Abstract

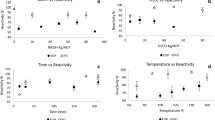

Two basic mechanisms of displacement washing of pulp fibres were investigated. Experiments were carried out in a laboratory washing cell that simulated a single stage of displacement washing. The step-change method has been employed in investigation of alkali lignin profile in outlet stream of washing effluents. The addition of urea to wash water resulted in a decrease of the liquid layer immobilized on the fibre surface. It had a positive effect on the washing efficiency expressed in terms of the void local efficiency.

Similar content being viewed by others

Abbreviations

- A:

-

cross-sectional area of pulp bed m2

- a V :

-

effective specific surface m−1

- B:

-

permeability coefficient m2

- C:

-

consistency of pulp kg m−3

- D:

-

axial dispersion coefficient m2 s−1

- E:

-

local efficiency

- Eɛ :

-

void local efficiency defined by eqn (6)

- h:

-

thickness of bed m

- K:

-

Kozeny constant in eqn (2)

- Lɛ :

-

mass of spent liquor in void volume of bed kg

- L 0 :

-

total mass of spent liquor in bed kg

- n:

-

number of measurements

- ΔP :

-

pressure drop Pa

- Pe:

-

Péclet number (= hu/Dɛ)

- RWɛ :

-

wash liquor ratio defined by eqn (8)

- t:

-

time s

- t m :

-

mean residence time defined by eqn (10) s

- u:

-

superficial wash liquid velocity m s−1

- V:

-

volume of wash liquid m3

- v:

-

effective specific volume of fibres m3 kg−1

- WYɛ :

-

void wash yield defined by eqn (7)

- w:

-

urea mass fraction in the wash liquid mass %

- δ:

-

mean relative quadratic deviation of void local bed efficiency, E ɛ , defined as

$$\delta = \sqrt {\frac{1}{n}\sum\limits_{i = 1}^{i = n} {\left( {\frac{{E_{\varepsilon ,\exp } - E_{\varepsilon ,calc} }}{{E_{\varepsilon ,\exp } }}} \right)_i^2 } } \times 100 \% $$ - ɛ:

-

average effective porosity of bed

- µ:

-

viscosity of wash liquid Pa s

- ρ:

-

solute (alkali lignin) concentration kg m−3

- τ:

-

space-time defined by eqn (9) s

- avg:

-

average concentration in bed

- calc:

-

calculated value

- e:

-

exit stream

- exp:

-

experimental value

- i:

-

inlet stream

- 0:

-

initial concentration in bed at t = 0

References

Laxén, T., J. Pulp Paper Sci. 87, T148 (1986).

Trinh, D. T. and Crotogino, R. H., J. Pulp Paper Sci. 88, J126 (1987).

Favis, B. D. and Goring, D. A. I., J. Pulp Paper Sci. 85, J139 (1984).

Potůček, F. and Pulcer, M., Chem. Pap. 58, 377 (2004).

Milichovský, M., Cellulose Chem. Technol. 26, 607 (1992).

Ingmanson, W. L., Chem. Eng. Prog. 49, 577 (1953).

Kyan, C. P., Wasan, D. T., and Kintner, R. C., Ind. Eng. Chem. Fundam. 9, 596 (1970).

Potůček, F. and Marhanová, M., Sci. Pap. Univ. Pardubice, Ser. A4, 223 (1998).

Cullinan, H. T., Appita J. 44, 91 (1991).

Potůček, F., Collect. Czech. Chem. Commun. 62, 626 (1997).

Potůček, F. and Marhanová, M., Cellulose Chem. Technol. 36, 527 (2002).

Potůček, F., Cellulose Chem. Technol. 37, 141 (2003).