Abstract

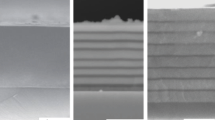

The thermal stability of multilayered nanostructured coatings is evaluated by analyzing the diffusion mobility of layer components. The possibility of increasing the thermal stability of multilayered coatings based on mutually soluble Ti–Al–N and Cr–N layers due to the introduction of an additional barrier layer based on Zr–N into a multilayered nanostructure is investigated in detail. Calculated diffusivities of basic metallic elements of the coating into corresponding nitride layers upon heating in a temperature range of 800–1000°C evidence the absence of noticeable diffusion spread of layer boundaries in the presence of the Zr–N-based barrier layer. For example, their values lower upon its introduction (it is found at t = 1000°C, cm2/s: DCr/TiN = 5 × 10–17, Dcr/ZrN = 2 × 1018, \({D_{Ti/C{r_2}N}}\) = 9 × 10–18, and DTi/ZrN = 3 × 10–18). The physicomechanical properties of coatings do not vary upon their vacuum annealing at t < 900°C; however, they noticeably lower with a further increase in temperature due to the degradation of a multilayered coating structure during annealing.

Similar content being viewed by others

References

Antsiferov V.N., Kameneva A.L., and Pimenova N.V., Study of the structure and formation of nanosized ionplasma Ti–Zr–N, Ti–Al–N, Ti–Zr–O–N, Ti–Al–O–N, and Ti–B–Si–N coatings, in: Tonkie plenki v elektronike: Materialy XIII Mezhdunarodnoi nauchnotekhnicheskoi konferentsii (Thin Films in Electronics: Proc. XIII Int. Scientific and Technical Conf.), Moscow: Mos. Gos. Tekh. Univ., 2007, pp. 328–335.

Antsiferov V.N. and Kameneva A.L., Structure formation (nanostructuring) of films obtained by ion-plasma methods (review). in: Tonkie plenki v elektronike: Materialy XIV Mezhdunarodnoi nauchno-tekhnicheskoi konferentsii (Thin Films in Electronics: Proc. XIV Int. Scientific and Technical Conf.), Moscow: AO TsNITI “Tekhnomash”, 2008, pp. 448–453.

Antsiferov, V.N. and Kosogor, S.P., Phase composition and structure of multilayered nanocrystalline coatings based on titanium carbides and nitrides, Metally, 1997, no. 6, pp. 93–96.

Antsiferov, V.N. and Kameneva, A.L., Experimental study of the structure of Ti–Zr–N-based multicomponent nanostructured coatings formed by ion-plasma methods, Izv. Vyssh. Uchebn. Zaved. Poroshk. Metall. Funkts. Pokryt., 2007, no. 1, pp. 53–61.

Antsiferov, V.N. and Kameneva, A.L., RF Patent 2429311, 2011.

Antsiferov, V.N., Kameneva, A.L., Klochkov, A.Yu., and Novikov, R.S., RF Patent 2361013, 2009.

Nordin, M., Larsson, M., and Hogmark, S., Mechanical and tribological properties of multilayered PVD TiN/CrN, Wear, 1999, vol. 232, no. 2, pp. 221–225, http://www.sciencedirect. com/science/article/pii/S0043164899001490.

Yaomin Zhou, Reo Asaki, We-Hyo Soe, Ryoichi Yamamoto, Rong Chen, and Akira Iwabuchi, Hardness anomaly, plastic deformation work and fretting wear properties of polycrystalline TiN/CrN multilayers, Wear, 1999, vol. 236, pp. 159–164. http://www.sciencedirect.com/science/article/pii/S0043164899002720/.

Zhang, Z.G., Rapaud, O., Allain, N., Mercs, D., Baraket, M., Dong, C., and Coddet, C., Microstructures and tribological properties of CrN/ZrN nanoscale multilayer coatings, Appl. Surf. Sci., 2009, vol. 255, pp. 4020–4026. http://www.sciencedirect.com/science/ar ticle/pii/S0169433208022423.

Hollek, H., Dvoinye i troinye karbidnye i nitridnye sistemy perekhodnykh metallov (Binary and Ternary Transition Metal Nitride Systems), Levinsky, Yu.V., Ed., Moscow, Metallurgiya, 1988.

Barshilia, C. Harish, Jain, Anjana, and Rajam, K.S., Structure, hardness and thermal stability of nanolayered TiN/CrN multilayer coatings, Vacuum, 2004, vol. 72, pp. 241–248, http://www.sciencedirect.com/science/ar ticle/pii/S0042207X03001477.

Kieffer, R. and Ettmayer, P., Recent advances in the knowledge and applications of transition metal nitrides //high temp, High Press., 1974, vol. 6, pp. 253–260.

Zeng, X.T., Zhang, S., Sun, C.Q., and Liu, Y.C., Nanometric-layered CrN/TiN thin films mechanical strength and thermal stability, Thin Solid Films, 2003, vol. 424, pp. 99–102. http://www.sciencedirect.com/science/ar ticle/pii/S0040609002009215.

Blinkov, I.V., Volkhonskii, A.O., Kuznetsov, D.V., and Skryleva, E.A., Investigation of structure and phase formation in multilayer coatings and their thermal stability, J. Alloys Compd., 2014, vol. 586, pp. S381–S386. http://www.sciencedirect.com/science/article/pii/S0925838812021731.

Shelekhov, E.V. and Sviridova, T.A., Programs for X-ray analysis of polycrystals, Met. Sci. Heat Treat., 2000, vol. 42, pp. 309–313. http://link.springer.com/article/10.1007%2FBF02471306.

Hui-Wen Chang, Ping-Kang Huang, Jien-Wei Yeh, Andrew Davison, Chun-Huai Tsau, and Chih-Chao Yang, Influence of substrate bias, deposition temperature and post-deposition annealing on the structure and properties of multi-principal-component (AlCrMoSiTi)N coatings, Surf. Coat. Technol., 2008, vol. 202, pp. 3360–3366. http://www.sciencedirect.com/science/article/pii/S0257897207012650.

Biwer, B.M. and Bernasek, S.L., Electronic spectroscopic study of the iron surface and its interaction with oxygen and nitrogen, J. Electron Spectrosc. Relat. Phenom., 1986, vol. 40, pp. 339–351. http://www.sciencedirect.com/science/article/pii/0368204886800445.

Takano, I., Isobe, S., Sasaki, T.A., and Baba, Y., Nitrogenation of various transition metals by- ion implantation, Appl. Surf. Sci., 1989, vol. 37, pp. 25–32. http://www.sciencedirect.com/science/article/pii/0169433289909707.

Nishimura, O., Yabe, K., and Iwaki, M., X-ray photoelectron spectroscopic studies of high-dose nitrogen ion implanted-chromium: a possibility of a standard material for chemical state analysis, J. Electron. Spectrosc. Relat. Phenom., 1989, vol. 49, pp. 335–342. http://www.sciencedirect. com/science/article/pii/0368204889850212.

Author information

Authors and Affiliations

Corresponding author

Additional information

In memory of the Editor-in-Chief

Original Russian Text © A.O. Volkhonskii, I.V. Blinkov, Yu.V. Levinsky, E.A. Skryleva, 2016, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2016, No. 4, pp. 86–93.

About this article

Cite this article

Volkhonskii, A.O., Blinkov, I.V., Levinsky, Y.V. et al. Evaluation of Thermal Stability of Multilayered Nanostructured Coatings Based on Analysis of Diffusion Mobility of Components of the Layers. Russ. J. Non-ferrous Metals 58, 678–683 (2017). https://doi.org/10.3103/S1067821217060141

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821217060141