Abstract

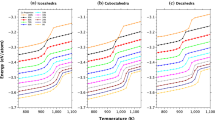

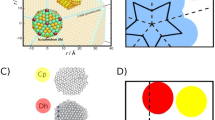

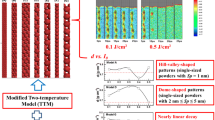

The effect of cooling rate on the microstructure evolution of liquid Cu nanoparticles during their solidification process is investigated by using a molecular dynamics simulation based on the embedded atom method (EAM) potential developed by Foiles et al.. The potential energy analysis, the pair distribution function and the common neighbor analysis have been used. The results show that the solidification point increases with decreasing cooling rate and that the solidification of the microstructure of Cu nanoparticles varies with the cooling rate. The microstructure consists of fcc, hcp and bcc crystals or mixtures, though the fcc structure dominates, except in the amorphous state. An amorphous structure was obtained when the cooling rate reached 1.0 × 1013 K/s or higher while crystallization degree increased with decreasing cooling rate, and the total content of crystal structures reached to 95% when the cooling rate dropped to 4.0 × 1011 K/s, which was nearly a perfect crystal structure. The results also indicate that a single-crystal nanoparticle will not be obtained by quenching the liquid metal under various cooling rates.

Similar content being viewed by others

References

K. Nishimura and N. Miyazaki, Comput. Mater. Sci. 31, 269 (2004).

X. G. Zeng, S. S. Xu, H. Y. Chen and J. L. Li, Trans. Nonferrous Met. Soc. China 20, S519 (2010).

Z. W. Cui, Y. Sun and J. M. Qu, Solid State Ionics 226, 24 (2012).

Z. W. Cui, F. Gao, Z. H. Cui and J.M. Qu, J. Power Sour. 207, 150 (2012).

K. Y. Chen, H. B. Liu, X. P. Li, Q. Y. Han and Z. Q. Hu, J. Phys.: Condens Matter 7, 2379 (1995).

Q. Yue, C. Tahir, K. Yoshitakes and W. A. Goddard, Phys. Rev. B 59, 3527 (1999).

C. S. Liu, Z. G. Zhu, J. C. Xia and D. Y. Sun, Chinese Phys. Lett. 17, 34 (2000).

H. Li, G. H. Wang, X. F. Blan and F. Ding, Phys. Rev. B 65, 035411 (2003).

K. J. Dong, R. S. Liu, A. B. Yu, R. P. Zou and J. Y. Li, J. Phys.: Condens Matter 15, 743 (2003).

G. R. Zhou and Q. M. GAO, Solid state commun. 136, (32) 2005.

F. Li, X. J. Liu, H. Y. Hou, G. Chen and G. L. Chen, Intermetallics 19, 630 (2011).

Y. Shibuta and T. Suzuki, Chem.Phys. Lett. 502, 82 (2011).

L. Wang, X. F. Bian and H. Li, Chinese J. Chem. Phys. 13, 544 (2000).

C. S. Liu, J. Xia, Z. G. Zhu and D. Y. Sun, J. Chem. Phys. 114, 7506 (2001).

T. Zhang, X. R. Zhan, G. Guan, Y. H. Qi and C. Y. XU, Acta Metal. Sin. 40, 251 (2004).

X. H. Yi, R. S. Liu, Z. A. Tian, Z. Y. Hou, X. Y. Li and Q. Y. Zhou, Trans. Nonferrous Met. Soc. China 18, 33 (2008).

H. Pang, Z. H. Jin and K. Lu, Phys. Rev. B 67, 0941131 (2003).

F. F. Chen, H. F. Zhang, F. X. Qin and Z. Q. Hu, J. Chem. Phys. 120, 1826 (2004).

T. Zhang, X. R. Zhang and S. L. Ding, Chinese J. At. Mol. Phys. 20, 357 (2003).

S. M. Foiles, M. Baskes and M. S. Daw, Phys. Rev. B 33, 7983 (1986).

S. J. Plimpton, J. Comp. Phys. 117, 1 (1995).

Information on http://lammps.sandia.gov.

Hoover, Phys. Rev. A 31, 1695 (1985).

Hoover, Phys. Rev. A 34, 499 (1986).

M. P. Allen and D. J. Tildesley, Computer simulation of liquids (Oxford University Press, Oxford, 1987).

Y. Waseda, The structure of non-crystalline materials (McGraw-Hill, New York, 1980).

W. Jin, R. K. Kalla, P. Vashishta and J. P. Rino, Phys. Rev. B 50, 118 (1994).

Y. Waseda, The Structure of Non-Crystalline Materials, Liquid, and Amorphous (McGraw-Hill, New York, 1980).

J. D. Honeycutt and H. C. Andersen, J.Phys. Chem. 91, 4950 (1987).

H. Tuzuki, P. S. Branicio and J. P. Rino, Comput. Phys. Commun. 177, 518 (2007).

D. Faken, H. Jonsson, Comput. Mater. Sci. 2, 279 (1994).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, YQ., Zeng, XG., Chen, HY. et al. Molecular dynamics simulation on microstructure evolution during solidification of copper nanoparticles. Journal of the Korean Physical Society 62, 1645–1651 (2013). https://doi.org/10.3938/jkps.62.1645

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.62.1645