Abstract

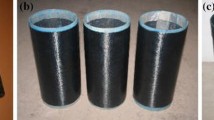

This paper presents the findings of an experimental investigation on the effect of overlap configuration on carbon fiber-reinforced polymer (CFRP)-confined normal- and high-strength concrete. A total of 33 specimens were prepared and tested under monotonic axial compression. All specimens were cylinders with 152 mm diameter and 305 mm height and confined by CFRP tubes. Two different concrete mixes were examined, with average compressive strengths of 52.0 and 84.7 MPa. The effect of overlap configuration was examined by manufacturing the specimens with different properties at the overlap region including overlap length, continuity and distribution. Axial and lateral behavior was recorded to observe the axial stress–strain relationship and hoop strain behavior for concentric compression. Ultimate axial and lateral conditions are tabulated and stress–strain curves have been provided. Detailed plots of hoop strain development and lateral confinement pressure at ultimate are presented. The results indicate that FRP overlap length has no significant influence on strain enhancement ratio (ε cu /ε co), but an increase in overlap length leads to a slight increase in strength enhancement ratio (f′ cc /f′ co), with these observations equally applicable to both continuously and discontinuously wrapped specimens. The results also indicate that continuity of the FRP sheet in the overlap region has some influence on the effectiveness of FRP confinement. Furthermore, it was observed that the distribution of FRP overlap regions for discontinuously wrapped specimens can influence the axial compressive behavior of these specimens in certain overlap configurations. Finally, it is found that the distribution of lateral confining pressure around specimen perimeter becomes less uniform for specimens with higher concrete strengths and those manufactured with overlap regions that are not evenly distributed.

Similar content being viewed by others

Abbreviations

- D :

-

Diameter of concrete cylinder (mm)

- E f :

-

Modulus of elasticity of the fibers (MPa)

- Eff 1 :

-

Effectiveness of a given confinement arrangement in enhancing the ultimate strength (m−1)

- Eff 2 :

-

Effectiveness of a given confinement arrangement in enhancing the ultimate strain (m−1)

- f′ cc :

-

Peak axial compressive stress of FRP-confined concrete (MPa)

- \(\frac{{f'_{\text{cc}} }}{{f'_{\text{co}} }}\) :

-

Ultimate strength enhancement ratio

- f′ co :

-

Peak axial compressive stress of unconfined concrete (MPa)

- f′ cu :

-

Axial compressive stress of FRP-confined concrete at ε cu (MPa)

- f fu :

-

Ultimate tensile strength of fibers (MPa)

- f lu :

-

Ultimate lateral confinement pressure (MPa)

- f lu.i :

-

Ultimate lateral confinement pressure recorded at each strain gauge location (MPa)

- (f lu)avg :

-

Average ultimate lateral confining pressure (MPa)

- (f lu)C.V. :

-

Coefficient of variation for ultimate lateral confining pressures

- (f lu)S.D. :

-

Standard deviation of ultimate lateral confining pressures (MPa)

- k 1 :

-

Strength enhancement coefficient

- k 2 :

-

Strain enhancement coefficient

- k ε :

-

FRP strain reduction factor determined from strains outside overlap region

- k ε.overlap :

-

FRP strain reduction factor determined from strains within overlap region

- l FRP :

-

Total length of FRP sheet used in manufacturing the FRP jacket (m)

- n :

-

Number of layers of the fiber sheets outside the overlap region

- n i :

-

Number of layers of the fiber sheets at each strain gauge location

- n overlap :

-

Number of layers of the fiber sheets within the overlap region

- t f :

-

Total fiber thickness of FRP jacket (mm)

- ε co :

-

Axial compressive strain of unconfined concrete at f′ co

- ε cu :

-

Ultimate axial compressive strain of confined concrete

- \(\frac{{\varepsilon_{\text{cu}} }}{{\varepsilon_{\text{co}} }}\) :

-

Ultimate strain enhancement

- ε fu :

-

Ultimate tensile strain of fibers

- ε h.i :

-

The hoop strain recorded at each strain gauge location

- ε h,rup :

-

Hoop rupture strain of FRP shell recorded outside overlap region

- ε h,rup.overlap :

-

Hoop rupture strain of FRP shell recorded within overlap region(s)

References

Ozbakkaloglu T, Lim JC, Vincent T (2013) FRP-confined concrete in circular sections: review and assessment of the stress-strain models. Eng Struct 49:1068–1088

Ozbakkaloglu T, Lim JC (2013) Axial compressive behavior of FRP-confined concrete: experimental test database and a new design-oriented model. Compos Part B 55:607–634

Lim JC, Ozbakkaloglu T (2014) Confinement model for FRP-confined high-strength concrete. ASCE J Compos Constr 18(4):04013058

Wang LM, Wu YF (2008) Effect of corner radius on the performance of CFRP-confined square concrete columns: test. Eng Struct 30(2):493–505

Lam L, Teng JG (2004) Ultimate condition of FRP-confined concrete. ASCE J Compos Constr 8(6):539–548

Jiang T, Teng JG (2007) Analysis-oriented stress-strain models for FRP-confined concrete. Eng Struct 29(11):2968–2986

Berthet JF, Ferrier E, Hamelin H (2005) Compressive behavior of concrete externally confined by composite jackets. Part A: experimental study. Constr Build Mater 19(3):223–232

