Abstract

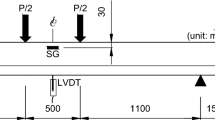

The use of energy dissipating materials both as reinforcement and as external devices for passive control of reinforced concrete structures is a widely accepted method in the construction industry. The present technologies have some limitations related to ageing, durability, corrosion and geometry restoration after strong events (for example, yielding in steel). An alternative reinforcement material such as shape memory alloy (SMA) could offer scope for having large recoverable deformations (self-centering ability), thus improving performance especially after a severe loading has occurred. In addition to enhancing the ductility of reinforced concrete, they can provide a wide range of performances, from full self-centering to high energy dissipation capabilities, as well as high resistance to large strain cycle fatigue and better durability. This paper reports on several experiments and analyses for evaluating the self-centering ability, ductility of beams and beam-column joint achieved by randomly distributed pseudoelastic SMA (PESMA) fibers. Three point loading experiments on prisms and specially designed prototype beam-column joint specimens with steel and PESMA fibers show that the ductility and self-centering ability of the composite with PESMA fibers is far superior to that of the steel fibers.

Similar content being viewed by others

References

Alam MS, Nehdi M, Youssef MA (2009) Seismic performance of concrete frame structures reinforced with superelastic shape memory alloys. Smart Struct Syst 5(5):565–585

Andrawes B, DesRoches R (2005) Unseating prevention for multiple frame bridges using superelastic devices. Smart Mater Struct 14:60–67

Aoude H, Cook DW, Mitchell D (2009) Behavior of columns constructed with fibers and self-consolidating concrete. ACI Struct J 106(3):349–357

ASTM C348–08 (2009) Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International, West Conshohocken, pp 1–6

Atimtay E, Kanit R (2006) Learning seismic design from the earthquake itself. Practice periodical on structural design and construction 11(3):149–160

Bentur A, Mindess S (1990) Fiber reinforced cementitious composites. Taylor & Francis Group, London, pp 1–587

Choi E, Nam TH, Cho BS (2005) A new concept of isolation bearings for highway steel bridges using shape memory alloys. Can J Civ Eng 32:957–967

Czaderski C, Hahnebach B, Motavalli M (2006) RC beam with variable stiffness and strength. Constr Build Mater 20(9):824–833

DesRoches R, Delemont M (2002) Seismic retrofit of simply supported bridges using shape memory alloys. Eng Struct 24:325–332

Dolce M, Cardone D, Palermo G (2007) Seismic Isolation of Bridges using Isolation Systems based on Flat Sliding Bearings. Bull Earthq Eng 5:491–509

Elbahy YI, Youssef MA, Nehdi M (2008) Stress block parameters for concrete flexural members reinforced with superelastic shape memory alloys. Mater Struct 42:1335–1351

Ghobarah A, Said A (2002) Shear strengthening of beam-column joints. Eng Struct 24:881–888

Hameed R, Duprat F, Turatsinze, A, Sellier A (2009) Mechanical properties of reinforced fibrous concrete beams under reverse cyclic loading. In: SBEIDCO, ENSET, Oran, Algeria, 12–14 October, pp 1–8

Janke L, Czaderski C, Motavalli M, Ruth J (2005) Applications of shape memory alloys in civil engineering structures—overview, limits and new ideas. Mater Struct 38:578–592

JCI-S-002 (2003) Method of test for load-displacement curve of fiber reinforced concrete by use of notched beam. JCI Standards for test of FRC, Tokyo, pp 1–6

Kuang SJ, Baczkowski JB (2009) Steel-fibre-reinforced concrete coupling beams subjected to monotonic loading. Mag Concr Res 61(1):35–41

Liu M, Li H, Song G, Ou J (2007) Investigation of vibration mitigation of stay cables incorporated with superelastic shape memory alloy dampers. Smart Mater Struct 16:2202–2213

Opara KN, Naaman EA (2000) Self-stressing fiber composites. ACI Struct J 97(2):335–345

Park R, Paulay T (1975) Reinforced concrete structure. Wiley, Hoboken

Parra-Montesinos JG (2005) High-performance fiber-reinforced cement composites: an alternative for seismic design of structures. ACI Struct J 102(5):668–675

Rao GA, Rao AS (2009) Toughness indices of steel fiber reinforced concrete under mode II loading. Mater Struct 42:1173–1184

Shaheen E, Shrive GN (2007) Cyclic loading and fracture mechanics of Ductal concrete. Int J Fract 148:251–260

Shajil N, Das D, Chandrasekaran L (2009) Effects of cycling on the pseudoelastic properties of CuAlMnNi & NiTi based pseudoelastic alloys. Int J Struct Changes Solids 1:171–185

Shajil N, Srinivasan SM, Santhanam M (2013) Self-centering of shape memory alloy fiber reinforced cement mortar members subjected to strong cyclic loading. Mater Struct 46:651–661

Song G, Ma N, Li NH (2006) Applications of shape memory alloys in civil structures. Eng Struct 28:1266–1274

Ward JR, Li VC (1991) Dependence of flexural behaviour of fibre reinforced mortar on material fracture resistance and beam size. Constr Build Mater 5(3):151–161

Wilde K, Gardoni P, Fujimo Y (2000) Base isolation system with shape memory alloy device for elevated bridges. Eng Struct 22:222–229

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shajil, N., Srinivasan, S.M. & Santhanam, M. An experimental study on self-centering and ductility of pseudo-elastic shape memory alloy (PESMA) fiber reinforced beam and beam-column joint specimens. Mater Struct 49, 783–793 (2016). https://doi.org/10.1617/s11527-015-0538-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0538-1