Abstract

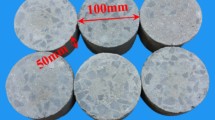

In this work, findings of a numerical study performed to investigate the impact behavior of porous concrete, modeled as a four phase cementitious composite consisting of aggregates, cement paste, interfacial transition zones (ITZ) and air, are presented. The numerical analyses contributed to the process of designing a special type of concrete for safety purposes i.e. as a protective building material to be used in safety walls outside important buildings or munition magazines for storing explosives. In case of an explosion, large concrete fragments that are formed, cause a very important threat. Therefore, in the scope of a research project, designing a special type of concrete having sufficient strength, but fracturing into small fragments under impact loading was aimed. In the numerical analyses, model porous concretes, in which the amounts and properties of pores and aggregates could be varied individually, were used to see the sole effect of each parameter. According to the results, it was found that at constant total porosity, the impact strength increased with decreasing pore size while multiple fragmentation was observed. On the other hand, the impact strengths of porous concretes with different size aggregates (with constant total aggregate content and porosity) were approximately the same when no ITZ was defined. However, when ITZ was present, the impact strength was found to decrease as the aggregates were finer. This trend was also valid for the respective full concretes. Representative experimental results of porous concretes were also presented in order to support the numerical results.

Similar content being viewed by others

References

Dong H, Gao P, Ye G (2017) Characterization and comparison of capillary pore structures of digital cement pastes. Mater Struct 50(2):154. https://doi.org/10.1617/s11527-017-1023-9

Chen G, Hao Y, Hao H (2015) 3D meso-scale modelling of concrete material in spall tests. Mater Struct 48:1887–1899. https://doi.org/10.1617/s11527-014-0281-z

Agar Ozbek AS, Weerheijm J, Schlangen E, van Breugel K (2013) Dynamic behavior of porous concretes under drop weight impact testing. Cem Concr Compos 39:1–11. https://doi.org/10.1016/j.cemconcomp.2013.03.012

Agar Ozbek AS (2016) Design and analyses of porous concrete for safety applications. Dissertation, Delft University of Technology

Chandrappa AK, Biligiri KP (2016) Pervious concrete as a sustainable pavement material-research findings and future prospects: a state-of-the-art review. Constr Build Mater 111:262–274. https://doi.org/10.1016/j.conbuildmat.2016.02.054

Lund MSM, Kevern JT, Schaefer VR, Hansen KK (2017) Mix design for improved strength and freeze-thaw durability of pervious concrete fill in pearl-chain bridges. Mater Struct 50:42. https://doi.org/10.1617/s11527-016-0907-4

Sumanasooriya MS, Neithalath N (2011) Pore structure features of pervious concretes proportioned for desired porosities and their performance prediction. Cem Concr Compos 33:778–787. https://doi.org/10.1016/j.cemconcomp.2011.06.002

Ghafoori N, Dutta S (1995) Building and nonpavement applications of no-fines concrete. J Mater Civ Eng 7(4):286–289. https://doi.org/10.1061/(ASCE)0899-1561(1995)7:4(286)

Timoshenko S, Goodier JN (1987) Theory of elasticity. McGraw Hill, New York

Green DJ (1998) An introduction to the mechanical properties of ceramics. Cambridge University Press, Cambridge

Wong RHC, Lin P, Tang CA (2006) Experimental and numerical study on splitting failure of brittle solids containing single pore under uniaxial compression. Mech Mater 38(2006):142–159. https://doi.org/10.1016/j.mechmat.2005.05.017

Wang Y, Wang Z, Liang Y, Du X, Shi Y (2016) Study on the stress and failure strength around the hole in point supported glass panels. Mater Struct 49:4375–4387. https://doi.org/10.1617/s11527-016-0794-8

Sammis CG, Ashby MF (1986) The failure of brittle porous solids under compressive stress states. Acta Metall 34(3):511–526. https://doi.org/10.1016/0001-6160(86)90087-8

Tang CA, Wong RHC, Chau KT, Lin P (2005) Modeling of compression-induced splitting failure in heterogeneous brittle porous solids. Eng Fract Mech 72:597–615. https://doi.org/10.1016/j.engfracmech.2004.04.008

Zhao C, Matsuda H, Morita C, Shen MR (2011) Study on failure characteristic of rock-like materials with an open-hole under uniaxial compression, strain. Int J Exp Mech 47(5):405–413. https://doi.org/10.1111/j.1475-1305.2009.00701.x

