Abstract

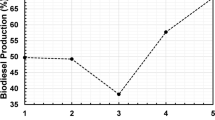

Acidic crude palm oil (ACPO) produced from palm oil mills with an acid value of 18 mg g−1 was considered to be a possible feedstock for biodiesel production. Due to its high acidity, conventional transesterification cannot be applied directly for biodiesel production. Methane sulphonic acid (MSA, CH3SO3H) is used to reduce the acidity prior to the alkaline transesterification reaction. The laboratory-scale experiments involved an MSA to ACPO dosage of 0.25–3.5 %, a molar ratio (methanol to ACPO) from 4: 1 to 20: 1, reaction temperature of 40–80°C, reaction time of 3–150 min, and stirrer speed of 100–500 min−1. The optimum esterification reaction conditions were 1 % of catalyst to ACPO, with a molar ratio of methanol to ACPO of 8: 1, a stirring speed of 300 min−1, for 30 min and at 60°C. Under these conditions, the FFA content was reduced from 18 mg g−1 to less than 1 mg g−1 and with a yield of 96 %. The biodiesel produced met the EN14214 standard specifications. MSA was recycled for three times without losing its activity. The biodiesel produced in a two-stage process has a low acid value (0.14 mg g−1).

Similar content being viewed by others

References

Canakci, M. (2007). The potential of restaurant waste lipids as biodiesel feedstocks. Bioresource Technology, 98, 183–190. DOI: 10.1016/j.biortech.2005.11.022.

Chew, T. L., & Bhatia, S. (2008). Catalytic processes towards the production of biofuels in a palm oil and oil palm biomassbased biorefinery. Bioresource Technology, 99, 7911–7922. DOI: 10.1016/j.biortech.2008.03.009.

Chongkhong, S., Tongurai, C., Chetpattananondh, P., & Bunyakan, C. (2007). Biodiesel production by esterification of palm oil fatty acid distillate. Biomass and Bioenergy, 31, 563–568. DOI: 10.1016/j.biombioe.2007.03.001.

Di Serio, M., Tesser, R., Pengmei, L., & Santacesaria, E. (2008) Heterogeneous catalyst for biodiesel production. Energy & Fuels, 22, 207–217. DOI: 10.1021/ef700250g.

Demirbas, A. (2009). Biohydrogen for future engine fuel demands. London, UK: Springer. DOI: 10.1007/978-1-84882-511-6.

Elsheikh, Y. A., Man, Z., Bustam, M. A., Yusup, S., & Wilfred, C. D. (2011). Brønsted imidazolium ionic liquids: Synthesis and comparison of their catalytic activities as precatalyst for biodiesel production through two stage process. Energy Conversion and Management, 52, 804–809. DOI: 10.1016/j.enconman.2010.08.005.

European Committee for Standardization (2008). European standard: Automotive fuels — Fatty acid methyl esters (FAME) for diesel engines — Requirements and test methods EN 14214:2008+A1:2009. Brussels, Belgium.

European Committee for Standardization (2009). European standards. Retrieved October, 2011, from http://www.cen.eu/cen/Products/Search/Pages/default.aspx

Guan, G., Kusakabe, K., Sakurai, N., & Moriyama, K. (2009) Transesterification of vegetable oil to biodiesel fuel using acid catalysts in presence of dimethyl ether. Fuel, 88, 81–86. DOI: 10.1016/j.fuel.2008.07.021.

Han, M., Yi, W., Wu, Q., Liu, Y., Hong, Y., & Wang, D (2009). Preparation of biodiesel from waste oils catalyzed by a Brønsted acidic ionic liquid. Bioresource Technology, 100, 2308–2310. DOI: 10.1016/j.biortech.2008.10.046.

Hayyan, A., Alam, Md. Z., Mirghani, M. E. S., Kabbashi, N. A., Hakimi, N. I. N. M., Siran, Y. M., & Tahiruddin, S. (2010a) Sludge palm oil as a renewable raw material for biodiesel production by two-step processes. Bioresource Technology, 101, 7804–7811. DOI: 10.1016/j.biortech.2010.05.045.

Hayyan, A., Alam, Md. Z., Mirghani, M. E. S., Kabbashi, N. A., Hakimi, N. I. N. M., Siran, Y. M., & Tahiruddin, S. (2011a) Reduction of high content of free fatty acid in sludge palm oil via acid catalyst for biodiesel production. Fuel Processing Technology, 92, 920–924. DOI: 10.1016/j.fuproc.2010.12.011.

Hayyan, M., Mjalli, F. S., Hashim, M. A., & AlNashef, I. M (2010b). A novel technique for separating glycerine from palm oil-based biodiesel using ionic liquids. Fuel Processing Technology, 91, 116–120. DOI: 10.1016/j.fuproc.2009.09.002.

Hayyan, A., Mjalli, F. S., Hashim, M. A., Hayyan, M., AlNashef, I. M., Al-Zahrani, S. M., & Al-Saadi, M. A. (2011b). Ethanesulfonic acid-based esterification of industrial acidic crude palm oil for biodiesel production. Bioresource Technology, 102, 9564–9570. DOI: 10.1016/j.biortech.2011.07.074.

Kuntom, A., Lin, S. W., Ai, T. Y., Idris, N. A., Yusof, M., Sue, T. T., & Ibrahim, N. A. (2005). Test methods. Bangi, Malaysia: Malaysian palm oil board (MPOB).

Liu, K. S. (1994). Preparation of fatty acid methyl esters for gas-chromatographic analysis of lipids in biological materials. Journal of the American Oil Chemists’ Society, 71, 1179–1187. DOI: 10.1007/BF02540534.

Ma, F., & Hanna, M. A. (1999). Biodiesel production: a review. Bioresource Technology, 70, 1–15. DOI: 10.1016/S0960-8524(99)00025-5.

Mjalli, F. S., & Hussain, M. A. (2009). Approximate predictive versus self-tuning adaptive control strategies of biodiesel reactors. Industrial & Engineering Chemistry Research, 48, 11034–11047. DOI: 10.1021/ie900930k.

Mjalli, F. S., San, L. K., Yin, K. C., & Hussain, M. A. (2009) Dynamics and control of a biodiesel transesterification reactor. Chemical Engineering & Technology, 32, 13–26. DOI: 10.1002/ceat.200800243.

Naik, M., Meher, L. C., Naik, S. N., & Das, L. M. (2008) Production of biodiesel from high free fatty acid Karanja (Pongamia pinnata) oil. Biomass and Bioenergy, 32, 354–357. DOI: 10.1016/j.biombioe.2007.10.006.

Srivastava, A., & Prasad, R. (2000). Triglycerides-based diesel fuels. Renewable and Sustainable Energy Reviews, 4, 111–133. DOI: 10.1016/S1364-0321(99)00013-1.

Sharma, Y. C., Singh, B., & Upadhyay, S. N. (2008). Advancements in development and characterization of biodiesel: A review. Fuel, 87, 2355–2373. DOI: 10.1016/j.fuel.2008.01.014.

Wang, Y., Ou, S., Liu, P., Xue, F., & Tang, S. (2006). Comparison of two different processes to synthesize biodiesel by waste cooking oil. Journal of Molecular Catalysis A: Chemical, 252, 107–112. DOI: 10.1016/j.molcata.2006.02.047.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hayyan, A., Mjalli, F.S., Mirghani, M.E.S. et al. Treatment of acidic palm oil for fatty acid methyl esters production. Chem. Pap. 66, 39–46 (2012). https://doi.org/10.2478/s11696-011-0102-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11696-011-0102-6