Abstract

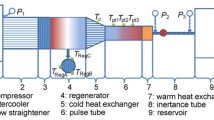

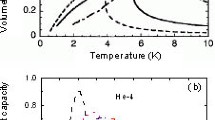

A Stirling-type pulse tube cryocooler (PTC) with precooling was designed and manufactured to investigate its performance at 4 K. Numerical simulation was carried out based on the well-known regenerator model REGEN with an emphasis on the performance of a 4 K stage regenerator of the Stirling-type PTC as influenced by the warm end temperature, pressure ratio, frequency and average pressure with helium-4 and helium-3 as the working fluid respectively. This study demonstrates that the use of a cold inertance tube can significantly improve the efficiency of a 4 K Stirling-type PTC. A preliminary experimental investigation was carried out with helium-4 as the working fluid and a refrigeration temperature of 4.23 K was achieved. The experimental results show that the operating frequency has a significant influence on the performance of the Stirling-type PTC and a relatively low average pressure is favorable for decreasing the loss associated with the real gas effects of a 4 K Stirling-type PTC.

Similar content being viewed by others

References

Dai, L., Gan, Z.H., Qiu, L.M., Zhang, X.B., Zhang, X.J., 2007. Design of 30 Hz regenerator operating at liquid helium temperatures. Cryogenic Engineering, suppl:194–199 (in Chinese).

Gan, Z.H., Liu, G.J., Wu, Y.Z., Cao, Q., Qiu, L.M., Chen, G.B., Pfotenhauer, J.M., 2008. Study on a 5.0 W/80 K single stage Stirling type pulse tube cryocooler. Journal of Zhejiang University SCIENCE A, 9(9):1277–1282. [doi:10.1631/jzus.A0820220]

Gan, Z.H., Dong, W.Q., Qiu, L.M., Zhang, X.B., Sun, H., He, Y.L., Radebaugh, R., 2009. A single-stage GM-type pulse tube cryocooler operating at 10.6 K. Cryogenics, 49(5):198–201. [doi:10.1016/j.cryogenics.2009.01.004]

Huang, Y.H., Chen, G.B., Arp, V.D., 2006. Equation of state for fluid helium-3 based on Debye phonon model. Applied Physics Letters, 88(9):091905. [doi:10.1063/1.2178867]

Jiang, N., Lindemann, F., Giebeler, F., Thummes, G., 2004. A 3He pulse tube cooler operating down to 1.3 K. Cryogenics, 44(11):809–816. [doi:10.1016/j.cryogenics.2004.05.003]

Nast, T., Olson, J., Champagne, P., Evtimov, B., Frank, D., Roth, E., Renna, T., 2006. Overview of Lockheed Martin cryocoolers. Cryogenics, 46(2–3):164–168. [doi:10.1016/j.cryogenics.2005.12.006]

Nast, T., Olson, J., Roth, E., Evtimov, B., Frank, D., Champagne, P., 2007. Development of Remote Cooling Systems for Low-temperature, Space-borne Systems. Cryocoolers 14th International Cryocooler Conference, CO, USA, p.33–40.

Nast, T., Olson, J., Champagne, P., Mix, J., Evtimov, B., Roth, E., Collaco, A., 2008. Development of a 4.5 K Pulse Tube Cryocooler for Superconducting Electronics. Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 53:881–886. [doi:10.1063/1.2908684]

Olson, J., Champagne, P., Roth, E., Evtimov, B., Clappier, R., Nast, T., Renna, T., Martin, B., 2005. Lockheed Martin 6 K/18 K Cryocooler. Cryocoolers 13th Springer Science & Business Media, NY, USA, p.25–30. [doi:10.1007/0-387-27533-9_4]

Olson, J.R., Moore, M., Champagne, P., Roth, E., Evtimov, B., Jensen, J., Collaco, A., Nast, T., 2006. Development of a Space-type 4-stage Pulse Tube Cryocooler for Very Low Temperature. Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 51:623–631. [doi:10.1063/1.2202468]

Qiu, L.M., He, Y.L., Gan, Z.H, Wang, L.H., Chen, G.B., 2005. A separate two-stage pulse tube cooler working at liquid Helium temperature. Chinese Science Bulletin, 50(10):1030–1033. [doi:10.1360/982005-187]

Qiu, L.M., Li, Z.P., Gan, Z.H., Dai, L., 2008. Design of a 4 K Single-stage Stirling Type Pulse Tube Cooler Precooled by a G-M Type Pulse Tube Cooler. International Conference on Cryogenics and Refrigeration, Beijing, China, p.313–316.

Radebaugh, R., O’Gallagher, A., 2006. Regenerator Operation at Very High Frequencies for Micro-cryocoolers. Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 51:1919–1928. [doi:10.1063/1.2202623]

Radebaugh, R., O’Gallagher, A., Gary, J., 2002. Regenerator Behavior at 4 K: Effect of Volume and Porosity. Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 47:961–968. [doi:10.1063/1.1472117]

Radebaugh, R., Lewis, M., Luo, E.C., Pfotenhauer, J.M., Nellis, G.F., Schunk, L.A., 2006. Inertance Tube Optimization for Pulse Tube Refrigerators. Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 51:59–67. [doi:10.1063/1.2202401]

Radebaugh, R., Huang, Y.H., O’Gallagher, A., Gary, J., 2008. Calculated Regenerator Performance at 4 K with Helium-4 and Helium-3. Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 53:225–234. [doi:10.1063/1.2908551]

Radebaugh, R., Huang, Y., O’Gallagher, A., Gary, J., 2009. Calculated Performance of Low-porosity Regenerators at 4 K with He-4 and He-3. Cryocoolers 15th International Cryocooler Conference, CO, USA, p.325–334.

Ross, R.G.Jr., 2005. A Study of the Use of 6 K ACTDP Cryocoolers for the MIRI Instrument on JWST. Cryocoolers 13th Springer Science & Business Media, NY, USA, p.15–24. [doi:10.1007/0-387-27533-9_3]

Ross, R.G.Jr., Boyle, R.F., 2003. NASA Space Cryocooler Programs—An Overview. Cryocoolers 12, Kluwer Academic/Plenum Publishers, NY, USA, p.1–8. [doi:10.1007/0-306-47919-2_1]

Ross, R.G.Jr., Johnson, D.L., 2006. NASA’s Advanced Cryocooler Technology Development Program (ACTDP). Advances in Cryogenic Engineering, American Institute of Physics, NY, USA, 51:607–614. [doi:10.1063/1.2202466]

Ross, R.G.Jr., Boyle, R.F., 2007. An Overview of NASA Space Cryocooler Programs-2006. Cryocoolers 14th International Cryocooler Conference, CO, USA, p.1–10.

Webber, R.J., Dotsenko, V.V., Delmas, J., Kadin, A.M., Track, E.K., 2009. Evaluation of a 4 K 4-stage Pulse Tube Cryocooler for Superconducting Electronics. Cryocoolers 15th International Cryocooler Conference, CO, USA, p.657–664.

Xu, M.Y., de Waele, A.T.A.M., Ju, Y.L., 1999. A pulse tube refrigerator below 2 K. Cryogenics, 39(10):865–869. [doi:10.1016/S0011-2275(99)00101-0]

Author information

Authors and Affiliations

Corresponding author

Additional information

Project (No. 50676081) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Gan, Zh., Li, Zp., Chen, J. et al. Design and preliminary experimental investigation of a 4 K Stirling-type pulse tube cryocooler with precooling. J. Zhejiang Univ. Sci. A 10, 1277–1284 (2009). https://doi.org/10.1631/jzus.A0920095

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A0920095