 Gable Roof

From the above figure the entire northern side of a ‘rectangular plan and gable roofed’ building is observed to be covered in shadows, with no area of the building envelope being self-shaded (Fig. 20.6).

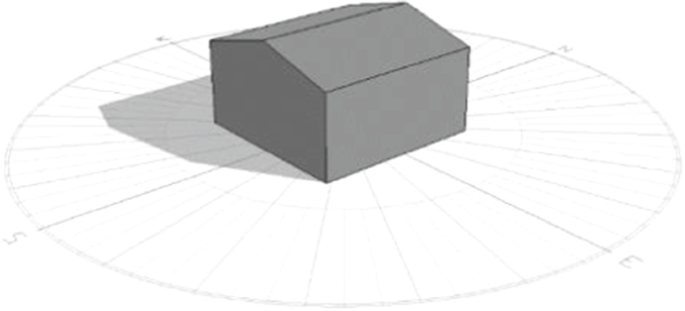

20.5.6.2 Lean-to/Shed Roof

Result from shadow range analysis for a ‘rectangular plan with lean-to roof’ building shows the entire northern side of the building covered in shadows, with no area of the building envelope self-shaded (Fig. 20.7).

20.5.6.3 Monitor Roof

From the above figure the entire northern side of a ‘rectangular plan and monitor roofed’ building is observed to be covered in shadows, with about 19% of the northern roof self-shaded during the months of November through December, January to February and over 11% self-shaded in the months of March and October. While up to 6% of the southern roof gets shaded in the months of June and July with no self-shading during the months of April and September (Fig. 20.8).

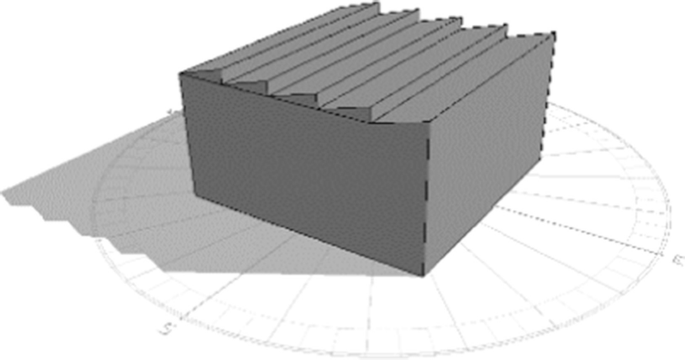

20.5.6.4 Saw-Tooth Roof

From the above figure the entire northern side of a ‘rectangular plan and monitor roofed’ building is observed to be covered in shadows, with about 19% of the northern roof self-shaded during the months of November through December, January to February and over 11% self-shaded in the months of March and October. While up to 6% of the southern roof gets shaded in the months of June and July with no self-shading during the months of April and September (Fig. 20.9).

From the above figure the entire northern side of a ‘rectangular plan and saw-toothed roofed’ building is observed to be covered in shadows, with about 25% of the northern roof self-shaded during the months of November through to February, over 13% is self-shaded in the months of March, October and no shading during the months of April, June, July and September.

20.5.7 Building Form Performance

Based on the results obtained from the shadow analysis carried out on the established building roof types which are gable roof, lean-to roof, monitor roof and saw-tooth roof, lean-to and gable roofs perform better with no self-shading, while monitor roof performs better than the scissor-tooth roof having about 19%, 11% and 6% shaded during the months of November to February, March/October and June/July, respectively. While scissor-tooth roof has about 25%, 13% and 8% of its surface shaded during the months of November to February, March/October and June/July, respectively.

Building forms | Orientation | Self-shading | Generation potential |

|---|---|---|---|

| 100% of roof surface facing south | No Self-shading | 47.40 kWh |

| Only 50% of roof surface faces south 50% faces north | No Self-shading | 45.15 kWh |

| Only 50% of roof surface faces south 50% faces north | • 16% shaded November • 9% shaded March • 5% shaded July | 39.80 kWh |

| 100% of roof surface facing south | • 25% shaded November • 15% shaded March • 9% shaded July | 37.92 kWh |

20.5.8 Orientation

Orienting the building so the longer side or side with the largest area faces the orientation with highest energy potential is key. A simulation analysis is carried out to determine this orientation. The simulations test for the solar energy potential for surfaces facing North, South, East and West, respectively, and for the exact azimuth that gives the highest potential.

20.5.8.1 Simulation Results

The energy potential of the BIPV systems is tested at four different orientations (East, West, South and North). A crystalline silicon cell is used with an assumed efficiency of 15% (average commercial efficiency). The simulation analysis was conducted using PVGis® tool by Joint Research Center (JRC ).

Assumptions while carrying out tests are:

-

Nominal power of BIPV system: 1.0 kW

-

Efficiency of BIPV cell: 15%

-

Losses (cables, inverters): 14%

-

Surface area of BIPV system: 1m2

-

Tilt angle of BIPV system: 15°

The results/performance are presented in graphical charts below:

The figure above represents crystalline silicon cell performance when placed facing four different orientations (East, South, West and North). It performs best when faced due south producing an average of 18.95 kWh/m2 of electricity each month (Fig. 20.10).

