Abstract

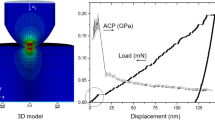

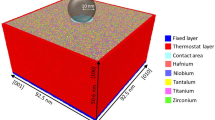

The nanoindentation in the continuous stiffness measurement mode was used to investigate the onset of plasticity at the nanodeformation of cubic boron nitride (cBN). This technique allows us to reveal an elastic-plastic transition in the contact and to measure the yield strength of cBN at the nanoscale. An abrupt elastoplastic transition (a pop-in) was observed in the (111) cBN single crystal as a result of a homogeneous or heterogeneous nucleation of dislocations in the previously dislocations-free region under the contact. The analysis of the data obtained at the homogeneous nucleation of dislocations in the contact region made it possible to experimentally estimate the theoretical shear strength of cBN and its ideal (elastic) hardness. In a sample of the fine-grained cBN with a nanotwinned substructure a smooth elastoplastic transition was observed in consequence of the propagation and multiplication of already existing dislocations in the contact region.

Similar content being viewed by others

References

Kelly, A., Strong solids, Oxford: Clarendon Press, 1973.

Berezhkova, G.V., Nitevidnye cristally (Wiskers), Moscow, Nauka, 1969.

Bei, H., Shim, S., George, E.P., et al., Compressive strengths of molybdenum alloy micropillars prepared using a new technique, Scripta Mater., 2007, vol. 57, pp. 397–400.

Nadgorny, E.M., Dimiduk, D.M., and Uchic, M.D., Size effects in LiF micron-scale single crystals of low dislocation density, J. Mater. Res., 2008, vol. 23, pp. 2829–2835.

Dehm, G., Miniaturized single-crystalline fcc metals deformed in tension: new insights in size dependent plasticity, Progress Mater. Sci., 2009, vol. 54, pp. 664–688.

Michalske, T.A. and Houston, J.E., Dislocation nucleation at nano-scale mechanical contacts, Acta Mater., 1998, vol. 46, pp. 391–396.

Zbib, A.A. and Bahr, D.F., Dislocation nucleation and source activation during nanoindentation yield points, Metal. Mater. Trans., 2007, vol. 38A, pp. 2249–2255.

Zhao, X.F., Langford, R.M., Shapiro, I.P., and Xiao, P., Onset plastic deformation and cracking behavior of silicon carbide under contact load at room temperature, J. Am. Ceram. Soc., 2011, vol. 94, pp. 3509–3514.

Wasmer, K., Gassilloud, R., and Michler, J., Analysis of onset of dislocation nucleation during nanoindentation and nanoscratching of InP, J. Mater. Res., 2012, vol. 27, pp. 320–329.

Dub, S.N., Loboda, P.I., Bogomol, Yu.I., et al., Mechanical properties of HfB2 wiskers, J. Superhard Mater., 2013, vol. 35, no. 4, pp. 234–241.

Zhang, Z.Y., Yang, S., Xu, C.G., Wang, B., and Duan, N.D., Deformation and stress at pop-in of lithium niobate induced by nanoindentation, Scr. Mater., 2014, vol. 77, pp. 56–59.

Chen, J., Wang, W., Qian, L.H., and Lu, K., Critical shear stress for onset of plasticity in a nanocrystalline Cu determined by using nanoindentation, Ibid., 2003, vol. 49, pp. 645–650.

Lilleoden, E.T. and Nix, W.D., Microstructural length-scale effects in the nanoindentation behavior of thin gold films, Acta Mater., 2006, vol. 54, pp. 1583–1593.

Wang, Y., Tam, Eric, and Shen, Y.G., An investigation on the onset of plastic deformation of nanocrystalline solid solution Ti–Al–N films, Eng. Fract. Mech., 2008, vol. 75, pp. 4978–4984.

Wang, Y., Tam, P.L., and Shen, Y.G., Behavior of Ti0.5Al0.5N thin film in nanoscale deformation with different loading rates, Thin Solid Films, 2008, vol. 516, pp. 7641–7647.

