Abstract

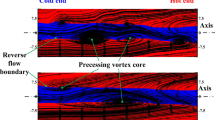

The critical penetration condition is an essential component of studies on the mechanism of sink vortex formation. However, the condition and its transition process are unknown. To address this issue, we constructed a Rankine-vortex-based fluid mechanic model, and proposed a Helmholtz-equation-based solution method to acquire the critical penetration condition. The two-phase mass suction-extraction mechanism of the Ekman boundary layer was discussed. Numerical results show that the critical penetration condition is dependent on the initial velocity components; if the initial disturbances are enhanced, the suction-extraction height and Ekman layer thickness increase. A particle image velocimetry (PIV)-based observation experimental platform was developed, and the effectiveness of the proposed method was verified. The vortex core boundary was observed first, so the radius of the vortex core could be acquired precisely.

中文概要

目的

提出一种自由汇流旋涡形成过程建模求解方法, 得到其临界贯穿条件,并揭示其Ekman 边界层抽 吸演化机理。

创新点

1. 基于二维Rankine 位势涡理论,建立自由汇流 旋涡动力学模型,得到其压力、速度分布;2. 提 出一种基于Helmholtz 方程的汇流旋涡贯穿临界 条件求解方法;3. 成功搭建一种基于双目内窥技 术的汇流旋涡观测实验平台,可实现对旋涡贯穿 及Ekman 抽吸过程的精确观测。

方法

1. 将汇流旋涡定义为涡核与核外流两部分,并基 于Bernoulli 方程与Lamb-ΓΡΟΜΕΚΟ 方程得到汇 流旋涡界面形状及压力、速度分布;2. 基于上述 动力学模型,结合Helmholtz 涡量动力学方程, 利用分离变量积分方法,得到旋涡形成轴向速度 与深度的解析关系表达式;3. 基于粒子图像测速 (PIV)方法,结合双目内窥技术,实现对汇流 旋涡临界贯穿与边界层抽吸的流动细节特征的实 时追踪。

结论

1. 汇流旋涡临界贯穿条件是一个解集,这是由不 同的流场初始扰动条件造成的;2. 旋涡抽吸孔最 低点的高度由容器的几何参数决定,与初始扰动 速度无关;3. 若初始扰动增强,旋涡深度与Ekman 层厚度增加,但在抽吸过程中的边界层涡量强度 有减弱趋势;4. PIV 实验验证了上述理论结果的 正确性,并观测到旋涡半径边界与涡量集聚现象。

Similar content being viewed by others

References

Aboelkassem Y, Georgicis V, 2007. New model for compressible vortices. ASME Journal of Fluids Engineering, 129(8): 1073–1079. https://doi.org/10.1115/1.2746897

Aboelkassem Y, Vatistas GH, Esmail N, 2005. Viscous dissipation of Rankine vortex profile in zero meridional flow. Acta Mechanica Sinica, 21(6): 550–556. https://doi.org/10.1007/s10409–005–0073–3

Andersen A, Bohr T, Stenum B, 2003. Anatomy of a bathtub vortex. Physical Review Letters, 91(10): 104502. https://doi.org/10.1103/PhysRevLett.91.104502

Andersen A, Bohr T, Stenum B, 2006. The bathtub vortex in a rotating container. Journal of Fluid Mechanics, 556: 121–146. https://doi.org/10.1017/S0022112006009463

Basu S, Saha A, Kumar R, 2012. Thermally induced secondary atomization of droplet in an acoustic field. Applied Physics Letters, 100(5): 054101. https://doi.org/10.1063/1.3680257

Chen JL, Xu F, Tan DP, et al., 2015. A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Applied Energy, 141:106–118. https://doi.org/10.1016/j.apenergy.2014.12.026

Chen YC, Huang SL, Li ZY, et al., 2013. A bathtub vortex under the influence of a protruding cylinder in a rotating tank. Journal of Fluid Mechanics, 733:134–157. https://doi.org/10.1017/jfm.2013.441

Chen ST, Tan DP, 2018. A SA–ANN–based modeling method for human cognition mechanism and the PSACO cognition algorithm. Complexit., 2018. 6264124. https://doi.org/10.1155/2018/6264124

Di J, Fu XC, Zheng HJ, et al., 2015. H–TiO2/C/MnO2 nanocomposite materials for high–performance supercapacitors. Journal of Nanoparticle Research, 17(6): 255. https://doi.org/10.1007/s11051–015–3060–z

