Abstract

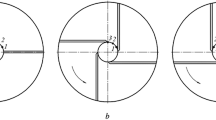

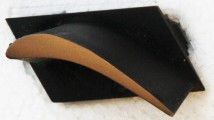

A combined model for calculation of abrasive wear intensity of rotor-accelerator blades in a centrifugal mill is proposed. It involves defining the impact velocity and the attack angle of the particles, calculating the impact-abrasive wear, defining the velocity of the particle along the blade, and calculating the wear under abrading effect. It was stated that the wear under abrasion is by 1.5 times lower than under impact. A good agreement of calculation results with experimental data confirms the adequacy of the combined model.

Similar content being viewed by others

REFERENCES

Barokha, E.L., Vorob’ev, V.V., and Gorobets, A.V., Centrifugal crushers and impact mills, Materialy 3-i mezhdunarodnoi nauchno-tekhnicheskoi konferentsii “Tsentrobezhnaya tekhnika—vysokie tekhnologii” (Proc. Third Int. Sci.-Tech. Conf. “Centrifugal Equipment—High Tehcnologies”), Minsk: NPO Tsentr, 2008, pp. 5–15.

Tabolich, A.V. and Bondarenko, S.N., Construction capacities to improve wear resistance of accelerators of centrifugal-impact mills, Gorn. Mekh. Mashinostr., 2016, no. 2, pp. 71–77.

Vaitekhovich, P.E., Grebenchuk, P.S., Tabolich, A.V., and Verkhovodka, A.A., Effect of rotor design on the speed of grinded material in centrifugal impact crushers, Gorn. Mekh. Mashinostr., 2017, no. 2, pp. 54–63.

Kragel’skii, I.V., Trenie i iznos (Friction and Wear), Moscow: Mashinostroenie, 1968.

Laguna-Camacho, J.R., Vite-Torres, M., Gallardo-Hernández, E.A., and Vera-Cárdenas, E.E., Solid particle erosion on different metallic materials, in Tribology in Engineering, Pihtili, H., Ed., London: InTech, 2013, ch. 5, pp. 63–78.

Chen, H., Zhao, D., Wang, Q., Qiang, Y., and Qi, J., Effects of impact energy on the wear resistance and work hardening mechanism of medium manganese austenitic steel, Friction, 2017, vol. 5, no. 4, 447–454.

Meng, H.C. and Ludema, K.C., Wear models and predictive equations: their form and content, Wear, 1995, vols. 181–183, pp. 443–457.

Beckmann, G. and Gotzmann, I., Analytical model of the blast wear intensity of metals based on a general arrangement for abrasive wear, Wear, 1981, vol. 73, pp. 325–353.

Soldatenkov, I.A., Mezrin, A.M., and Sachek, B.Ya., Implementation of a wear model of rigid bodies for identifying the wear law based on the results of tribological tests, J. Frict. Wear, 2015, vol. 36, no. 6, pp. 528–533.

Khan, Z.A. Chacko, V., and Nasir, H., A review of friction models in interacting joints for durability design, Friction, 2017, vol. 5, no. 1, 1–22.

Ding, C., Zhu, H., Sun, G., Zhou, Y., and Zou, X., Chaotic characteristics and attractor evolution of friction noise during friction process, Friction, 2017, vol. 6, no. 1, 47–61.

Khodakov, G.S., Abrasive grinding of glass, Opt.-Mekh. Prom-st, 1985, no. 5, pp. 31–36.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Kromin

About this article

Cite this article

Vaitekhovich, P.E. Combined Model of Abrasive Wear of Rotor-Accelerator Blades in a Centrifugal Mill. J. Frict. Wear 39, 444–450 (2018). https://doi.org/10.3103/S1068366618060156

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366618060156