Abstract

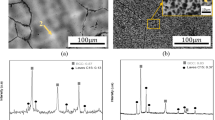

The influence of alloying TiC0.5N0.5 carbonitride by transition metals of Group V (V, Nb, and Ta) on the contact interaction mechanism with the Ni–25%Mo melt (T = 1450°C, τ = 1 h, rarefaction is 5 × 10–2 Pa) is systematically studied by X-ray spectral microanalysis and scanning electron microscopy for the first time. It is established that the dissolution of single-type Ti1 –n\({\text{Me}}_{n}^{{\text{V}}}\)C0.5N0.5 carbonitrides (n = 0.05) is an incongruent process (alloying metal and carbon preferentially transfer into the melt), and the relative rate and degree of incongruence of the dissolution process of carbonitrides in a series of alloying metals V–Nb–Ta vary nonmonotonically. An explanation for the discovered effects is proposed. The causal-effect relation between the initial composition of Ti0.95\({\text{Me}}_{{0.05}}^{{\text{V}}}\)C0.5N0.5 carbonitride (the grade of the alloying metal) and composition of the Ti1 – n – mMon\({\text{Me}}_{m}^{{\text{V}}}\)Cx K-phase that is precipitated from the melt upon system cooling is analyzed. It is shown that the factor determining the composition of the forming K-phase is the ΔT factor (the degree of exceeding crystallization temperatures of carbide eutectics Ni/MeVC over the crystallization temperature of the Ni/Mo2C eutectic that is the lowest melting in these systems). The conclusion is argued that the interrelation between the initial carbonitride composition and the composition of the K-phase is a consequence of a microinhomogeneous structure of metallic alloys. It is shown that this interrelation is rather common and manifests itself in all studied systems irrespective of the type of alloying Group V metal and presence or absence of molybdenum in the melt.

Similar content being viewed by others

REFERENCES

Clark, E.B. and Roebuck, B., Extending the application areas for titanium carbonitride cermets, Int. J. Refract. Metal. Hard Mater., 1992, vol. 11, pp. 23–33.

Ettmayer, P., Kolaska, H., Lengauer, W., and Dreyer, K., Ti(C, N) cermets—metallurgy and Properties, Int. J. Refract. Metal. Hard Mater., 1995, vol. 13, pp. 343–351.

Zhang, S., Material development of titanium carbonitride-based cermets for machining application, Key Eng. Mater., 1998, vol. 138–140, pp. 521–543.

Xiao, J.H., Xiong, W.H., Lin, S.J., Qu, J., and Zhou, M., Review on the preparation and application of Ti(C,N)-based cermet composite, Mater. Rev., 2010, vol. 24, pp. 21–27.

Peng, Y., Miao, H., and Peng, Z., Development of TiCN-based cermets: Mechanical properties and wear mechanism, Int. J. Refract. Met. Hard Mater., 2013, vol. 39, pp. 78–89.

Kang, S., Cermets. in: Comprehensive Hard Materials, Sarin, V.K., Ed., UK: Elsevier, 2014, vol. 1, pp. 139–181.

Rajabi, A., Ghazali, M.J., and Daud, A.R., Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermets: A review, J. Mater. Design, 2015, vol. 67, pp. 95–106.

Zhilyaev, V.A., Patrakov, E.I., and Shveikin, G.P., Current status and potential for development of W-free hard alloys, in: Proc. 2nd Int. Conf. Sci. Hard Mater., (Rhodes, Greece, 1984), Bristol, Boston: Hilger, 1986, pp. 1063–1073.

Lindahl, P., Mainer, T., and Jonsson, H., Microstructure and mechanical properties of a (Ti, W, Ta, Mo) (C, N)–(Co, Ni) type cermet, Int. J. Refract. Met. Hard Mater., 1993, vol. 4, pp. 187–204.

Zhang, S., Qin, C.D., and Lim, L.C., Solid solution extent of WC and TaC in Ti(C, N) as revealed by lattice parameter increase, Int. J. Refract. Met. Hard Mater., 1993–1994, vol. 12, pp. 329–333.

Park, S. and Kang, S., Toughened ultrafine (Ti, W)(CN)–Ni cermets, Scripta Mater., 2005, vol. 53, pp. 129–133.