Ding H, Lv JD, Wu HP, et al., 2018. Enhanced light–harvesting by plasmonic hollow gold nanospheres for photovoltaic performance. Royal Society Open Science, 5(1): 171350. https://doi.org/10.1098/rsos.171350

Dolan SR, Oliveira ES, 2013. Scattering by a draining bathtub vortex. Physical Review D, 87(12): 124038. https://doi.org/10.1103/PhysRevD.87.124038

Ge JQ, Tan DP, Ji SM, 2018. A gas–liquid–solid three–phase abrasive flow processing method based on bubble collapsing. International Journal of Advanced Manufacturing Technology, 95(1–4): 1069–1085. https://doi.org/10.1007/s00170–017–1250–9

Ghani IA, Sidik NAC, Kamaruzaman N, 2017. Hydrothermal performance of microchannel heat sink: the effect of channel design. International Journal of Heat and Mass Transfer, 107:21–44. https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.031

Huang XY, Cheng WJ, Zhong W, et al., 2017. Development of new pressure regulator with flowrate–amplification using vacuum ejector. Vacuum, 144:172–182. https://doi.org/10.1016/j.precisioneng.2018.01.006

Ji SM, Xiao FQ, Tan DP, 2010. Analytical method for softness abrasive flow field based on discrete phase model. Science China–Technological Sciences, 53(10): 2867–2877. https://doi.org/10.1007/s11431–010–4046–9

Ji SM, Weng XX, Tan DP, 2012. Analytical method of softness abrasive two–phase flow field based on 2D model of LSM. Acta Physica Sinica, 61(1): 010205 (in Chinese).

Ji SM, Ge JQ, Tan DP, 2017. Wall contact effects of particlewall collision process in two–phase particle fluid. Journal of Zhejiang University–SCIENCE A (Applied Physics & Engineering), 18(12): 958–973. https://doi.org/10.1631/jzus.A1700039

Li C, Ji SM, Tan DP, 2012. Softness abrasive flow method oriented to tiny scale mold structural surface. International Journal of Advanced Manufacturing Technology, 61(9–12): 975–987. https://doi.org/10.1007/s00170–011–3621–y

Li C, Ji SM, Tan DP, 2013. Multiple–loop digital control method for 400 Hz inverter system based on phase feedback. IEEE Transactions on Power Electronics, 28(1): 408–417. https://doi.org/10.1109/TPEL.2012.2188043

Li HX, Wang Q, Jiang J, et al., 2016. Analysis of factors affecting free surface vortex formation during steel teeming. ISIJ International, 56(1): 94–102. https://doi.org/10.2355/isijinternational.ISIJINT–2015–096

Li J, Ji SM, Tan DP, 2017. Improved soft abrasive flow finishing method based on turbulent kinetic energy enhancing. Chinese Journal of Mechanical Engineering, 30(2): 301–309. https://doi.org/10.1007/s10033–017–0071–y

Li PX, Liu P, Liu ZC, et al., 2017. Experimental and numerical study on the heat transfer and flow performance for the circular tube fitted with drainage inserts. International Journal of Heat and Mass Transfer, 107:686–696. https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.094

Lin R, Yan ZG, Yu JK, 2010. Physical modeling test of vortex during teeming from ladle. Journal of Northeastern University, 31(9): 1287–1291.

Lundgren TS, 1985. The vortical flow above the drain–hole in a rotating vessel. Journal of Fluid Mechanics, 155:381–412. https://doi.org/10.1017/S0022112085001860

Matsumoto Y, Hoshino M, 2004. Onset of turbulence induced by a Kelvin–Helmholtz vortex. Geophysical Research Letters, 31(2): L02807. https://doi.org/10.1029/2003GL018195

Nguyen T, Liu D, Thongkaew K, et al., 2018. The wear mechanisms of reaction bonded silicon carbide under abrasive polishing and slurry jet impact conditions. Wear, 410–411:156–164. https://doi.org/10.1016/j.wear.2018.06.001

Peterson SD, Porfiri M, 2012. Energy exchange between a vortex ring and an ionic polymer metal composite. Applied Physics Letters, 100(11): 114102. https://doi.org/10.1063/1.3693184

Qi H, Xie Z, Hong T, et al., 2017. CFD modelling of a novel hydrodynamic suspension polishing process for ultrasmooth surface with low residual stress. Powder Technology, 317:320–328. https://doi.org/10.1016/j.powtec.2017.05.030

