Abstract

The recommendations presented in this publication are inspired by the State of the Art Report edited by the RILEM Technical Committee TC 193 RLS Bonded cement-based material overlays for the repair, the lining or the strengthening of slabs and pavements. The objective is to lay out all the practical aspects to be considered in the design of concrete overlays: bonded concrete overlay process, assessment of the existing structure, surface preparation, overlay materials, design methods, construction procedure and quality control/assurance system, and maintenance.

Résumé

Ces recommandations s’inspirent de l’état de l’art issu des travaux du Comité Technique RILEM TC 193 RLS Réparation, re-surfaçage ou renforcement des dallages industriels ou des chaussées par un rechargement adhérent à base cimentaire. Elles visent à donner aux chercheurs, ingénieurs et auteurs de projets les données fondamentales à prendre en considération lors de l’élaboration d’un projet de resurfaçage : processus de décision, évaluation de la structure existante, préparation de la surface, matériaux de re-surfaçage, conception, construction, contrôle qualité et entretien.

Similar content being viewed by others

References

Bissonnette B, Courard L, Fowler D, Granju JL (2011) Bonded cement-based material overlays for the repair, the lining or the strengthening of slabs and pavements. In: RILEM STAR Report, vol 3, 193-RLS RILEM TC. Springer, Dordrecht

Vaysburd AM, Emmons PH (2000) How to make today’s repairs durable for tomorrow—corrosion protection in concrete repair. Constr Build Mater 14(4):189–197

EN 1504-10 (2004) Products and systems for the protection and repair of concrete structures—definitions, requirements, quality control and evaluation of conformity. CEN, Brussels

ACI 364.1-R07 (2007) Guide for evaluation of concrete structures before rehabilitation. Committee 364 Rehabilitation, American Concrete Institute, Detroit

Carino NJ (2003) Non destructive test methods to evaluate concrete structures. In: Sixth CANMET/ACI international conference on the durability of concrete, special seminar, Thessaloniki

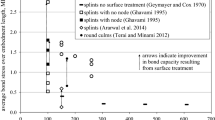

Silfwerbrand J, Beushausen H (2005) Bonded concrete overlays—bond strength issues. In: Proceedings, international conference on concrete repair, rehabilitation and retrofitting, Cape Town, 21–23 Nov 2005, pp 19–21 (Extended version on conference CD)

Bissonnette B, Courard L, Vaysburd A, Bélair N (2006) Concrete removal techniques: influence on residual cracking and bond strength. Concr Int 28(12):49–55

Emmons PH, Vaysburd AM (1993) Compatibility considerations for durable concrete repairs. Transp Res Rec 1382:13–19

Emberson NK, Mays GC (1990) Significance of property mismatch in the patch repair of structural concrete—part 1: properties of repair systems. Mag Concr Res 42(152):147–160

Pigeon M, Saucier F (1992) Durability of repaired concrete structures. In: Malhotra VM (ed) Advances in concrete technology, Compte-rendus de conférence, Athènes, pp 741–773

Bissonnette B (1996) Le fluage en traction: un aspect important de la problématique des réparations minces en béton. Thèse de doctorat, Université Laval, Québec

Pigeon M, Bissonnette B (1999) Tensile creep and cracking potential of bonded concrete repairs. Concr Int 21(11):31–35

Bissonnette B, Boily D, Bastien J, Fafard M (2001) Tensile creep of concrete repair materials: recent experimental findings towards optimization. In: RILEM 6th international conference on creep, shrinkage & durability mechanics of concrete and other quasi-brittle materials, Boston, 20–22 août, pp 599–604

ACPA (1990) Guidelines for bonded concrete overlays. Technical Bulletin TB-007P, American Concrete Pavement Association, Arlington Heights

ACI 325.13-R06 (2006) Concrete overlays for pavement rehabilitation. Committee 325 Pavements, American Concrete Institute, Detroit

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bissonnette, B., Courard, L., Beushausen, H. et al. Recommendations for the repair, the lining or the strengthening of concrete slabs or pavements with bonded cement-based material overlays. Mater Struct 46, 481–494 (2013). https://doi.org/10.1617/s11527-012-9929-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-012-9929-8