Astract

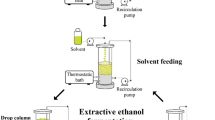

Ethanol production in a bioreactor with integrated membrane distillation (MD) module has been investigated. A hydrophobic capillary polypropylene membrane (Accurel PP V8/2 HF), with an external/internal diameter ratio, d out/d in = 8.6 mm/5.5 mm and pore size 0.2 μm, was used in these studies. The products (mainly ethanol and acetic acid) formed during the fermentation of sugar with Saccharomyces cerevisiae inhibited the process. These products were selectively removed from the fermentation broth by the MD process, which increased the efficiency of the conversion of sugar to alcohol from 0.45 g to 0.5 g EtOH per g of fermented sucrose. The bioreactor efficiency also increased by almost 30 %. Separation of alcohol by the MD generates a higher yield of ethanol in the permeate than in the broth. The enrichment coefficient amounted to 4-8, and depended on the ethanol concentration in the broth. The separated solutions did not wet the membrane in use for 2500 h of the MD experiments and the retention of inorganic solutes was close to 100 %.

Similar content being viewed by others

References

Bai, F.W., Anderson, W. A., & Moo-Young, M. (2008). Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnology Advances, 26, 89–105. DOI: 10.1016/j.biotech adv.2007.09.002.

Barancewicz, M., Sasim, M., & Gryta, M. (2009). Zastosowanie chromatografii jonowej do badania przebiegu fermentacji. Prace i Studia, 77, 89–101.

Cardona, C. A., & Sanchéz, Ó. J. (2007). Fuel ethanol production: Process design trends and integration opportunities. Bioresource Technology, 98, 2415–2457. DOI: 10.1016/j.bior tech.2007.01.002.

Choi, G.-W., Kang, H.-W., & Moon, S.-K. (2009). Repeatedbatch fermentation using flocculent hybrid, Saccharomyces cerevisiae CHFY0321 for efficient production of bioethanol. Applied Microbiology and Biotechnology, 84, 261–269. DOI: 10.1007/s00253-009-1946-3.

Demirbas, A. (2007). Progress and recent trends in biofuels. Progress in Energy and Combustion Science, 33, 1–18. DOI: 10.1016/j.pecs.2006.06.001.

Escobar, J. M., Rane, K. D., & Cheryan, M. (2001). Ethanol production in a membrane bioreactor. Applied Biochemistry and Biotechnology, 91–93, 283–296. DOI: 10.1385/ABAB:91-93:1-9:283.

Gryta, M. (2007). Effect of iron oxides scaling on the MD process performance. Desalination, 216, 88–102. DOI: 10.1016/j.desal.2007.01.002.

Gryta, M. (2001). The fermentation process integrated with membrane distillation. Separation and Purification Technology, 24, 283–296. DOI: 10.1016/S1383-5866(01)00132-0.

Gryta, M., & Barancewicz, M. (2010). Influence of morphology of PVDF capillary membranes on the performance of direct contact membrane distillation. Journal of Membrane Science, 358, 158–167. DOI: 10.1016/j.memsci.2010.04.044.

Gryta, M., Morawski, A. W., & Tomaszewska, M. (2000). Ethanol production in membrane distillation bioreactor. Catalysis Today, 56, 159–165. DOI: 10.1016/S0920-5861(99)00272-2.

Gyamerah, M., & Glover, J. (1996). Production of ethanol by continuous fermentation and liquid-liquid extraction. Journal of Chemical Technology and Biotechnology, 66, 145–152. DOI: 10.1002/(SICI)1097-4660(199606)66:2<145::AIDJCTB484>3.0.CO;2-2.

Kargupta, K., Datta, S., & Sanyal, S. K. (1998). Analysis of the performance of a continuous membrane bioreactor with cell recycling during ethanol fermentation. Biochemical Engineering Journal, 1, 31–37. DOI: 10.1016/S1369-703X(97)00006-5.

Kaseno, Miyazawa, I., & Kokugan, T. (1998). Effect of product removal by a pervaporation on ethanol fermentation. Journal of Fermentation and Bioengineering, 86, 488–493. DOI: 10.1016/S0922-338X(98)80157-8.

Maiorella, B. L., Blanch, H. W., & Wilke, C. R. (1984). Economic evaluation of alternative ethanol fermentation processes. Biotechnology and Bioengineering, 26, 1003–1025. DOI: 10.1002/bit.260260902.

Park, B. G., Lee, W. G., Chang, Y. K., & Chang, H. N. (1999). Long-term operation of continuous high cell density culture of Saccharomyces cerevisiae with membrane filtration and on-line cell concentration monitoring. Bioprocess Engineering, 21, 97–100. DOI: 10.1007/PL00009070.

Udriot, H., Ampuero, S., Marison, I. W., & von Stockar, U. (1989). Extractive fermentation of ethanol using membrane distillation. Biotechnology Letters, 11, 509–514. DOI: 10.1007/BF01026651.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barancewicz, M., Gryta, M. Ethanol production in a bioreactor with an integrated membrane distillation module. Chem. Pap. 66, 85–91 (2012). https://doi.org/10.2478/s11696-011-0088-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11696-011-0088-0