Abstract

This review paper aims at giving an overview of the different applications of thermodynamic equilibrium calculations in cementitious systems. They can help us to understand on a chemical level the consequences of different factors such as cement composition, hydration, leaching, or temperature on the composition and the properties of a hydrated cementitious system. Equilibrium calculations have been used successfully to compute the stable phase assemblages based on the solution composition as well as to model the stable phase assemblage in completely hydrated cements and thus to asses the influence of the chemical composition on the hydrate assemblage. Thermodynamic calculations can also, in combination with a dissolution model, be used to follow the changes during hydration or, in combination with transport models, to calculate the interactions of cementitious systems with the environment. In all these quite different applications, thermodynamic equilibrium calculations have been a valuable addition to experimental studies deepening our understanding of the processes that govern cementitious systems and interpreting experimental observations. It should be carried in mind that precipitation and dissolution processes can be slow so that thermodynamic equilibrium may not be reached; an approach that couples thermodynamics and kinetics would be preferable. However, as many of the kinetic data are not (yet) available, it is important to verify the results of thermodynamic calculations with appropriate experiments. Thermodynamic equilibrium calculations in its different forms have been applied mainly to Portland cement systems. The approach, however, is equally valid for blended systems or for cementitious systems based on supplementary cementitious materials and is expected to further the development of new cementitious materials and blends.

Similar content being viewed by others

Notes

An isoelectric reaction exhibits equal charges on both sides such as \( {\text{Ca}}^{2 + } + {\text{H}}_{2} {\text{O}} \leftrightarrow {\text{CaOH}}^{ + } + {\text{OH}}^{ + } \), while an isocoulombic reaction is a reaction with identically charged species on either side (e.g., \( {\text{Cl}}^{ - } + {\text{H}}_{ 2} {\text{O}} \leftrightarrow {\text{HCl}} + {\text{OH}}^{ - } \)).

References

Parkhurst DJ, Appelo CAJ (1999) User’s Guide to PHREEQC (version 2): a computer program for speciation, batch reaction, one dimensional transport, and inverse geochemical calculations, in Water-Resources Investigation Report, Denver, Colorado

Westall JC, Zachary JL, Morel FMM (1976) MINEQL. Department of Civil Engineering, MIT, Cambridge, MA

Wolery TJ (1992) EQ3/6, A software package for geochemical modeling of aqueous systems: package overview and installation guide (version 7). Lawrence Livermore National Laboratory, Livermore, CA

van der Lee J, De Windt L (2002) CHESS tutorial and cookbook. Updated for version 3.0. Ecole Nationale Supérieure des Mines de Paris, Paris

Kulik D, Berner U, Curti E (2004) Modelling geochemical equilibrium partitioning with the GEMS-PSI Code. In: Smith B, Gschwend B (eds) PSI Scientific Report 2003/vol IV. Nuclear energy and safety. Paul Scherrer Institute, Villigen, Switzerland

Kulik D (2007) GEMS-PSI 2.2, available at http://gems.web.psi.ch/. PSI, Villigen, Switzerland

Rothstein D, Thomas JJ, Christensen BJ, Jennings HM (2002) Solubility behavior of Ca-, S-, Al-, and Si-bearing solid phases in Portland cement pore solutions as a function of hydration time. Cem Concr Res 32(10):1663–1671

Stark J, Möser B, Bellmann F (2007) Quantitative characterization of cement hydration. In: Setzer M (eds) Proceedings of the 5th International Essen Workshop, Transport in Concrete: nano- to macrostructure. Essen, Germany, Aedification Publishers, Freiburg June 11–13, pp 161–179

Lothenbach B, Le Saout G, Gallucci E, Scrivener K (2008) Influence of limestone on the hydration of Portland cements. Cem Concr Res 38(6):848–860

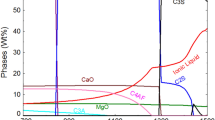

Lothenbach B, Matschei T, Möschner G, Glasser FP (2008) Thermodynamic modelling of the effect of temperature on the hydration and porosity of Portland cement. Cem Concr Res 38(1):1–18

Atkins M, Glasser FP, Moron IP, Jack JJ (1993) Thermodynamic modelling of blended cements at elevated temperature (50–90°C). DOE report DoE/HIMP/RR/94.011

Juel I, Herfort D, Gollop R, Konnerup-Madsen J, Jakobsen HJ, Skibsted J (2003) A thermodynamic model for predicting the stability of thaumasite. Cem Conc Comp 25:867–872

Matschei T, Lothenbach B, Glasser FP (2007) The role of calcium carbonate in cement hydration. Cem Concr Res 37(4):551–558

Nielsen EP, Herfort D, Geiker MR (2005) Phase equilibria of hydrated Portland cement. Cem Concr Res 35:109–115

