Abstract

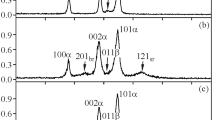

This paper presents research results concerning the influence of ultrasonic burnishing on the structure and mechanical properties of ultra-fine grain titanium alloys: commercial pure titanium BT1-0 and an over stoichiometric alloy with the shape memory Ti49.3Ni50.7. It was shown by the methods of optical microscopy and transmission electronic microscopy that in the surface layer of 20 μm thickness, the ultrasonic burnishing in coarse-grained titanium forms a nanostructure with a grain size of 100 nm, and it additionally decreases the size of crystals from 100 to 30 nm in the nanostructural titanium nickelide. The ultrasonic treatment of alloys greatly increases the strength and micro- and nanohardness of the surface layer, decreases the roughness, forms the gradient nanostructure, improves the lifetime, and expands the functionalities of the items.

Similar content being viewed by others

References

Valiev, R.Z. and Aleksandrov, I.V., Ob’emnye nanostrukturnye metallicheskie materialy: poluchenie, struktura i svoistva (Bulk Nanostructured Metallic Materials: Production, Structure and Properties), Moscow: Akademkniga, 2007.

Edalati, K. and Horita, Z., A review on high-pressure torsion (HPT) from 1935 to 1988, Mater. Sci. Eng. A, 2016, vol. 652, pp. 325–352.

Golovin, Yu.I., Vvedenie v nanotekhniku (Introduction to Nanoengineering), Moscow: Mashinostroenie, 2007.

Wua, X., Jiang, P., Chena, L., Yuan, F., and Zhu, Y.T., Extraordinary strain hardening by gradient structure, Proc. Natl. Acad. Sci. U.S.A., 2014, vol. 111, no. 20, pp. 7197–7201.

Beygelzimer, Y., Estrin, Y., and Kulagin, R., Synthesis of hybrid materials by severe plastic deformation: a new paradigm of SPD processing, Adv. Eng. Mater., 2015, vol. 17. doi doi 10.1002/adem.201500083

Wang, Y., Molotnikov, A., Diez, M., Lapovok, R., Kim, H., Wang, J., and Estrin, Y., Gradient structure produced by three roll planetary milling: numerical simulation and microstructural observations, Mater. Sci. Eng. A, 2015, vol. 639, pp. 165–172.

Yurchenko, L.I., Dyupin, A.P., Gunderov, D.V., Valiev, R.Z., et al., Mechanical properties and structure of high-strength nanostructured nickel-titanium alloys subjected to ECAP and rolling, Faz. Perekh., Uporyad. Sost. Novye Mater., El. Zh., 2006, no. 10.

Kolobov, Y.R., Manokhina, S.S., Kolobova, A.Yu., et al., Shock-wave-induced grain refinement and phase state modification in coarse-grained and nanocrystalline titanium, Tech. Phys. Lett., 2016, vol. 42, no. 9, pp. 959–962.

Stolyarov, V.V., Ugurchiev, U.Kh., Trubitsyna, I.B., et al., Intensive electroplastic deformation of TiNi alloy, Fiz. Tekh. Vys. Davl., 2006, no. 4, pp. 48–51.

Stolyarov, V.V., Deformability and nanostructuring of shape memory TiNi alloys during the electroplastic rolling, Mater. Sci. Eng. A, 2009, vol. 503, pp. 18–20.

Lesyuk, E.A. and Alekhin, V.P., Formirovanie nano- i submikrokristallicheskikh struktur v instrumental’nykh i konstruktsionnykh materialakh i obespechenie ikh termicheskoi stabil’nosti: monografiya (Formation of Nano- and Submicrocrystalline Structures in Instrumental and Structural Materials and Ensuring their Thermal Stability), Moscow: MGIU, 2009.

Mordyuk, B. and Prokopenko, G., Ultrasonic impact peening for the surface properties’ management, J. Sound Vib., 2007, vol. 308, pp. 855–866.

Astashev, V.K. and Krupenin, V.L., Nelineinaya dinamika ul’trazvukovykh tekhnologicheskikh protsessov (Nonlinear Dynamics of Ultrasonic Technological Processes), Moscow: MGUP im. Iv. Fedorova, 2016.

Klimenov, V.A., Kovalevska, Zh.G., Uvarkin, P.V., et al., Ultrasonic finishing treatment and its influence on coating properties, Fiz. Mezomekh., 2004, vol. 7, spec. iss., pp. 157–160.

Lotkov, A.I., Baturin, A.A., Grishkov, V.N., et al., Structural defects and mesorelief of the titanium nichelide surface after severe plastic deformation by an ultrasonic method, Fiz. Mezomekh., 2005, vol. 109, no. 8, pp. 109–112.

Shape Memory Alloys: Fundamentals, Modeling and Applications, Brailovski, V., Prokoshkin, S., Terriault, P., and Trochu, F., Eds., Montreal: ETS, Univ. Québec, 2003.

Cismasiu, C., Shape Memory Alloys, Croatia: SCIYO, 2010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Stolyarov, 2018, published in Problemy Mashinostroeniya i Nadezhnosti Mashin, 2018, No. 6.

About this article

Cite this article

Stolyarov, V.V. Ultrasonic Burnishing of Titanium Alloys. J. Mach. Manuf. Reliab. 47, 537–542 (2018). https://doi.org/10.3103/S1052618818060110

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1052618818060110