Abstract

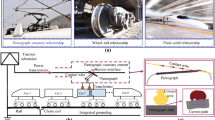

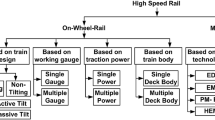

Two types of high power alternating current (AC) locomotive in China are prone to serious high-order polygonal wear, which has significant negative effects on the operation of locomotives. This study investigates factors influencing polygonal wear in locomotive wheels and determines methods of minimizing operation damage. We designed experiments to analyze the process of polygonization formation of wheels to identify the key influencing factors, finding that natural vibration of wheelsets is the central inherent factor of wheel polygonization and that these vibrations can be easily stimulated by wheel or rail irregularities. We found that poor re-profiling quality is the key external factor in these irregularities. The wheelset bending resonance is activated when the remaining wheel polygonal wear has a wavelength of 200 mm in the 1/3 octave band, in turn leading to significant increases of wheel polygonal wear. In this study, we review a new wheelset design that can mitigate and/or eliminate the polygonal wheel wear due to increased stiffness in wheel bending. We evaluate the potential capacity of the newly designed wheelset and propose two proven effective measures to further improve the wheel re-profiling quality for polygonal wear.

抽象

目的

某型大功率交流传动机车容易出现严重的车轮多边形磨耗。本文旨在通过总结试验研究结果, 归纳车轮多边形磨耗的形成过程和关键影响因素, 提出相应的解决措施, 并对解决措施进行数值验证。

创新点

1. 揭示了机车车轮多边形磨耗的形成过程, 并明确了其关键影响因素;2. 对轮对结构进行改进设计来抑制车轮多边形磨耗, 并从数值仿真的角度对其效果进行了验证。

方法

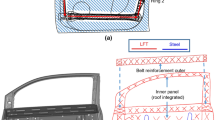

1. 通过总结试验测试结果, 明确车轮多边形磨耗的形成过程和关键影响因素(图2);2. 通过轮对试验模态和数值模态分析, 掌握轮对的模态特性(图4和6);3. 通过轮对动力响应分析, 验证轮对结构改进设计对抑制车轮多边形磨耗的效果(图8和12);4. 通过理论推导, 分析不落轮镟修不能有效消除车轮多边形磨耗的原因(公式(1)~(6))。

结论

1. 轮对弯曲振动是导致车轮形成高阶多边形磨耗的内在因素, 而较差的车轮镟修效果是车轮多边形磨耗发展较快的外在因素;2. 车轮横向刚度较低, 容易导致轮对固有振动被轮轨不平顺激发, 从而对车轮多边形磨耗的形成产生重要影响;3. 改变轮对镟修时的固定方式, 或者改变镟床驱动轮间距可以有效提升车轮镟修质量;4. 通过提高车轮横向刚度, 改变轮对固有振动特性, 理论上能有效缓解车轮多边形磨耗的形成。

Similar content being viewed by others

References

Barke DW, Chiu WK, 2005. A review of the effects of out-of-round wheels on track and vehicle components. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 219(3):151–175. https://doi.org/10.1243/095440905X8853

Cai WB, Chi MR, Wu XW, et al., 2019a. Experimental and numerical analysis of the polygonal wear of high-speed trains. Wear, 440–441:203079. https://doi.org/10.1016/j.wear.2019.203079

Cai WB, Chi MR, Tao GQ, et al., 2019b. Experimental and numerical investigation into formation of metro wheel polygonalization. Shock and Vibration, 2019:1538273. https://doi.org/10.1155/2019/1538273

Chen GX, Jin XS, Wu PB, et al., 2011. Finite element study on the generation mechanism of polygonal wear of railway wheels. Journal of the China Railway Society, 33(1):14–18 (in Chinese). https://doi.org/10.3969/j.issn.1001-8360.2011.01.003

Dai H, Li D, Wang J, et al., 2018. Study on the mechanism of high order out of round roughness of high speed railway train’s wheel. Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/wheel System, p.189–195.

Fröhling R, Spangenberg U, Reitmann E, 2019. Root cause analysis of locomotive wheel tread polygonisation. Wear, 432–433:102911. https://doi.org/10.1016/j.wear.2019.05.026

Fu B, Bruni S, Luo SH, 2019. Study on wheel polygonization of a metro vehicle based on polygonal wear simulation. Wear, 438–439:203071. https://doi.org/10.1016/j.wear.2019.203071

ISO (International Organization for Standardization), 2013. Acoustics—Railway Applications—Measurement of Noise Emitted by Railbound Vehicles, ISO 3095:2013. ISO, Geneva, Switzerland.

Jin XS, Wu L, Fang JY, et al., 2012. An investigation into the mechanism of the polygonal wear of metro train wheels and its effect on the dynamic behaviour of a wheel/rail system. Vehicle System Dynamics, 50(12):1817–1834. https://doi.org/10.1080/00423114.2012.695022

Johansson A, Andersson C, 2005. Out-of-round railway wheels—a study of wheel polygonalization through simulation of three-dimensional wheel-rail interaction and wear. Vehicle System Dynamics, 43(8):539–559. https://doi.org/10.1080/00423110500184649

Kalousek J, Johnson KL, 1992. An investigation of short pitch wheel and rail corrugations on the Vancouver mass transit system. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 206(2):127–135. https://doi.org/10.1243/PIME_PROC_1992_206_226_02

Li D, Dai H, Jia X, et al., 2018. Out-of-round of subway wheel caused by rail flexibility. Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/wheel System, p.529–535.

