Abstract

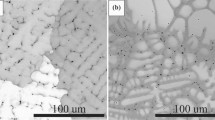

Microstructural features of new master alloys of the Al–Hf–Sc system with metastable aluminides with a cubic lattice identical to the lattice of a matrix of aluminum alloys are investigated using optical microscopy, scanning electron microscopy, and electron probe microanalysis. Binary and ternary alloys are smelted in a coal resistance furnace in graphite crucibles in argon. Alloys Al–0.96 at % Hf (5.98 wt % Hf) and Al–0.59 at % Hf (3.77 wt % Hf) are prepared with overheating above the liquidus temperature of about 200 and 400 K, respectively. Alloys are poured into a bronze mold, the crystallization rate in which is ~103 K/s. Metastable Al3Hf aluminides with a cubic lattice are formed only in the alloy overheated above the liquidus temperature by 400 K. Overheating of ternary alloys, in which metastable aluminides Al n (Hf1–xSc x ) formed, is 240, 270, and 370 K. Depending on the Hf-to-Sc ratio in the alloy, the fraction of hafnium in aluminides Al n (Hf1–xSc x ) varies from 0.46 to 0.71. Master alloys (at %) Al–0.26Hf–0.29Sc and Al–0.11Hf–0.25Sc (wt %: Al–1.70Hf–0.47Sc and Al–0.75Hf–0.42Sc) have a fine grain structure and metastable aluminides of compositions Al n (Hf0.58Sc0.42) and Al n (Hf0.46Sc0.54), respectively. Sizes of aluminides do not exceed 12 and 7 μm. Their lattice mismatch with a matrix of aluminum alloys is smaller than that for Al3Sc. This makes it possible to assume that experimental Al–Hf–Sc master alloys manifest a high modifying effect with their further use. In addition, the substitution of high-cost scandium with hafnium in master alloys can considerably reduce the consumption of the latter.

Similar content being viewed by others

References

Hyde, K.B., Norman, A.F., and Prangnell, P.B., The effect of Ti on grain refinement in Al–Sc alloys, Mater. Sci. Forum, 2002, vols. 396–402, pp. 39–44.

Min, Song., Yuehui, He., and Shanfeng, Fang., Effect of Zr content on the yield strength of an Al–Sc alloys, J. Mater. Eng. Perform, 2011, vol. 20, no. 3, p. 377.

Dalen, M.E., Dunand, D.C., and Seidman, D.N., Effects of Ti additions on the nanostructure and creep properties of precipitation-strengthened Al–Sc alloys, Acta Mater., 2005, vol. 53, no. 15, p. 4225.

Royset, J. and Ryum, N., Scandium in aluminium alloys, Int. Mater. Rev., 2005, vol. 50, no. 1, p. 19.

Zakharov, V.V., Combined alloying of aluminum alloys with scandium and zirconium, Metal. Sci. Heat Treat., 2014, vol. 56, no. 5, pp. 281–286.

Zakharov, V.V., Revisiting alloying aluminum alloys with transition metals, Metalloved. Term. Obrab., 2017, no. 2 (740), pp. 3–8.

Norman, A.F., Prangnell, P.B., and McEwen, R.S., The solidification behavior of dilute aluminium–scandium alloys, Acta Mater., 1998, vol. 46, no. 16, p. 5715.

Marquis, E.A. and Seidman, D.N., Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys, Acta Mater., 2001, vol. 49, pp. 1909–1919.

Fuller, C.B., Murray, J.L., and Seidman, D.N., Temporal evolution of the nanostructure of Al(Sc,Zr) alloys: Part I. Chemical compositions of Al3(Sc1–xZrx) precipitates, Acta Mater., 2005, vol. 53, no. 20, pp. 5401–5413.

Knipling, K.E., Karnesky, R.A., Lee, C.P., Dunand, D.C., and Seidman, D.N., Precipitation evolution in Al–0.1Sc, Al–0.1Zr and Al–0.1Sc–0.1Zr (at %) alloys during isochronal aging, Acta Mater., 2010, vol. 58, pp. 5184–5195.