Lozano-Mandujano, D., Zarate–Medina, J., Morales-Estrella, R., and Munoz-Saldan, J., Synthesis and mechanical characterization by nanoindentation of polycrystalline YAG with Eu and Nd additions, Ceram. Int. 2013, vol. 39, pp. 3141–3149.

Hay, J., Agee, P., and Herbert, E., Continuous stiffness measurement during instrumented indentation testing, Exp. Tech., 2010, no. 3, pp. 86–94.

Ivashchenko, V. I., Dub, S. N., Scrynskii, P. L., Pogrebnjak, A. D., Sobol’, O. V., Tolmacheva, G. N., Rogoz, V. M., and Sinel’chenko, A. K., Nb–Al–N thin films: structural transition from nanocrystalline solid solution nc-(Nb,Al)N into nanocomposite nc-(Nb,Al)N/a–AlN, J. Superhard Mater., 2016, vol. 38, no. 2, pp. 103–113.

Dub, S.N., Brazhkin, V.V., Belous, V. A., et al., Comparative nanoindentation of single crystals of hard and superhard oxides, Ibid., 2014, vol. 36, no. 4, pp. 217–230.

Tian, Y., Xu, B., Yu, D., Ma, Y., Wang, Y., Jiang, Y., Hu, W., Tang, C., Gao, Y., Luo, K., Zhao, Z., Wang, L., Wen, B., He, J., and Liu, Z., Ultrahard nanotwinned cubic boron nitride, Nature, 2013, vol. 493, pp. 385–388.

Dubrovinskaia, N. and Dubrovinsky, L. Controversy about ultrahard nanotwined cBN; Tian et al. reply, Brief Communications Arising, Ibid., 2013, vol. 502, pp. E1–E3.

Goken, M. and Kempf, M., Pop-ins in nanoindentations—the initial yield point, Z. Metallkd., 2001, vol. 92, pp. 1061–1067.

Zerr, A., Kempf, M., Schwarz, M., Kroke, E., Göken, M., and Riedel, R., Elastic moduli and hardness of cubic silicon nitride, J. Am. Ceram. Soc., 2002, vol. 85, pp. 86–90.

Dedkov, V.S., Ivanov, Yu.F., Lopatin, V.V., and Sharupin, B.N., Special features of the pyrolytic boron nitride structure, Crystallography, 1993, vol. 38, issue 2, pp. 217–222.

Lopatin, V.V., Ivanov, Yu.F., and Dedkov, V.S., Structure-diffraction analysis of nanometer-sized polycrystals, J. Nanostructured Mater., 1994, vol. 4, pp. 669–676.

Khvostantsev, L.G. and Slesarev, V.N., Large-volume high-pressure devices for physical investigations, UFN, 2008, vol. 51, pp. 1059–1063.

Siu, K.W. and Ngan, A.H.W., The continuous stiffness measurement technique in nanoindentation intrinsically modifies the strength of the sample, Phil. Mag., 2013, vol. 93, pp. 449–467.

Cordill, M.J., Moody, N.R., and Gerberich, W.W., Effects of dynamic indentation on the mechanical response of materials, J. Mater. Res., 2008, vol. 23, pp. 1604–1613.

Belyankina, A.V., Sozin, Yu.I., and Petrusha, I.A., Study of single-crystals of sphalerite boron nitride, Synthetic Diamonds, 1978, issue 4, pp. 13–17.

Solozhenko, V.L., Chernyshev, V.V., Fetisov, G.V., Rybakov, V.B., and Petrusha, I.A., Structure analysis of the cubic boron nitride crystals, J. Phys. Chem. Solids, 1990, vol. 51, pp. 1011–1012.

Nikishina, M.V. and Itsenko, P.P., Stability of the nanostructure of pyrolytic boron nitride under a thermobaric influence, Nanosystems, Nanomaterials, Nanotechnologies, 2009, vol. 7, no. 2, pp. 505–516.

Britun, V.F., Kurdyumov, A.V., and Petrusha, I.A., The rBN–hBN–wBN–cBN crystal-oriented transformations in pyrolytic BN, J. Superhard Mater., 2000, vol. 22, no. 2, pp. 1–5.