Ma WH, Song RR, Luo SH, 2016. Study on the mechanism of the formation of polygon-shaped wheels on subway vehicles. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230(1): 129–137. https://doi.org/10.1177/0954409714529269

Peng B, Iwnicki S, Shackleton P, et al., 2019. The influence of wheelset flexibility on polygonal wear of locomotive wheels. Wear, 432–433:102917. https://doi.org/10.1016/j.wear.2019.05.032

Ren DX, Tao GQ, Liu H, et al., 2019. Analysis of abnormal turning repair for locomotive wheels with polygonal wear and improvement measures. Journal of Central South University (Science and Technology), 50(9):2317–2326 (in Chinese). https://doi.org/10.11817/j.issn.1672-7207.2019.09.029

Spangenberg U, 2020. Variable frequency drive harmonics and interharmonics exciting axle torsional vibration resulting in railway wheel polygonization. Vehicle System Dynamics, 58(3):404–424. https://doi.org/10.1080/00423114.2019.1581235

Spangenberg U, Fröhling RD, 2020. Solving locomotive wheel polygonisation by reducing variable frequency drive interharmonics. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, in press. https://doi.org/10.1177/0954409720904279

Tao GQ, Wang LF, Wen ZF, et al., 2018a. Experimental investigation into the mechanism of the polygonal wear of electric locomotive wheels. Vehicle System Dynamics, 56(6):883–899. https://doi.org/10.1080/00423114.2017.1399210

Tao GQ, Wang LF, Wen ZF, et al., 2018b. Measurement and assessment of out-of-round electric locomotive wheels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 232(1):275–287. https://doi.org/10.1177/0954409716668210

Tao GQ, Wen ZF, Liang XR, et al., 2019. An investigation into the mechanism of the out-of-round wheels of metro train and its mitigation measures. Vehicle System Dynamics, 57(1):1–16. https://doi.org/10.1080/00423114.2018.1445269

Tao GQ, Wen ZF, Chen GS, et al., 2020a. Locomotive wheel polygonisation due to discrete irregularities: simulation and mechanism. Vehicle System Dynamics, in press. https://doi.org/10.1080/00423114.2020.1737148

Tao GQ, Xie CX, Wang HY, et al., 2020b. An investigation into the mechanism of high-order polygonal wear of metro train wheels and its mitigation measures. Vehicle System Dynamics, in press. https://doi.org/10.1080/00423114.2020.1770810

Tao GQ, Wen ZF, Jin XS, et al., 2020c. Polygonisation of railway wheels: a critical review. Railway Engineering Science, 28:317–345. https://doi.org/10.1007/s40534-020-00222-x

Wei L, Zong LX, Luo SH, et al., 2016. Research into the problem of wear creating a polygon-shaped wheel on metro trains. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230(1):43–55. https://doi.org/10.1177/0954409714523584

Wu BW, Qiao QF, Chen GX, et al., 2020. Effect of the unstable vibration of the disc brake system of high-speed trains on wheel polygonalization. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 234(1):80–95. https://doi.org/10.1177/0954409719833787

Wu XW, Chi MR, Wu PB, 2015. Influence of polygonal wear of railway wheels on the wheel set axle stress. Vehicle System Dynamics, 53(11):1535–1554. https://doi.org/10.1080/00423114.2015.1063674

Wu XW, Rakheja S, Qu S, et al., 2018. Dynamic responses of a high-speed railway car due to wheel polygonalisation. Vehicle System Dynamics, 56(12):1817–1837. https://doi.org/10.1080/00423114.2018.1439589

Wu XW, Rakheja S, Cai WB, et al., 2019. A study of formation of high order wheel polygonalization. Wear, 424–425:1–14. https://doi.org/10.1016/j.wear.2019.01.099

Wu Y, Du X, Zhang HJ, et al., 2017. Experimental analysis of the mechanism of high-order polygonal wear of wheels of a high-speed train. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 18(8):579–592. https://doi.org/10.1631/jzus.A1600741

Ye YG, Shi DC, Krause P, et al., 2020. Wheel flat can cause or exacerbate wheel polygonization. Vehicle System Dynamics, 58(10):1575–1604. https://doi.org/10.1080/00423114.2019.1636098

Zhang J, Han GX, Xiao XB, et al., 2014. Influence of wheel polygonal wear on interior noise of high-speed trains. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 15(12):1002–1018. https://doi.org/10.1631/jzus.A1400233

Zhao XN, Chen GX, Lv JZ, et al., 2019. Study on the mechanism for the wheel polygonal wear of high-speed trains in terms of the frictional self-excited vibration theory. Wear, 426–427:1820–1827. https://doi.org/10.1016/j.wear.2019.01.020

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (No. 51875484), the Scientific Research Foundation of the State Key Laboratory of Traction Power of Southwest Jiaotong University (No. 2017TPL_T05), and the Opening Project of The State Key Laboratory of Heavy Duty AC Drive Electric Locomotive Systems Integration (No. 2017ZJKF01), China

Contributors

Ze-feng WEN designed the research. Gong-quan TAO and Xiao-long LIU processed the corresponding data. Gong-quan TAO wrote the first draft of the manuscript. Ze-feng WEN and Xue-song JIN helped to organize the manuscript. Gong-quan TAO and Ze-feng WEN revised and edited the final version.

Conflict of interest

Gong-quan TAO, Xiao-long LIU, Ze-feng WEN, and Xue-song JIN declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Tao, Gq., Liu, Xl., Wen, Zf. et al. Formation process, key influencing factors, and countermeasures of high-order polygonal wear of locomotive wheels. J. Zhejiang Univ. Sci. A 22, 70–84 (2021). https://doi.org/10.1631/jzus.A2000081

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A2000081