Qi H, Cheng Z, Cai D, et al., 2018. Experimental study on the improvement of surface integrity of tungsten steel using acoustic levitation polishing. Journal of Materials Processing Technology, 259:361–367. https://doi.org/10.1016/j.jmatprotec.2018.04.043

Shi KG, Liu X, 2018. Experimental and theoretical study of dynamic characteristics of Bernoulli gripper. Precision Engineering, 52:323–331. https://doi.org/10.1016/j.precisioneng.2018.01.006

Shi YX, Fox RO, Olsen MG, 2011. Confocal imaging of laminar and turbulent mixing in a microscale multi–inlet vortex nanoprecipitation reactor. Applied Physics Letters, 99(20): 204103. https://doi.org/10.1063/1.3662042

Tan DP, Zhang LB, 2014. A WP–based nonlinear vibration sensing method for invisible liquid steel slag detection. Sensors and Actuators B–Chemical, 202:1257–1269. https://doi.org/10.1016/j.snb.2014.06.014

Tan DP, Li PY, Pan XH, 2009. Application of improved HMM algorithm in slag detection system. Journal of Iron and Steel Research International, 16(1): 1–6. https://doi.org/10.1016/S1006–706X(09)60001–7

Tan DP, Ji SM, Li PY, et al., 2010. Development of vibration style ladle slag detection method and the key technologies. Science China–Technological Sciences, 53(9): 2378–2387. https://doi.org/10.1007/s11431–010–4073–6

Tan DP, Li PY, Ji YX, et al., 2013. SA–ANN–based slag carryover detection method and the embedded WME platform. IEEE Transactions on Industrial Electronics, 60(10): 4702–4713. https://doi.org/10.1109/TIE.2012.2213559

Tan DP, Zhang LB, Ai QL, 2016a. An embedded self–adapting network service framework for networked manufacturing system. Journal Intelligent Manufacturing, p.1–18. https://doi.org/10.1007/s10845–016–1265–3

Tan DP, Yang T, Zhao J, et al., 2016b. Free sink vortex Ekman suction–extraction evolution mechanism. Acta Physica Sinica, 65(5): 054701. https://doi.org/10.7498/aps.65.054701

Tan DP, Ji SM, Fu YZ, 2016c. An improved soft abrasive flow finishing method based on fluid collision theory. International Journal of Advanced Manufacturing Technology, 85(5–8): 1261–1274. https://doi.org/10.1007/s00170–015–8044–8

Tan DP, Li L, Zhu YL, et al., 2017a. An embedded cloud database service method for distributed industry monitoring. IEEE Transactions on Industrial Informatics, 14(7): 2881–2893. https://doi.org/10.1109/TII.2017.2773644

Tan DP, Chen ST, Bao GJ, et al., 2017b. An embedded lightweight GUI component library and the ergonomics optimization method for industry process monitoring. Frontiers of Information Technology & Electronic Engineering, 19(5): 604–625. https://doi.org/10.1631/FITEE.1601660

Tan DP, Ni YS, Zhang LB, 2017c. Two–phase sink vortex suction mechanism and penetration dynamic characteristics in ladle teeming process. Journal of Iron and Steel Research International, 24(7): 669–677. https://doi.org/10.1016/S1006–706X(17)30101–2

Tong SP, 2006. Advanced Fluid Mechanics. China University of Petroleum Press, Dongying, China, p.155 (in Chinese).

Turkyilmazoglu M, 2011. Wall stretching in magnetohydrodynamics rotating flows in inertial and rotating frames. Journal of Thermophysics and Heat Transfer, 25(4): 606–613. https://doi.org/10.2514/1.T3750

Turkyilmazoglu M, 2018. Flow and heat due to a surface formed by a vortical source. European Journal of Mechanics B–Fluids, 68:76–84. https://doi.org/10.1016/j.euromechflu.2017.11.010

Tyvand PA, Haugena KB, 2005. An impulsive bathtub vortex. Physics of Fluids, 17:062105. https://doi.org/10.1063/1.1938216

Wang XH, Liu AP, Xing Y, et al., 2018. Three–dimensional graphene biointerface with extremely high sensitivity to single cancer cell monitoring. Biosensors & Bioelectronics, 105:22–28. https://doi.org/10.1016/j.bios.2018.01.012

