Abstract

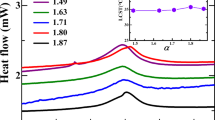

Swelling properties of amphoteric polyacrylamide (AmPAM) dispersions were investigated by measurements of apparent viscosity and particle morphology. AmPAM dispersion was prepared by dispersion polymerization in aqueous solution of ammonium sulphate. Changes of particles during dispersion polymerisation of AmPAM were simulated and compared with anionic and cationic polyacrylamide (APAM and CPAM, respectively). Sample viscosity and particle morphology were obtained using a rotational viscometer and optical microscope. It was found that small molecules or ions enter and swell particles in the AmPAM dispersion when (NH4)2SO4 concentration decreases. Similarly, monomers, including acrylamide, acrylic acid, and methacrylatoethyl trimethyl ammonium chloride, have the same effects on the AmPAM dispersion but the effect degree is different. Swelling properties of the AmPAM dispersion were different from those of the APAM and CPAM dispersions due to their different ionic nature, type of stabiliser, media, etc. Particles in the APAM or CPAM dispersions were swelled less than those in the AmPAM dispersion.

Similar content being viewed by others

References

Abdel-Razik, H. H. (2008). Synthesis and characterization of diaminomaleonitrile-functionalized polystyrene grafts for application in pervaporation separation. Chemical Papers, 62, 404–409. DOI: 10.2478/s11696-008-0037-8.

Bartoň, J., Kawamoto, S., Fujimoto, K., Kawaguchi, H., & Capek, I. (2000). Preparation of partly hydrophobized, crosslinked polyacrylamide particles by terpolymerization of acrylamide/N,N-methylenebisacrylamide/styrene in inverse microemulsion. Polymer International, 49, 358–366. DOI: 10.1002/(SICI)1097-0126(200004)49:4<358::AID-PI376>3.0.CO;2-1.

Bočková, J., Vojtová, L., Přikryl, R., Čechal, J., & Jančář, J. (2008). Collagen-grafted ultra-high molecular weight polyethylene for biomedical applications. Chemical Papers, 62, 580–588. DOI: 10.2478/s11696-008-0076-1.

Bradley, M., Vincent, B., & Burnett, G. (2009). Uptake and release of surfactants from polyampholyte microgel particles. Colloid and Polymer Science, 287, 345–350. DOI: 10.1007/s00396-008-1978-8.

Chen, D., Liu, X., Yue, Y., Zhang, W., & Wang, P. (2006). Dispersion copolymerization of acrylamide with quaternary ammonium cationic monomer in aqueous salts solution. European Polymer Journal, 42, 1284–1297. DOI: 10.1016/j.eurpolymj.2005.12.007.

Chen, Q., Liu, X., Yang, Q., Xu, K., Zhang, W., Song, C., & Wang, P. (2008). Low cationic proportion ampholytic polymer: Synthesis, solution properties and interaction with anionic surfactant. Polymer Bulletin, 60, 545–554. DOI: 10.1007/s00289-007-0885-3.

Cho, M. S., Yoon, K. J., & Song, B. K. (2002). Dispersion polymerization of acrylamide in aqueous solution of ammonium sulfate: Synthesis and characterization. Journal of Applied Polymer Science, 83, 1397–1405. DOI: 10.1002/app.2300.

Ezell, R. G., Gorman, I., Lokitz, B., Treat, N., McConaughy, S. D., & McCormick, C. L. (2006). Polyampholyte terpolymers of amphoteric, amino acid-based monomers with acrylamide and (3-acrylamidopropyl)trimethyl ammonium chloride. Journal of Polymer Science Part A: Polymer Chemistry, 44, 4479–4493. DOI: 10.1002/pola.21543.

Fujioka, M., Kurihara, H., Kawamura, R., Sato, H., Tsuchiya, K., & Ogino, K. (2008). Preparation of poly(4-butyltriphenylamine) particles by chemical oxidative dispersion polymerization. Colloid and Polymer Science, 286, 313–318. DOI: 10.1007/s00396-007-1779-5.

Grahame, D. C. (1947). The electrical double layer and the theory of electrocapillarity. Chemical Reviews, 41, 441–501. DOI: 10.1021/cr60130a002.

Guha, S., & Mandal, B. M. (2004). Dispersion polymerization of acrylamide III. Partial isopropyl ester of poly(vinyl methyl ether-alt-maleic anhydride) as a stabilizer. Journal of Colloid and Interface Science, 271, 55–59. DOI: 10.1016/j.jcis.2003.10.023.

Hao, J. (2001). Microemulsion polymerization of acrylamide and styrene: Effect of the structures of reaction media. Journal of Polymer Science Part A: Polymer Chemistry, 39, 3320–3334. DOI: 10.1002/pola.1315.

Hong, J., Hong, C. K., & Shim, S. E. (2007). Synthesis of polystyrene microspheres by dispersion polymerization using poly(vinyl alcohol) as a steric stabilizer in aqueous alcohol media. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 302, 225–233. DOI: 10.1016/j.colsurfa.2007.02.027.

Ishimatsu, R., Shigematsu, F., Hakuto, T., Nishi, N., & Kakiuchi, T. (2007). Structure of the electrical double layer on the aqueous solution side of the polarized interface between water and a room-temperature ionic liquid, tetrahexylammonium bis(trifluoromethylsulfonyl)imide. Langmuir, 23, 925–929. DOI: 10.1021/la0623073.

