Abstract

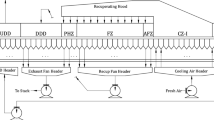

The paper article describes the operating experience of a plant employing state-of-the-art production technology with an MOK-1-592 (TKOM no. 3) indurating machine started up in 2015 at PAO Mikhailovsky GOK. The technical and process solutions implemented in the design of a greenfield production complex is discussed, including a state-of-the-art automated process control system ensuring seamless operation of the equipment in the automated mode and improvement of the product quality. The innovative approach to the performance of the traveling-grate indurating machine and the equipment, which is a part of the heatflow diagram (thermal circuit) of the machine, is based on numerical simulation research of heat and weight transfer in an iron-ore pellet bed. Successful execution of the TKOM no. 3 project is a result of the researchbased and scientifically proven selection of control methods for the pellet production process, the use the state-of-the-industry algorithms for control over the operation modes of the entire production line.

Similar content being viewed by others

References

Evstyugin, S.N., Solodukhin, A.A., Parfenov, A.K., and Tomilin, A.A., Technology for new pelletization plant at OAO Mikhailovskii GOK, Steel Transl., 2010, vol. 40, no. 9, pp. 816–819.

Evstyugin, S.N., Starodumov, A.V., Kruglov, V.N., and Doshchitsyn, N.F., Use of the Granulometer system for continuous non-contact grain-size determination of lumpy materials, Stal’, 2003, no. 1, pp. 36–38.

Starodumov, A.V., Evstyugin, S.N., Kruglov, V.M., and Lisienko, V.G., Automated green pelletizing process control system Grain size indicator, Stal’, 2008, no. 12, pp. 37–39.

Bokovikov, B.A., Bragin, V.V., Evstyugin, S.N., et al., Teplofizicheskie zakonomernosti termoobrabotki zhelezorudnykh okatyshei na konveiernoi mashine (matematicheskoe modelirovanie) (Thermal and Physical Regularities of the Iron Ore Pellet Thermal Treatment on Conveyor: Mathematical Modeling), Yekaterinburg: Ural. Izd. Poligr. Tsentr, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Bragin, A.V. Starodumov, A.V. Varichev, A.A. Ugarov, S.I. Kretov, A.V. Kozub, A.L. Kuznetsov, A.A. Lavrinenko, 2017, published in Stal’, 2017, No. 12, pp. 2–5.

The article was translated by the authors.

About this article

Cite this article

Bragin, V.V., Starodumov, A.V., Varichev, A.V. et al. Control Over the Innovative Pellet Production Process at TKOM No. 3 at PAO ‘Mikhailovskiy GOK’ Employing the State-of-the-Art Automated Process Control System. Steel Transl. 47, 802–805 (2017). https://doi.org/10.3103/S096709121712004X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S096709121712004X