Abstract

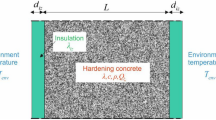

Thermal analysis of mass concrete is often carried out through finite element (FE) analysis. The heat release rate in a material point can be determined from a small-scale isothermal calorimeter. Nonetheless, isothermal calorimeter is generally an expensive device and lacks practicality. In that light, this paper proposes a low-cost semi-adiabatic calorimeter setup complemented with a FE analysis. Such a combination provides evolution of hydration heat under isothermal temperature and enables upscaling to the temperature evolution in mass concrete structures. The upscaling process is demonstrated on three mass concrete blocks. Initially, semi-adiabatic measurements start on 14 dm3 concrete cube to identify the heat release rate. Next, the calibrated hydration model is upscaled and validated on a 1.0 m3 concrete cube and two mass concrete foundation blocks with 511 and 1,050 m3. The validation proves successfully the upscaling approach; also, the same temperature-dependent hydration kinetics performs well from small to large scales.

Similar content being viewed by others

References

ACI 207.1R-05: Guide to Mass Concrete (2005). Farmington Hills

Bamforth P (2003) Concreting large-volume (mass) pours. In Newman J, Choo BS (eds) Advanced concrete technology. Butterworth-Heinemann, Oxford, pp 1–47

Bentz D (2000) A three-dimensional cement hydration and microstructure development modeling package. Tech. Rep. Version 3.0. NIST Building and Fire Research Laboratory, Gaithersburg

Brazilian Association of Technical Standards: NBR 5736: Pozzolanic Portland Cement—Specification (1991). Rio de Janeiro, Brazil

Brazilian Association of Technical Standards: NBR 7219: aggregates for concrete—determination of pulverulent materials content—test method (2000). Rio de Janeiro, Brazil

Brazilian Association of Technical Standards: NBR NM248: aggregates—sieve analysis of fine and coarse aggregates (2003). Rio de Janeiro, Brazil

Brazilian Association of Technical Standards: NBR NM53: Coarse aggregate—determination of the bulk specific gravity, apparent specific gravity, and water absorption (2003). Rio de Janeiro, Brazil

Brazilian Association of Technical Standards: NBR 7212: aggregates for concrete—specification (2005). Rio de Janeiro, Brazil

Cervera M, Oliver J, Prato T (1999) Thermo-chemo–mechanical model for concrete. I: hydration and aging. J Eng Mech ASCE 125(9):1018–1027. doi:10.1061/(ASCE)0733-9399(1999)125:9(1018)

Choktaweekarn P, Tangtermsirikul S (2010) Effect of aggregate type, casting, thickness and curing condition on restrained strain of mass concrete. Songklanakarin J Sci Technol 32(4):391–402

Coussy O (1995) Mechanics of porous media. Wiley, New York

Faria R, Azenha M, Figueiras JA (2006) Modelling of concrete at early ages: application to an externally restrained slab. Cem Concr Compos 28(6):572–585. doi:10.1016/j.cemconcomp.2006.02.012

Gawin D, Pesavento F, Schrefler BA (2006) Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. part i: hydration and hygro-thermal phenomena. Int J Numer Methods Eng 67(3):299–331. doi:10.1002/nme.1615

Gawin D, Pesavento F, Schrefler BA (2006) Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. part ii: shrinkage and creep of concrete. Int J Numer Methods Eng 67(3):332–363. doi:10.1002/nme.1636

Guo L, Guo L, Zhong L, Zhu Y (2011) Thermal conductivity and heat transfer coefficient of concrete. J Wuhan Univ Technol Mater Sci Ed 26(4):791–796. doi:10.1007/s11595-011-0312-3

Hellmich C, Mang HA, Ulm FJ (2001) Hybrid method for quantification of stress states in shotcrete tunnel shells: combination of 3D in situ displacement measurements and thermochemoplastic material law. Comput Struct 79(22–25):2103–2115. doi:10.1016/S0045-7949(01)00057-8

Hughes TJR (2000) The Finite element method: linear static and dynamic finite element analysis. Dover Publications, Mineola

Jendele L, Šmilauer V, Červenka J (2013) Multiscale hydro-thermo-mechanical model for early-age and mature concrete structures. Adv Eng Softw. doi:10.1016/j.advengsoft.2013.05.002

Kim KH, Jeon SE, Kim JK, Yang S (2003) An experimental study on thermal conductivity of concrete. Cem Concr Res 33(3):363–371. doi:10.1016/S0008-8846(02)00965-1

Kosmatka S, Kerkhoff B, Panarese W (2003) Design and control of concrete mixtures, 14th edn. Portland Cement Association, Skokie

Mehta P, Monteiro P (2005) Concrete: microstructure, properties, and materials. McGraw-Hill, New York

Nawy E (2008) Concrete Construction engineering handbook, 2nd edn. CRC Press, Boca Raton

Neville AM (1997) Properties of concrete, 4th edn. Wiley, London

NRMCA (2007) Concrete in practice. National Ready Mixed Concrete Association, Silver Spring

Patzák B, Rypl D (2012) Object-oriented, parallel finite element framework with dynamic load balancing. Adv Eng Softw 47(1):35–50. doi:10.1016/j.advengsoft.2011.12.008

Ulm FJ, Coussy O (1998) Couplings in early-age concrete: from material modeling to structural design. Int J Solids Struct 35(31–32):4295–4311. doi:10.1016/S0020-7683(97)00317-X

Šmilauer V (2013) Multiscale hierarchical modeling of hydrating concrete. Saxe-Coburg Publications, Stirling

Štemberk P, Rainová A (2011) Simulation of hydration and cracking propagation with temperature effect based on fuzzy logic theory. Mechanika 17(4):358–362. doi:10.5755/j01.mech.17.4.561

Weiss W, Yang W, Shah S (1999) Factors influencing durability and early-age cracking in high strength concrete structures. In: High performance concrete: research to practice, SP 189-22. American Concrete Institute, Farmington Hills, pp 387–409

Acknowledgments

We gratefully acknowledge the support of the project "Support for improving teams in research and development and the development of intersectoral mobility at Czech Technical University in Prague" OP VK CZ.1.07/2.3.00/30.0034, which allowed for funding of Dr. da Silva’s postdoctoral research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Silva, W.R.L., Šmilauer, V. & Štemberk, P. Upscaling semi-adiabatic measurements for simulating temperature evolution of mass concrete structures. Mater Struct 48, 1031–1041 (2015). https://doi.org/10.1617/s11527-013-0213-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-013-0213-3