Abstract

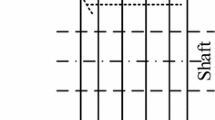

In this study, we investigated the torque characteristics of large low-speed direct-drive permanent magnet synchronous generators with stator radial ventilating air ducts for offshore wind power applications. Magnet shape optimization was used first to improve the torque characteristics using two-dimensional finite element analysis (FEA) in a permanent magnet synchronous generator with a common stator. The rotor step skewing technique was then employed to suppress the impacts of mechanical tolerances and defects, which further improved the torque quality of the machine. Comprehensive three-dimensional FEA was used to evaluate accurately the overall effects of stator radial ventilating air ducts and rotor step skewing on torque features. The influences of the radial ventilating ducts in the stator on torque characteristics, such as torque pulsation and average torque in the machine with and without rotor step skewing techniques, were comprehensively investigated using three-dimensional FEA. The results showed that stator radial ventilating air ducts could not only reduce the average torque but also increase the torque ripple in the machine. Furthermore, the torque ripple of the machine under certain load conditions may even be increased by rotor step skewing despite a reduction in cogging torque.

Similar content being viewed by others

References

Ashabani, M., Mohamed, Y.A.R.I., 2011. Multiobjective shape optimization of segmented pole permanentmagnet synchronous machines with improved torque characteristics. IEEE Trans. Magn., 47(4):795–804. http://dx.doi.org/10.1109/TMAG.2010.2104327

Atallah, K., Wang, J., Howe, D., 2003. Torque-ripple minimization in modular permanent-magnet brushless machines. IEEE Trans. Ind. Appl., 39(6):1689–1695. http://dx.doi.org/10.1109/TIA.2003.818986

Bianchi, N., Bolognani, S., 2002. Design techniques for reducing the cogging torque in surface-mounted PM motors. IEEE Trans. Ind. Appl., 38(5):1259–1265. http://dx.doi.org/10.1109/TIA.2002.802989

Boukais, B., Zeroug, H., 2010. Magnet segmentation for commutation torque ripple reduction in a brushless DC motor drive. IEEE Trans. Magn., 46(11):3909–3919. http://dx.doi.org/10.1109/TMAG.2010.2057439

Chen, H.S., Dorrell, D.G., Tsai, M.C., 2010. Design and operation of interior permanent-magnet motors with two axial segments and high rotor saliency. IEEE Trans. Magn., 46(9):3664–3675. http://dx.doi.org/10.1109/TMAG.2010.2048037

Chen, N.N., Ho, S.L., Fu, W.N., 2010. Optimization of permanent magnet surface shapes of electric motors for minimization of cogging torque using FEM. IEEE Trans. Magn., 46(6):2478–2481. http://dx.doi.org/10.1109/TMAG.2010.2044764

Chu, W.Q., Zhu, Z.Q., 2013. Reduction of on-load torque ripples in permanent magnet synchronous machines by improved skewing. IEEE Trans. Magn., 49(7):3822–3825. http://dx.doi.org/10.1109/TMAG.2013.2247381

Fei, W.Z., Luk, P.C.K., 2009. An improved model for the back-EMF and cogging torque characteristics of a novel axial flux permanent magnet synchronous machine with a segmental laminated stator. IEEE Trans. Magn., 45(10):4609–4612. http://dx.doi.org/10.1109/TMAG.2009.2024127

Fei, W.Z., Luk, P.C.K., 2010. A new technique of cogging torque suppression in direct-drive permanent-magnet brushless machines. IEEE Trans. Ind. Appl., 46(4):1332–1340. http://dx.doi.org/10.1109/TIA.2010.2049551

Fei, W.Z., Luk, P.C.K., 2012. Torque ripple reduction of a direct-drive permanent-magnet synchronous machine by material-efficient axial pole pairing. IEEE Trans. Ind. Electron., 59(6):2601–2611. http://dx.doi.org/10.1109/TIE.2011.2158048

Fei, W.Z., Luk, P.C.K., Shen, J.X., 2012. Torque analysis of permanent-magnet flux switching machines with rotor step skewing. IEEE Trans. Magn., 48(10):2664–2673. http://dx.doi.org/10.1109/TMAG.2012.2198223

Fei, W.Z., Luk, P.C.K., Wu, D., et al., 2013. Approximate three-dimensional finite element analysis of large permanent magnet synchronous generators with stator radial ventilating ducts. 39th Annual Conf. of IEEE Industrial Electronics Society, p.7313–7318. http://dx.doi.org/10.1109/IECON.2013.6700349

Güemes, J.A., Iraolagoitia, A.A., Del Hoyo, J.I., et al., 2011. Torque analysis in permanent-magnet synchronous motors: a comparative study. IEEE Trans. Energy Conv., 26(1):55–63. http://dx.doi.org/10.1109/TEC.2010.2053374

Han, S.H., Jahns, T.M., Soong, W.L., et al., 2010. Torque ripple reduction in interior permanent magnet synchronous machines using stators with odd number of slots per pole pair. IEEE Trans. Energy Conv., 25(1):118–127. http://dx.doi.org/10.1109/TEC.2009.2033196