20.5.9 Tilt Angle

BIPV performance for different tilt angles at different orientations would be studied. This would be used to define the angles at which the building surfaces would be tilted. Documentation would be made on this and the simulation analysis result presented for each respective tilt angle to show performances.

20.5.9.1 Simulation Results

The energy potential of the BIPV systems are tested at varying tilt angles for each of the four orientations (East, West, South and North). A crystalline silicon cell is used with an assumed efficiency of 15% (average commercial efficiency). The simulation analysis is conducted using PVGis® tool by Joint Research Center (JRC ).

Assumptions while carrying out tests are:

-

Nominal power of BIPV system: 1.0 kW

-

Efficiency of BIPV cell: 15%

-

Losses (cables, inverters): 14%

-

Surface area of BIPV: 1m2

The results/performance are presented below:

The figure above compares the mean monthly electricity production of commercial crystalline silicon cells at various tilt angles when placed facing due south, west, north and east, respectively. It could be observed that the cells, when placed due south, perform best at all tilt angles. The peak electricity production of 18.95 kWh/m2 occurs when the cells are placed due south and tilted at 16°.

The results shows that a square metre of BIPV cells when faced south would produce up to 18.95 kWh of electricity when tilted at 16° which is optimal for this orientation, this value varies with varying tilt angle as shown in Fig. 20.11. At 90° it produces 9.5 kWh of electricity.

A west facing crystalline silicon BIPV cell as shown in Fig. 20.11 produces up to 17.55 kWh/m2 of electricity tilted at 15° and 8.5 kWh/m2 tilted at 90°.

From Fig. 20.11 it can be observed that a north facing crystalline silicon BIPV cell produces 17.16 kWh/m2 of electricity when tilted at 15° and 4.24 kWh/m2 tilted at 90°.

A crystalline silicon BIPV cell oriented due east as shown in Fig. 20.11 produces 17.75 kWh/m2 of electricity at a 15° tilt and 8.91 kWh/m2 when tilted at 90°. The production when placed facing south is 1.2 kWh/m2 better than when oriented due east, 1.4 kWh/m2 better than when oriented due east and 1.79 kWh/m2 better than when oriented due north.

The results show that optimum electricity for crystalline silicon BIPV cells is generated at a module tilt angle of 16° and a module orientation of −4° having the potential to generate an average of 18.95 kWh/m2 of electricity monthly.

20.6 Summary of Findings

-

The results show that solar photovoltaic systems could be integrated into the tilted roof, skylight, façade walls, façade glazing and external device of the factory’s building envelope.

-

Rectangular plans with gable, monitor, lean-to and scissor-tooth roofs are the building forms predominantly used for textile factories in tropical dry climates.

-

Crystalline silicon cell has the potential to generate an average monthly of 18.95 kWh/m2 of electricity.

-

Optimum electricity is generated when modules are placed on surfaces with a tilt angle of 16° and an orientation of −4° (South −0°).

-

Lean-to roof with rectangular plan performs best with no self-shading and provides the largest surface for BIPV integration (Fig. 20.12).

References

Oyedepo SO (2012) Energy and sustainable development in Nigeria: the way forward. Energy Sustain Soc 2:15

U.S. Energy Information Administration (2013) International energy outlook 2013. U.S. Energy Information Administration, Washington, DC

Ibikunle TS (2014) Problems crippling manufacturing in Nigeria. In: Ibikunle TS IPWA Plc MD, Vanguard

Energy Information Administration (EIA) (2013) Electricity use by machine drives varies significantly by manufacturing industry. U.S Energy Information Administration, Washington, DC

Allen SR, Hammond GP (2008) Energy analysis and environmental life cycle assessment of a micro-wind turbine. J Power Energy 222(A7):669–684

Lazarus N (2009) A practical guide to producing affordable carbon neutral developments. BioRegional Development Group

International Energy Agency (2013) Report T.41.A.3/2: IEA SHC task 41 designing photovoltaic systems for architectural integration. SHC Programme

European Photovoltaic Technology Platform (2007) Building integrated photovoltaics: a new design opportunity for architects. European SUNRISE Project

Aaditya G, Mani M (2013) Climate-responsive integrability of building-integrated photovoltaics. Int J Low Carbon Technol 8(4):271–281

International Renewable Energy Agency (IRENA) (2012) Solar photovoltaics. Renewable energy technologies: cost analysis series, Volume 1: Power Sector (4/5)

Uzoma CC, Nnaji CE, Ibeto CN, Okpara CG, Nwoke OO, Obi IO et al (2011) Renewable energy penetration in Nigeria: a study of the south-east zone. Continental J Environ Sci 5(1):1–5

Waseef A (2014) Tilt and orientation: a preference factor among photovoltaic roof systems. Int J Innov Res Sci Eng Technol 3(3):10750–10758

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Batagarawa, A., Abdulkarim, Y.A., Sagada, M.L. (2020). Optimizing Building Form for Integration of Solar Photovoltaic in the Design of a Textile Industry in Katsina, Nigeria. In: Sayigh, A. (eds) Renewable Energy and Sustainable Buildings. Innovative Renewable Energy. Springer, Cham. https://doi.org/10.1007/978-3-030-18488-9_20

Download citation

DOI: https://doi.org/10.1007/978-3-030-18488-9_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-18487-2

Online ISBN: 978-3-030-18488-9

eBook Packages: EnergyEnergy (R0)