Kim, S.W., Ahn, S., and Kang, S., Effect of the complete solidsolution phase on the microstructure of Ti(CN)-based cermets, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, pp. 224–228.

Liu, Y., Jin, Y., Yu, H., and Ye, J., Ultrafine (Ti, M)(C, N)-based cermets with optimal mechanical properties, Int. J. Refract. Met. Hard Mater., 2011, vol. 29, pp. 104–107.

Chen, X., Xiong, W., Yang, Q., Yao, Z., and Huang, Y., Microstructure and mechanical properties of (Ti, W, Ta)C-xMo–Ni cermets, Int. J. Refract. Met. Hard Mater., 2012, vol. 31, pp. 56–61.

Chicardi, E., Torres, Y., Hvizdos, P., and Gotor, F.J., Effect of tantalum content on the microstructure and mechanical behavior of cermets based on (TixTa1 – x)(C0.5N0.5) solid solutions, Mater. Design, 2014, vol. 53, pp. 435–444.

Zhilyaev, V.A., Solid-solution nature of refractory interstitial phases. Part I. Physical substantiation, Materialovedenie, 2012, no. 3, pp. 3–9.

Zhilyaev, V.A., Solid-solution nature of refractory interstitial phases. Part II. Physical substantiation, Materialovedenie, 2012, no. 4, pp. 3–12.

Zhilyaev, V.A., Interrelation of the composition, structure and properties of refractory interstitial phases, in: G.V. Samsonov—uchenyi, uchitel’, drug (G.V. Samsonov—a Scientist, Teacher, and Friend), Kislyi, P.S., Ed., Kiev: Naukova Dumka, 2012, pp. 167–180.

Zhilyaev, V.A. and Patrakov, E.I., Influence of alloying of TiC0.5N0.5 carbonitride by zirconium on the interaction mechanism with the Ni–Mo melt, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2016, no. 3, pp. 31–42.

Zhilyaev, V.A. and Patrakov, E.I., Kinetics and mechanism of the contact interaction of titanium carbonitride with Ni–Mo-melt, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2015, no. 2, pp. 30–37.

Zhilyaev, V.A., Powder materials based on refractory interstitial phases, Doctoral (Eng.) Dissertation, Perm’: Perm’ Gos. Tekh. Univ., 2010.

Serezhkin, V.N. and Pushkin, D.V., Kristallokhimicheskie radiusy i koordinatsionnye chisla atomov (Crystal Chemical Radii and Coordination Numbers of Atoms), Samara: Univers-Group, 2005.

Baum, B.A., Metallicheskie zhidkosti (Metal Liquids), Moscow: Nauka, 1979.

Gavrilin, I.V., Plavlenie i kristallizatsiya metallov i splavov (Melting and Crystallization of Metals and Alloys), Vladimir: Vladimir. Gos. Univ., 2000.

Zhilyaev, V.A. and Patrakov, E.I., The mechanism of liquid-phase interaction of double carbides (Ti,Me)C with nickel, Konstr. Kompoz. Mater., 2006, no. 4, pp. 199–201.

Diagrammy sostojanija dvojnyh metallicheskih system: Spravochnik (Phase Diagrams of Binary Metallic Systems: Handbook), Lyakishev, N.P., Ed., Moscow: Mashinostroenie, 1996.

Ershov, G.S. and Maiboroda, V.P., Diffuziya v metallurgicheskikh rasplavakh (Diffusion in Metallurgical Melts), Kiev: Naukova Dumka, 1990.

Zhilyaev, V.A. and Patrakov, E.I., Effect of doping by Group IV–VI transition metals of titanium carbonitride on the interaction with the nickel melt, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2014, no. 4, pp. 30–36.

Zhilyaev, V.A. and Patrakov, E.I., Regularities of the contact interaction of (Ti1–n \({\text{Me}}_{n}^{{{\text{IV}}{\text{,V}}}})\)C double carbides with the Ni–Mo melt, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2015, no. 3, pp. 25–35.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Zhilyaev, V.A., Patrakov, E.I. Regularities of Metallurgical Reactions of Ti1 –n\({\text{Me}}_{n}^{{\text{V}}}\)C0.5N0.5 Carbonitrides with the Ni–Mo Melt. Russ. J. Non-ferrous Metals 59, 664–670 (2018). https://doi.org/10.3103/S1067821218060196

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218060196