Wu HP, Li L, Chai GZ, et al., 2016. Three–dimensional thermal weight function method for the interface crack problems in bimaterial structures under a transient thermal loading. Journal of Thermal Stresses, 39(4): 371–385. https://doi.org/10.1080/01495739.2016.1152108

Wu ZH, Zheng NG, Zhang SW, et al., 2016. Maze learning by a hybrid brain–computer system. Scientific Reports, 6: 31746. https://doi.org/10.1038/srep31746

Yokoyama N, Maruyama Y, Mizushima J, 2012. Origin of the bathtub vortex and its formation mechanism. Journal of the Physical Society of Japan, 81(7): 074401. https://doi.org/10.1143/JPSJ.81.074401

Zeng X, Ji SM, Tan DP, et al., 2013. Softness consolidation abrasives material removal characteristic oriented to laser hardening surface. International Journal of Advanced Manufacturing Technology, 69(9–12): 2323–2332. https://doi.org/10.1007/s00170–013–4985–y

Zeng X, Ji SM, Jin MS, et al., 2014. Investigation on machining characteristic of pneumatic wheel based on softness consolidation abrasives. International Journal of Precision Engineering and Manufacturing, 15(10): 2031–2039. https://doi.org/10.1007/s12541–014–0560–1

Zeng X, Ji SM, Jin MS, et al., 2016. Research on dynamic characteristic of softness consolidation abrasives in machining process. International Journal of Advanced Manufacturing Technology, 82(5–8): 1115–1125. https://doi.org/10.1007/s00170–015–7392–8

Zhang L, Wang JS, Tan DP, et al., 2017. Gas compensation based abrasive flow processing method for complex titanium alloy surfaces. International Journal of Advanced Manufacturing Technology, 92(9–12): 3385–3397. https://doi.org/10.1007/s00170–017–0400–4

Zhang L, Yuan Z, Qi Z, et al., 2018a. CFD–based study of the abrasive flow characteristics within constrained flow passage in polishing of complex titanium alloy surfaces. Powder Technology, 333:209–218. https://doi.org/10.1016/j.powtec.2018.04.046

Zhang L, Yuan Z, Tan DP, et al., 2018b. An improved abrasive flow processing method for complex geometric surfaces of titanium alloy artificial joints. Applied Sciences, 8(7): 1037. https://doi.org/10.3390/app8071037

Zhang LB, Lv HP, Tan DP, et al., 2018. An adaptive quantum genetic algorithm for task sequence planning of complex assembly systems. Electronics Letters, 54(14): 870–872. https://doi.org/10.1049/el.2018.0609

Zhao JH, Li X, 2016. Effect of supply flow rate on performance of pneumatic non–contact gripper using vortex flow. Experimental Thermal and Fluid Science, 79:91–100. https://doi.org/10.1016/j.expthermflusci.2016.06.020

Zhao ZF, Zhou H, Zheng LX, et al., 2017. Molecules interface engineering derived external electric field for effective charge separation in photoelectrocatalysis. Nano Energy, 42:90–97. https://doi.org/10.1007/s00170–015–7392–8

Zheng HJ, Wang JX, Jia Y, et al., 2012. In–situ synthetize multi–walled carbon nanotubes@MnO2 nanoflake coreshell structured materials for supercapacitors. Journal of Power Sources, 216:508–514. https://doi.org/10.1016/j.jpowsour.2012.06.047

Zheng HJ, Niu P, Zhao ZF, 2017. Carbon quantum dot sensitized Pt@Bi2WO6/FTO electrodes for enhanced photoelectro–catalytic activity of methanol oxidation. RCS Advances, 7(43): 26943–26951. https://doi.org/10.1039/c7ra01867c

Zheng NG, Su LJ, Zhang DQ, et al., 2015. A computational model for ratbot locomotion based on cyborg intelligence. Neurocomputing, 170:92–97. https://doi.org/10.1016/j.neucom.2014.12.115

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (No. 51775501) and the Zhejiang Provincial Natural Science Foundation of China (No. LR16E050001)

Rights and permissions

About this article

Cite this article

Tan, Dp., Li, L., Zhu, Yl. et al. Critical penetration condition and Ekman suction-extraction mechanism of a sink vortex. J. Zhejiang Univ. Sci. A 20, 61–72 (2019). https://doi.org/10.1631/jzus.A1800260

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A1800260