Abstract

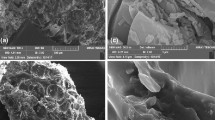

In this study, the effect of aggregates impregnated with phase change material (paraffin type) on properties of concrete is investigated. The experimental series consists of two stages. The first stage is to investigate the techniques used to impregnate phase changed material (paraffin type) into lightweight aggregates and the properties of aggregates with paraffin inside (PLA). Two impregnation techniques are introduced, (1) heat only and (2) heat and pressure (autoclaving). Using the obtained results, the aggregate with the highest level of impregnation in the shortest time is selected to use in the concrete production process of the next stage. In the second stage, the properties of concrete mixed with non-paraffin and paraffin impregnated lightweight aggregates (PLA) at different proportions are investigated. The experimental series include density and absorption, compressive strength, thermal storage (and insulation) and sound transmission loss. Results in aggregate level show the increase in specific gravity and the decrease in absorption with paraffin inserted into aggregates. In concrete form, the density, compressive strength and sound insulation are found to increase with the PLA replacement ratio. The sound transmission loss, on the other hand, becomes less efficient with increasing PLA replacement ratio.

Similar content being viewed by others

References

Abhat A (1983) Low temperature latent heat thermal energy storage, heat storage materials. Sol Energy 30:313–332

Lorsch HG, Kauffman KW, Denton JC (1976) Thermal energy storage for heating and air conditioning, future energy production system. Heat Mass Transf Process 1:69–85

Abhat A et al (1981) Development of a modular heat exchanger with an integrated latent heat storage, Report no. BMFT FBT 81-050, Germany Ministry of Science and Technology Bonn

Hale DV, Hoover MJ, O’Neill MJ (1971) Phase change materials hand book. Marshal Space Flight Center, Alabaa

Sharma A, Tyagi V, Chen CR, Buddhi D (2009) Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev 12:318–345

Sharma A, Tyagi VV, Chen CR, Buddhi D (2009) Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev 13:318–345

George A (1989) Hand book of thermal design. In: Guyer C (ed) Phase change thermal storage materials. McGraw Hill Book Co., New York [chapter 1]

Tyagi VV, Kaushik SC, Tyagi SK, Akiyama T (2011) Development of phase change materials based microencapsulated technology for buildings: a review. Renew Sustain Energy Rev 15:1373–1391

Cabeza LF, Castellon C, Nogues M, Medrano M, Leppers R, Zubillaga O (2007) Use of microencapsulated PCM in concrete walls for energy savings. Energy Build 39:113–119

Boh B, Sumiga B (2008) Microencapsulation technology and its applications in building construction materials. RMZ—Mater Geoenviron 55(3):329–344

Hawlader MNA, Uddin MS, Khin MM (2003) Microencapsulated PCM thermal energy storage system. Appl Energy 74:195–202

Ling T-C, Poon C-S (2013) Use of phase change materials for thermal energy storage in concrete: an overview. Constr Build Mater 46:55–62

Acknowledgments

Authors would like to thank TEKA© Co., Ltd. for supporting lightweight aggregates, all senior students involved in this project and Charissa S. for reviewing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sukontasukkul, P., Intawong, E., Preemanoch, P. et al. Use of paraffin impregnated lightweight aggregates to improve thermal properties of concrete panels. Mater Struct 49, 1793–1803 (2016). https://doi.org/10.1617/s11527-015-0612-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0612-8