Dub, S.N. and Petrusha, I.A., Mechanical properties of polycrystalline cBN obtained from pyrolytic gBN by direct transformation technique, High Press. Res., 2006, vol. 26, pp. 71–77.

Solozhenko, V.L., Dub, S.N., and Novikov, N.V., Mechanical properties of cubic BC2N, a new superhard phase, Diamond Relat. Mater., 2001, vol. 10, pp. 2228–2231.

Johnson, K.L., Contact mechanics, Cambridge: Cambridge University Press, 1985.

Brazhkin, V.V., Alexander, G.L., and Hemley, R.J., Harder than diamond: Dreams and reality, Phil. Mag. A, 2002, vol. 82, pp. 231–253.

Davies, R.M., The determination of static and dynamic yield stresses using a steel ball, Proc. R. Soc. London, Ser. A, 1949, vol. 197, pp. 416–432.

Dub, S.N., Lim, Y.Y., and Chaudhri, M.M., Nanohardness of high purity Cu (111) single crystals: The effect of indenter load and prior plastic sample strain, J. Appl. Phys., 2010, vol. 107, art. 043510.

Nikishina, M.V., Bilyavina, N.M., Barsukova, T.P., Britun, B.F., and Petrusha, I.A., Dependence of the hardness of pure polycrystalline materials of cubic boron nitride on structure parameters, Porodorazrushayushchii i metalloobrabatyvayushchii instrument—tekhnika i technologiya ego izgotovleniya i primeneniya (Rock destruction and metal-working tools—techniques and technology of the tool production and applications), Collect. Papers, Kiev: Bakul’ ISM, Nat. Ac. Sci. Ukraine, 2011, issue 14, pp. 299–304.

Tabor, D., Hardness of metals, Oxford: Clarendon Press, 1951.

Song, Z. and Komvopoulos, K., Elastic–plastic spherical indentation: Deformation regimes, evolution of plasticity, and hardening effect, Mech. Mater., 2013, vol. 61, pp. 91–100.

Dubrovinskaia, N., Solozhenko, V.L., Dmitriev, V., Kurakevych, O.O., and Dubrovinsky, L., Superhard nanocomposite of dense polymorphs of boron nitride: Noncarbon material has reached diamond hardness, Appl. Phys. Lett., 2007, vol. 90, art. 101912.

Solozhenko, V.L., Kurakevych, O.O., and Le Godec Y., Creation of nanostuctures by extreme conditions: high-pressure synthesis of ultrahard nanocrystalline cubic boron nitride, Adv. Mater., 2012, vol. 24, pp. 1540–1544.

Sumiya, H., Ishida, Y., Arimoto, K., and Harano, K., Real indentation hardness of nano-polycrystalline cBN synthesized by direct conversion sintering under HPHT, Diamond Relat. Mater., 2014, vol. 48, pp. 47–51.

Novikov, N.V., Dub, S.N., and Malnev, V.I., Microhardness and fracture toughness of cubic boron nitride single crystals, Soviet J. Superhard Mater., 1983, vol. 5, pp. 16–20.

Brookes, C.A., Hooper, R.M., and Lambert, W.A., Identification of slip systems in cubic boron nitride, Phil. Mag., A, 1983, vol. 47, L.9–L.12.

Fujisaki, K., Yokota, H., Furushirod, N., Yamagata, Y., Taniguchi, T., Himeno, R., Makinouchi, A., and Higuchi, T., Development of ultra-fine-grain binderless cBN tool for precision cutting of ferrous materials, J. Mater. Proc. Technol., 2009, vol. 209, pp. 5646–5652.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.N. Dub, I.A. Petrusha, V.N. Bushlya, T. Taniguchi, V.A. Belous, G.N. Tolmachova, A.V. Andreev, 2017, published in Sverkhtverdye Materialy, 2017, Vol. 39, No. 2, pp. 20–34.

About this article

Cite this article

Dub, S.N., Petrusha, I.A., Bushlya, V.M. et al. Theoretical shear strength and the onset of plasticity in nanodeformation of cubic boron nitride. J. Superhard Mater. 39, 88–98 (2017). https://doi.org/10.3103/S1063457617020034

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457617020034