Carlsson, A.E. and Meschter, P.J., Relative stability of L12, D022, and D023 structures in MAl3 compounds, J. Mater. Res., 1989, vol. 4, no. 5, pp. 1060–1063.

Ghosh, G. and Asta, M., First-principles calculation of structural energetics of Al–TM (TM = Ti, Zr, Hf) intermetallics, Acta Mater., 2005, vol. 53, p. 3225.

Harada, Y. and Dunand, D.C., Microstructure of Al3Sc with ternary transition-metal additions, Mater. Sci. Eng. A, 2002, vol. 329–331, pp. 686–695.

Brodova, I.G., Zamyatin, V.M., Popel, P.S., Esin, V.O., Baum, B.A., Moiseev, A.I., Korshunov, I.P., and Polents, I.V., Formation conditions of metastable phases during the crystallization of Al–Zr alloys, Rasplavy, 1988, vol. 2, no. 6, pp. 23–27.

Brodova, I.G., Polents, I.V., Esin, V.O., and Lobov, B.M., Formation regularities of the cast structure of supercooled Al–Ti alloys, Fiz. Met. Metalloved., 1992, no. 1, pp. 84–89.

Norman, A.F. and Tsakiropoulos, P., Rapid solidification of Al–Hf alloys–solidification, microstructures and decomposition of solid-solutions, Int. J. Rapid Solid., 1991, vol. 6, no. 3.

Malek, P., Janecek, M., Smola, B., Bartuska, P., and Plestil, J., Structure and properties of rapidly solidified Al–Zr–Ti alloys, J. Mater. Sci., 2000, vol. 35, pp. 2625–2633.

Popova, E.A., Shubin, A.B., Kotenkov, P.V., Pastukhov, E.A., Bodrova, L.E., and Fedorova, O.M., Al–Ti–Zr master alloys: structure formation, Rus. Metall. (Metally), vol. 2012, no. 5, pp. 357–361.

Popova, E.A., Kotenkov, P.V., Pastukhov, E.A., and Shubin, A.B., Master alloys Al–Sc–Zr, Al–Sc–Ti, and Al–Ti–Zr: their manufacture, composition, and structure, Rus. Metall. (Metally), vol. 2013, no. 8, pp. 590–594.

Popova, E.A., Kotenkov, P.V., and Pastukhov, E.A., Synergetic effect in modifying with master alloys having an aluminide cubic structure, Rus. Metall. (Metally), vol. 2016, no. 2, pp. 189–193.

Kotenkov, P.V., Popova, E.A., and Pastukhov, E.A., Evaluation of modifying ability of Al–Sc–Zr, Al–Sc–Ti, Al–Ti–Zr master alloys, Rasplavy, 2014, no. 4, pp. 21–27.

Murray, J.L., McAlister, A.J., and Kahan, D.J., The Al–Hf (aluminum–hafnium) system, J. Phase Equil., 1998, vol. 19, no. 4, pp. 376–379.

Murray, J.L., The Al–Sc (aluminum–scandium) system, J. Phase Equil., 1998, vol. 19, no. 4, pp. 380–384.

Kerr, H.W., Cisse, J., and Boiling, G.F., On equilibrium and nonequilibrium peritectic transformation, Acta Metall., 1974, vol. 22, pp. 77–686.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.A. Popova, P.V. Kotenkov, A.B. Shubin, E.A. Pastukhov, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Tsvetnaya Metallurgiya, 2017, No. 5, pp. 69–74.

About this article

Cite this article

Popova, E.A., Kotenkov, P.V., Shubin, A.B. et al. Structural Features of Al–Hf–Sc Master Alloys. Russ. J. Non-ferrous Metals 58, 639–643 (2017). https://doi.org/10.3103/S1067821217060086

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821217060086