Islam, M.S., Mir, S., Sebastian, T., et al., 2005. Design consideration of sinusoidally excited permanent-magnet machines for low-torque-ripple applications. IEEE Trans. Ind. Appl., 41(4):955–962. http://dx.doi.org/10.1109/TIA.2005.851026

Islam, R., Husain, I., Fardoun, A., et al., 2009. Permanentmagnet synchronous motor magnet designs with skewing for torque ripple and cogging torque reduction. IEEE Trans. Ind. Appl., 45(1):152–160. http://dx.doi.org/10.1109/TIA.2008.2009653

Jahns, T.M., Soong, W.L., 1996. Pulsating torque minimization techniques for permanent magnet AC motor drives—a review. IEEE Trans. Ind. Electron., 43(2):321–330. http://dx.doi.org/10.1109/41.491356

Lateb, R., Takorabet, N., Meibody-Tabar, F., 2006. Effect of magnet segmentation on the cogging torque in surface-mounted permanent-magnet motors. IEEE Trans. Magn., 42(3):442–445. http://dx.doi.org/10.1109/TMAG.2005.862756

Li, T., Slemon, G., 1988. Reduction of cogging torque in permanent magnet motors. IEEE Trans. Magn., 24(6):2901–2903. http://dx.doi.org/10.1109/20.92282

Pang, Y., Zhu, Z.Q., Howe, D., 2005. Self-shielding magnetized vs. shaped parallel-magnetized PM brushless AC motors. KIEE Int. Trans. Electr. Mach. Energy Conv. Syst., 5-B(1):13–19.

Pyrhonen, J., Ruuskanen, V., Nerg, J., et al., 2010. Permanent-magnet length effects in AC machines. IEEE Trans. Magn., 46(10):3783–3789. http://dx.doi.org/10.1109/TMAG.2010.2050002

Ruuskanen, V., Nerg, J., Pyrhonen, J., 2011. Effect of lamination stack ends and radial cooling channels on noload voltage and inductances of permanent-magnet synchronous machines. IEEE Trans. Magn., 47(11):4643–4649. http://dx.doi.org/10.1109/TMAG.2011.2158233

Ruuskanen, V., Nerg, J., Niemelä, M., et al., 2013. Effect of radial cooling ducts on the electromagnetic performance of the permanent magnet synchronous generators with double radial forced air cooling for direct-driven wind turbines. IEEE Trans. Magn., 49(6):2974–2981. http://dx.doi.org/10.1109/TMAG.2013.2238679

Sopanen, J., Ruuskanen, V., Nerg, J., et al., 2011. Dynamic torque analysis of a wind turbine drive train including a direct-driven permanent-magnet generator. IEEE Trans. Ind. Electron., 58(9):3859–3867. http://dx.doi.org/10.1109/TIE.2010.2087301

Tapia, J.A., Pyrhonen, J., Puranen, J., et al., 2013. Optimal design of large permanent magnet synchronous generators. IEEE Trans. Magn., 49(1):642–650. http://dx.doi.org/10.1109/TMAG.2012.2207907

Wang, Y., Jin, M.J., Fei, W.Z., et al., 2010. Cogging torque reduction in permanent magnet flux-switching machines by rotor teeth axial pairing. IET Electr. Power Appl., 4(7):500–506. http://dx.doi.org/10.1049/iet-epa.2009.0205

Yang, Y., Wang, X., Zhang, R., et al., 2006. The optimization of pole arc coefficient to reduce cogging torque in surface-mounted permanent magnet motors. IEEE Trans. Magn., 42(4):1135–1138. http://dx.doi.org/10.1109/TMAG.2006.871452

Zhu, Z.Q., Howe, D., 2000. Influence of design parameters on cogging torque in permanent magnet machines. IEEE Trans. Energy Conv., 15(4):407–412. http://dx.doi.org/10.1109/60.900501

Zhu, Z.Q., Ruangsinchaiwanich, S., Ishak, D., et al., 2005. Analysis of cogging torque in brushless machines having nonuniformly distributed stator slots and stepped rotor magnets. IEEE Trans. Magn., 41(10):3910–3912. http://dx.doi.org/10.1109/TMAG.2005.854968

Author information

Authors and Affiliations

Corresponding author

Additional information

Project supported by the National Natural Science Foundation of China (No. 51377140) and the National Basic Research Program (973) of China (No. 2013CB035604)

ORCID: He HAO, http://orcid.org/0000-0001-6376-9106

Rights and permissions

About this article

Cite this article

Hao, H., Fei, Wz., Miao, Dm. et al. Torque characteristics in a large permanent magnet synchronous generator with stator radial ventilating air ducts. Frontiers Inf Technol Electronic Eng 17, 814–824 (2016). https://doi.org/10.1631/FITEE.1500238

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/FITEE.1500238

Keywords

- Permanent magnet synchronous generator (PMSG)

- Radial ventilating air duct

- Torque ripple

- Step skewing

- Magnet shape optimization

- Finite element analysis

- Wind power