Reardon EJ (1992) Problems and approaches to the prediction of the chemical composition in cement/water systems. Waste Manag 12:221–239

Lee JH, Roy DM, Mann B, Stahl D (1995) Integrated approach to modeling long-term durability of concrete engineered barriers in LLRW disposal facility. Mat Res Soc Symp Proc 353:881–889

Lothenbach B, Winnefeld F (2006) Thermodynamic modelling of the hydration of Portland cement. Cem Concr Res 36(2):209–226

Guillon E, Chen J, Chanvillard G (2008) Physical & chemical modeling of the hydration kinetics of OPC paste using a semi-analytical approach. In: Schlangen E, De Schutter G (eds) Proceedings of the International RILEM symposium on Concrete Modelling: CONMOD’08, 26–28 May 2008. RILEM Publications, Delft, The Netherlands, pp 165–172

Samson E, Marchand J, Beaudoin JJ (2000) Modeling the influence of chemical reactions on the mechanisms of ionic transport in porous materials: an overview. Cem Concr Res 30:1895–1902

Marchand J, Samson E, Maltais Y, Beaudoin JJ (2002) Theoretical analysis of the effect of weak sodium sulfate solutions on the durability of concrete. Cem Conc Comp 24(3–4):317–329

Maltais Y, Samson E, Marchand J (2004) Predicting the durability of Portland cement systems in aggressive environments-laboratory validation. Cem Concr Res 34(9):1579–1589

van der Lee J, De Windt L, Lagneau V (2008) Application of reactive transport models in cement-based porous media. In: Schlangen E, De Schutter G (eds) Proceedings of the International RILEM symposium on Concrete Modelling: CONMOD’08, 26–28 May 2008. RILEM Publications, Delft, The Netherlands, pp 463–470

Barbarulo R (2008) Modeling chemical degradations of cement pastes in contact with aggressive solutions: leaching and carbonation. In: Schlangen E, De Schutter G (eds) Proceedings of the International RILEM symposium on Concrete Modelling: CONMOD’08, 26–28 May 2008. RILEM Publications, Delft, The Netherlands, pp 213–223

Neuville N, Lecolier E, Aouad G, Damidot D (2008) Characterisation and modelling of physico-chemical degradation of cement-based materials used in oil wells. In: Schlangen E, De Schutter G (eds) Proc International RILEM symposium on Concrete Modelling: CONMOD’08, 26–28 May 2008. RILEM Publications, Delft, The Netherlands, pp 191–198

Berner UR (1987) Modelling porewater chemistry in hydrated Portland cement. Mat Res Soc Symp Proc 84:319–330

Glasser FP (1988) Modelling approach to the prediction of equilibrium phase distribution in slag-cement belnds and their solubility properties. Mat Res Soc Symp Proc 112:3–12

Reardon EJ (1990) An ion interaction model for the determination of chemical equilibria in cement/water systems. Cem Concr Res 20:175–192

Berner U (1990) A thermodynamic description of the evolution of pore water chemistry and uranium speciation during degradation of cement. PSI, Villigen, Switzerland

Atkins M, Bennett DG, Dawes AC, Glasser FP, Kindness A, Read D (1992) A thermodynamic model for blended cements. Cem Concr Res 22(2–3):497–502

Atkins M, Glasser FP, Kindness A (1992) Cement hydrate phases: solubility at 25°C. Cem Concr Res 22:241–246

Bennett DG, Read D, Atkins M, Glasser FP (1992) A thermodynamic model for blended cements. II: Cement hydrate phases; thermodynamic values and modelling studies. J Nucl Mater 190:315–325

Damidot D, Glasser FP (1992) Thermodynamic investigation of the CaO–Al2O3–CaSO4–H2O system at 50°C and 85°C. Cem Concr Res 22:1179–1192

Damidot D, Stronach S, Kindness A, Atkins M, Glasser FP (1994) Thermodynamic investigation of the CaO–Al2O3–CaCO3–H2O closed system at 25° C and the influence of Na2O. Cem Concr Res 24(3):563–572

Neall FB (1994) Modelling of the near-field chemistry of the SMA repository at the Wellenberg Site. PSI, Villigen, Switzerland

Damidot D, Glasser FP (1995) Investigation of the CaO–Al2O3–SiO2–H2O system at 25°C by thermodynamic calculations. Cem Concr Res 25(1):22–28

Jacques D (2008) Benchmarking of the cement model and detrimental chemical reactions including temperature dependent parameters, SCK–CEN, NIRAS-MP5-03-XX

Appelo CAJ, Postma D (1996) Geochemistry, groundwater and pollution. A.A. Balkema, Rotterdam

Anderson GM, Crerar DA (1993) Thermodynamics in geochemistry: the equilibrium model. Oxford University Press, Oxford