Ashby MF, Sammis CG (1990) The Damage mechanics of brittle solids in compression. Pure Appl Geophys 133(3):489–521

Leguillon D, Piat R (2006) Fracture of porous materials—influence of the pore size. Eng Fract Mech 75(7):1840–1853. https://doi.org/10.1016/j.engfracmech.2006.12.002

Susila E, Hryciw RD (2003) Large displacement FEM modelling of the cone penetration test (CPT) in normally consolidated sand. Int J Numer Anal Meth Geomech 27(7):585–602. https://doi.org/10.1002/nag.287

Wu SR, Gu L (2012) Introduction to the explicit finite element method for nonlinear transient dynamics. Wiley, Hoboken

De Borst R, Crisfield MA, Remmers JJC, Verhoosel CV (2012) Non-linear finite element analysis of solids and structures, 2nd edn. Wiley, West Sussex

Simulia_1 (2013) ABAQUS analysis user’s manual 6.13

Lubliner J, Oliver J, Oller S, Oñate E (1989) A plastic-damage model for concrete. Int J Sol Struct 25(3):229–326. https://doi.org/10.1016/0020-7683(89)90050-4

Lee J, Fenves GL (1998) A plastic damage model for cyclic loading of concrete structures. ASCE J Eng Mech 124:892–900. https://doi.org/10.1061/(ASCE)0733-9399(1998)124:8(892)

Hillerborg A, Modeer M, Petersson PE (1976) Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concr Res 6(1976):773–782. https://doi.org/10.1016/0008-8846(76)90007-7

Chaudhari SV, Chakrabarti MA (2012) Modeling of concrete for nonlinear analysis using finite element code ABAQUS. Int J Comp Appl 44(7):14–18. https://doi.org/10.5120/6274-8437

Jankowiak T, Lodygowski T (2005) Identification of parameters of concrete damage plasticity constitutive model. Found Civ Environ Eng 6:53–69

Kmiecik P, Kaminski M (2011) Modelling of reinforced concrete structures and composite structures with concrete strength degradation taken into consideration. Arch Civ Mech Eng 11(3):623–636. https://doi.org/10.1016/S1644-9665(12)60105-8

Sun JS, Lee KH, Lee PH (2000) Comparison of implicit and explicit finite element methods for dynamic problems. J Mater Process Technol 105(1–2):110–118. https://doi.org/10.1016/S0924-0136(00)00580-X

Martin O (2010) Comparison of different constitutive models for concrete in ABAQUS/explicit for missile impact analyses, JRC European Commission

Rousakis TC, Karabinis AI, Kiousis PD (2007) FRP-confined concrete members: axial compression experiments and plasticity modeling. Eng Struct 29:1343–1353

Chen WF, Han DJ (1988) Plasticity for structural engineers. Springer, New York

Gorst NJS, Williamson SJ, Pallett PF, Clark LA (2003) Friction in temporary works, research report, University of Birmingham, U.K

Deutsches Institut für Normung (1982) Falsework calculation, design and construction DIN 4421:1982. Beuth Veriag GmbH, Berlin

British Standards Institution (1997) Falsework performance requirements and general design, Draft prEN 12812, London, U.K

van Mier JGM (2013) Concrete fracture: a multiscale approach. CRC Press, Boca Raton

Schulson M, Iliescu D, Renshaw CE (1999) On the initiation of shear faults during brittle compressive failure: a new mechanism. J Geophys Res 104:695–705. https://doi.org/10.1029/1998JB900017

Chindaprasirt P, Hatanaka S, Mishima N, Yuasa Y, Chareerat T (2009) Effects of binder strength and aggregate size on the compressive strength and void ratio of porous concrete. Int J Miner Metall Mater 16(6):714–719. https://doi.org/10.1016/S1674-4799(10)60018-0

Deo O, Neithalath N (2010) Compressive behavior of pervious concretes and a quantification of the influence of random pore structure features. Mater Sci Eng A 528(1):402–412. https://doi.org/10.1016/j.msea.2010.09.024

Acknowledgements

The research presented in this work was conducted at Delft University of Technology and supported by the Netherlands Defense Academy and TNO Defense, Security and Safety.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Agar Ozbek, A.S., Weerheijm, J. & van Breugel, K. Impact behavior of model porous concretes. Mater Struct 52, 90 (2019). https://doi.org/10.1617/s11527-019-1388-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-019-1388-z