Itoh, T., Fukutani, K., Hino, M., Ihara, E., & Inoue, K. (2009). Effects of polystyrene-b-poly(aminomethyl styrene)s as stabilizers on dispersion polymerization of styrene in alcoholic media. Journal of Colloid and Interface Science, 330, 292–297. DOI: 10.1016/j.jcis.2008.10.052.

Kawaguchi, S., & Ito, K. (2005). Dispersion polymerization. Advances in Polymer Science, 175, 299–328. DOI: 10.1007/b100118.

Lee, J. M., Lee, K., Min, K., & Choe, S. (2008). The effect of polystyrene-block-poly(4-vinylpyridine) prepared by a RAFT method in the dispersion polymerization of styrene. Current Applied Physics, 8, 732–735. DOI: 10.1016/j.cap.2007.04.031.

Musial, W., Kokol, V., Fecko, T., & Voncina, B. (2010a). Morphological patterns of poly(N-isopropylacrylamide) derivatives synthesized with EGDMA, DEGDMA, and TEGDMA crosslinkers for application as thermosensitive drug carriers. Chemical Papers, 64, 791–798. DOI: 10.2478/s11696-010-0065-z.

Musial, W., Vincent, B., Szumny, A., & Voncina, B. (2010b). Morphological characteristics of modified freeze-dried poly (N-isopropylacrylamide) microspheres studied by optical microscopy, SEM, and DLS. Chemical Papers, 64, 602–612. DOI: 10.2478/s11696-010-0041-7.

Ray, B., & Mandal, B. M. (1999). Dispersion polymerization of acrylamide: Part II. 2,2′-Azobisisobutyronitrile initiator. Journal of Polymer Science Part A: Polymer Chemistry, 37, 493–499. DOI: 10.1002/(SICI)1099-0518(19990215)37:4<493::AID-POLA13>3.0.CO;2-Y.

Rintoul, I., & Wandrey, C. (2009). Magnetic field effects on the copolymerization of water-soluble and ionic monomers. Journal of Polymer Science Part A: Polymer Chemistry, 47, 373–383. DOI: 10.1002/pola.23152.

Schmid, A., Fujii, S., & Armes, S. P. (2006). Polystyrene-silica nanocomposite particles via alcoholic dispersion polymerization using a cationic azo initiator. Langmuir, 22, 4923–4927. DOI: 10.1021/la060308p.

Shen, S., Sudol, E. D., & El-Aasser, M. S. (1993). Control of particle size in dispersion polymerization of methyl methacrylate. Journal of Polymer Science Part A: Polymer Chemistry, 31, 1393–1402. DOI: 10.1002/pola.1993.080310606.

Song, B. K., Cho, M. S., Yoon, K. J., & Lee, D. C. (2003). Dispersion polymerization of acrylamide with quaternary ammonium cationic comonomer in aqueous solution. Journal of Applied Polymer Science, 87, 1101–1108. DOI: 10.1002/app.11559.

Tao, Z., Yang, W., Zhou, H., Wang, C., & Fu, S. (2000). Morphological investigation of styrene and acrylamide polymer microspheres prepared by dispersion copolymerization. Colloid and Polymer Science, 278, 509–516. DOI: 10.1007/s003960050548.

Wang, L.-J., Wang, J.-P., Yuan, S.-J., Zhang, S.-J., Tang, Y., & Yu, H.-Q. (2009). Gamma radiation-induced dispersion polymerization in aqueous salts solution for manufacturing a cationic flocculant. Chemical Engineering Journal, 149, 118–122. DOI: 10.1016/j.cej.2008.10.010.

Wu, Y., Wang, C., & Xu, J. (2010). Aqueous dispersion polymerization of amphoteric polyacrylamide. Journal of Applied Polymer Science, 115, 1131–1137. DOI: 10.1002/app.31201.

Wu, Y. M., Chen, Q. F., Xu, J., & Bi, J. M. (2008). Aqueous dispersion polymerization of acrylamide with quaternary ammonium cationic comonomer. Journal of Applied Polymer Science, 108, 134–139. DOI: 10.1002/app.27464.

Wu, Y. M., Wang, Y. P., Yu, Y. Q., Xu, J., & Chen, Q. F. (2006). Dispersion polymerization of acrylamide with 2-acrylamido-2-methyl-1-propane sulfonate in aqueous solution. Journal of Applied Polymer Science, 102, 2379–2385. DOI: 10.1002/app.24494.

Yu, H.-Q., & Cong, R. (2010). Preparation and characterization of hydrogels based on acryloyl end-capped four-arm star-shaped poly(ethylene glycol)-branched-oligo(L-lactide) via Michael-type addition reaction. Chemical Papers, 64, 619–624. DOI: 10.2478/s11696-010-0055-1.

Zhang, Y., Lin, H., Li, Z., & Lv, P. (2008). Improvement of shrimp (Penaeus vannamei) allergens purification by ammonium sulfate precipitation. Food and Drug, 10, 50–52. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C., Xu, J., Zhang, J. et al. Swelling properties of particles in amphoteric polyacrylamide dispersion. Chem. Pap. 65, 315–323 (2011). https://doi.org/10.2478/s11696-011-0012-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11696-011-0012-7