Stumm W, Morgan JJ (1996) Aquatic chemistry: chemical equilibria and rates in natural waters, 3rd edn. Environmental Science and Technology. Wiley, New York

Kulik D (2002) Gibbs energy minimization approach to modeling sorption equilibria at the mineral interface: thermodynamic relations for multi-site surface complexation. Am J Sci 302:227–279

Nordstrom DK, Munoz JL (1988) Geochemical thermodynamics. Blackwell, Boston

Perkins RB, Palmer CD (1999) Solubility of ettringite (Ca6[Al(OH)6]2(SO4)3·26H2O) at 5–75°C. Geochim Cosmochim Ac 63(13/14):1969–1980

Matschei T, Lothenbach B, Glasser FP (2007) Thermodynamic properties of Portland cement hydrates in the system CaO–Al2O3–SiO2–CaSO4–CaCO3–H2O. Cem Concr Res 37(10):1379–1410

Parkhurst DJ (1990) Ion-association models and mean activity coefficients of various salts. In: Melchior DC, Bassett RL (eds) Chemical modeling of aqueous systems II. ACS Symposium series 416. American Chemical Society, Washington, DC, pp 30–43

Helgeson HC, Kirkham DH, Flowers GC (1981) Theoretical prediction of the thermodynamic behaviour of aqueous electrolyte at high pressures and temperatures. IV. Calculation of activity coefficients, osmotic coefficients, and apparent molal and standard and relative molal properties to 600°C and 5 kb. Am J Sci 281(10):1249–1516

Grenthe I, Puidomenech I (1997) Modelling in aquatic chemistry. OECD Nuclear Chemistry, Paris, France

Pitzer KS (1991) Ion interaction approach: theory and data correlation. In: Pitzer KS (ed) Activity coefficients in electrolyte solutions. CRC Press, Boca Raton, pp 75–153

Viallis H, Faucon P, Petit JC, Nonat A (1999) Interactions between salts (NaCl, CsCl) and calcium-silicate hydrates (C-S-H). J Phys Chem B 103(25):5212–5219

Viallis-Terrisse H, Nonat A, Petit JC (2001) Zeta-potential study of calcium silicate hydrates interacting with alkaline cations. J Colloid Interface Sci 253(1):140–149

Barbarulo R, Peycelon H, Prene S (2003) Experimental study and modelling of sulfate sorption on calcium silicate hydrate. Ann Chim Sci Mater 1(Suppl):S5–S10

Wieland E, Tits J, Kunz D, Dähn R (2008) Strontium uptake by cementitious materials. Environ Sci Technol 42(2):403–409

Johannesson B, Yamada K, Nilsson L-O, Hosokawa Y (2007) Multi-species ionic diffusion in concrete with account to interaction between ions in the pore solution and the cement hydrates. Mater Struct 40:651–665

Hosokawa Y, Yamada K, Johannesson B, Nilsson L-O (2008) A development of a multi-species mass transport model considering thermodynamic phase equilibrium. In: Schlangen E, De Schutter G (eds) Proceedings of the International RILEM symposium on Concrete Modelling: CONMOD’08. PILEM Publications SARL, PRO 58, Delft, The Netherlands, pp 543–550

Labbez C, Nonat A, Pochard I, Jönsson B (2007) Experimental and theoretical evidence of overcharging calcium silicate hydrate. J Colloid Interface Sci 309(2):303–307

Kulik DA, Kersten M (2001) Aqueous solubility diagrams for cementitious waste stabilization systems: II, End-member stoichiometries of ideal calcium silicates hydrate solid solutions. J Am Ceram Soc 84(12):3017–3026

Macphee DE, Barnett SJ (2004) Solution properties of solids in the ettringite-thaumasite solid solution series. Cem Concr Res 34:1591–1598

Lothenbach B (2008) Thermodynamic modelling of the effect of temperature on the hydration of Portland cement. In: Schlangen E, De Schutter G (eds) Proceedings of the International RILEM symposium on Concrete Modelling: CONMOD’08, 26–28 May 2008. RILEM Publications, Delft, The Netherlands, pp 393–400

Möschner G, Lothenbach B, Ulrich A, Figi R, Kretschmar R (2009) Solid solution between Al-ettringite and Fe-ettringite (Ca6[Al1-xFex(OH)6]2(SO4)3·26H2O). Cem Concr Res 39:482–489

Bruno J, Bosbach D, Kulik D, Navrotsky A (2007) Chemical thermodynamics, vol 10. Chemical thermodynamics of solid solutions of interest in nuclear waste management. North-Holland/Elsevier, Amsterdam, The Netherlands

Curti E (1999) Coprecipitation of radionuclides with calcite: estimation of partition coefficients based on a review of laboratory investigations and geochemical data. Appl Geochem 14(4):433–445