Karabinis AI, Rousakis TC (2002) Concrete confined by FRP material: a plasticity approach. Eng Struct 24(7):923–932

Ilki A, Kumbasar N (2003) Compressive behavior of carbon fiber composite jacketed concrete with circular and non-circular cross-sections. Earthq Eng 7(3):381–406

Zohrevand P, Mirmiran A (2012) Behavior of ultra high-performance concrete confined by fiber-reinforced polymers. Mater Civ Eng 23(12):1727–1734

Ozbakkaloglu T (2013) Behavior of square and rectangular ultra high-strength concrete-filled FRP tubes under axial compression. Compos Part B 54:97–111

Ozbakkaloglu T, Vincent T (2013) Axial compressive behavior of circular high-strength concrete-filled FRP tubes. ASCE J Compos Constr. doi:10.1061/(ASCE)CC.1943-5614.0000410

Vincent T, Ozbakkaloglu T (2013) Influence of concrete strength and confinement method on axial compressive behavior of FRP-confined high- and ultra high-strength concrete. Compos Part B 50:413–428

Vincent T, Ozbakkaloglu T (2013) Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete. Constr Build Mater 47:814–826

Lim JC, Ozbakkaloglu T (2014) Lateral strain-to-axial strain relationship of confined concrete. ASCE J Struct Eng. doi:10.1061/(ASCE)ST.1943-541X.0001094

Idris Y, Ozbakkaloglu T (2013) Seismic behavior of high-strength concrete-filled FRP tube columns. ASCE J Compos Constr 17(6):04013013

Lim JC, Ozbakkaloglu T (2014) Hoop strains in FRP-confined concrete columns: experimental observations. Mater Struct. doi:10.1617/s11527-014-0358-8

Ozbakkaloglu T, Louk Fanggi BA (2014) Axial compressive behavior of FRP-concrete-steel double-skin tubular columns made of normal- and high-strength concrete. ASCE J Compos Constr 18(1):04013027

Louk Fanggi BA, Ozbakkaloglu T (2013) Compressive behavior of aramid FRP-HSC-steel double-skin tubular columns. Constr Build Mater 48:554–565

Ozbakkaloglu T, Idris Y (2014) Seismic behavior of FRP-high-strength concrete-steel double skin tubular columns. ASCE J Struct Eng 140(6):04014019

Ozbakkaloglu T, Louk Fanggi BA (2013) FRP-HSC-steel composite columns: behavior under monotonic and cyclic axial compression. Mater Struct. doi:10.1617/s11527-013-0216-0

Smith ST, Kim SJ, Zhang H (2010) Behavior and effectiveness of FRP wrap in the confinement of large concrete cylinders. ASCE J Compos Constr 14:573–582

Lam L, Teng JG, Cheung CH, Xiao Y (2006) FRP-confined concrete under cyclic axial compression. Cem Concr Compos 28(10):948–958

Wu YF, Jiang JF (2013) Effective strain of FRP for confined circular concrete columns. Compos Struct 95:479–491

Wang Z, Wang D, Smith ST, Lu D (2012) CFRP-confined square RC columns. I: experimental investigation. ASCE J Compos Constr 16(2):150–160

Chen JF, Ai J, Stratford TJ (2010) Effect of geometric discontinuities on strains in FRP-wrapped columns. ASCE J Compos Constr 14(2):136–145

Lam L, Teng JG (2003) Design-oriented stress-strain model for FRP-confined concrete. Constr Build Mater 17(6&7):471–489

Xiao Y, Wu H (2003) Compressive behavior of concrete confined by various types of FRP composites jackets. Reinf Plast Compos 22(13):1187–1202

Jiang T, Teng JG (2006) Strengthening of short circular RC columns with FRP jackets: a design proposal. In: proceedings 3rd international conference on FRP composites in civil engineering. Miami

Matthys S, Toutanji H, Taerwe L (2006) Stress-strain behavior of large-scale circular columns confined with FRP composites. ASCE J Struct Eng 132(1):123–133

Mohamed H, Masmoudi R (2010) Axial Load Capacity of Concrete-Filled FRP Tube Columns: experimental versus Predictions. ASCE J Compos Constr 14(2):231–243

ASTM (2008) Standard test method for tensile properties of polymer matrix composites materials. ASTM D3039-M-08, West Conshohocken

Popovics S (1973) A numerical approach to the complete stress-strain curves for concrete. Cem Concr Res 3(5):583–599

Ozbakkaloglu T, Akin E (2012) Behavior of FRP-confined normal- and high-strength concrete under cyclic axial compression. ASCE J Compos Constr 16(4):451–463

Chen JF, Li SQ, Bisby L (2013) Factors affecting the ultimate condition of FRP-wrapped concrete columns. ASCE J Compos Constr 17(1):67–78

Bisby L, Take WA (2009) Strain localisations in FRP-confined concrete: new insights. Proc ICE-Struct Build 162(5):301–309

Acknowledgments

The authors would like to thank the Honour’s students Messrs. Gordon-Edwards, Ionko, Tang and Wang who performed the experimental procedures presented in this paper. The experimental work presented in this paper is part of an ongoing experimental program at The University of Adelaide on FRP-concrete composite columns.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vincent, T., Ozbakkaloglu, T. Influence of overlap configuration on compressive behavior of CFRP-confined normal- and high-strength concrete. Mater Struct 49, 1245–1268 (2016). https://doi.org/10.1617/s11527-015-0574-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0574-x