Helgeson HC, Delany JM, Nesbitt HW, Bird DK (1978) Summary and critique of the thermodynamic properties of rock-forming minerals. Am J Sci 278-A:1–229

Babushkin VI, Matveyev GM, Mchedlov-Petrossyan OP (1985) Thermodynamics of silicates. Springer, Berlin

Johnson JW, Oelkers EH, Helgeson HC (1992) SUPCRT92: a software package for calculating the standard molal thermodynamic properties of minerals, gases, aqueous species, and reactions from 1 to 5000 bar and 0 to 1000°C. Comput Geosci 18(7):899–947

Robie RA, Hemingway BS (1995) Thermodynamic properties of minerals and related substances at 298.15 K and 1 bar (105 Pascals) pressure and at higher temperatures. US Geol Surv Bull 2131:461.

Shock EL, Sassani DC, Willis M, Sverjensky DA (1997) Inorganic species in geologic fluids: correlations among standard molal thermodynamic properties of aqueous ions and hydroxide complexes. Geochim Cosmochim Acta 61(5):907–950

Sverjensky DA, Shock EL, Helgeson HC (1997) Prediction of the thermodynamic properties of aqueous metal complexes to 1000°C and 5 kb. Geochim Cosmochim Acta 61(7):1359–1412

Hummel W, Berner U, Curti E, Pearson FJ, Thoenen T (2002) Nagra/PSI chemical thermodynamic data base 01/01. Universal Publishers/uPUBLISH.com, USA (also published as Nagra Technical Report NTB 02-16, Wettingen, Switzerland)

Babushkin VI, Matveev OP, Mčedlov-Petrosjan OP (1965) Thermodinamika silikatov. Strojisdat, Moskau

Nikushchenko VM, Khotimchenko VS, Rumyantsev PF, Kalinin AI (1973) Determination of the standard free energies of formation of calcium hydroxyaluminates. Cem Concr Res 3:625–632

Barret P, Bertrandie D, Beau D (1983) Calcium hydrocarboaluminate, carbonate, alumina gel and hydrated aluminates solubility diagram calculated in equilibrium with CO2g and with Na +aq ions. Cem Concr Res 13:789–800

Bourbon X (2003) Chemical conceptual model for cement based materials, mineral phases and thermodynamic data, ANDRA Technical Report C.NT.ASCM.03.026.A

Schmidt T, Lothenbach B, Romer M, Scrivener KL, Rentsch D, Figi R (2008) A thermodynamic and experimental study of the conditions of thaumasite formation. Cem Concr Res 38(3):337–349

Möschner G, Lothenbach B, Rose J, Ulrich A, Figi R, Kretschmar R (2008) Solubility of Fe-ettringite (Ca6[Fe(OH)6]2(SO4)3·26H2O). Geochim Cosmochim Acta 72(1):1–18

Stade H (1989) On the reaction of C-S-H(di, poly) with alkali hydroxides. Cem Concr Res 19:802–810

Hong S-Y, Glasser FP (1999) Alkali binding in cement pastes. Part I. The C-S-H phase. Cem Concr Res 29:1893–1903

Hong S-Y, Glasser FP (2002) Alkali sorption by C-S-H and C-A-S-H gels. Part II. Role of alumina. Cem Concr Res 32(7):1101–1111

Taylor HFW (1987) A method for predicting alkali ion concentrations in cement pore solutions. Adv Cem Res 1(1):5–17

Brouwers HJH, van Eijk RJ (2003) Alkali concentrations of pore solution in hydrating OPC. Cem Concr Res 33:191–196

Kulik D, Tits J, Wieland E (2007) Aqueous-solid solution model of strontium uptake in C-S-H phases’. Geochim Cosmochim Acta 71(12, Suppl 1):A530

Faucon P, Delagrave A, Petit JC, Richet C, Marchand J, Zanni H (1999) Aluminium incorporation in calcium silicate hydrates (C-S-H) depending on their Ca/Si ratio. J Phys Chem B 103:7796–7802

Matschei T, Skapa R, Lothenbach B, Glasser FP (2007) The distribution of sulfate in hydrated Portland cement paste, Proceedings of the 12th ICCC, Montreal, Canada, 9–12 July 2007, pp W1-05.2

Schwiete HE, Iwai T (1964) The behaviour of the ferritic phase in cement during hydration. Zement-Kalk-Gips 17:379–386

Gollop RS, Taylor HFW (1994) Microstructural and microanalytical studies of sulfate attack. II. Sulfate-resisting Portland cement: ferrite composition and hydration chemistry. Cem Concr Res 24(7):1347–1358

Paul M, Glasser FP (2000) Impact of prolonged warm (85 degrees C) moist cure on Portland cement paste. Cem Concr Res 30(12):1869–1877

Collier NC, Milestone NB, Hill J, Godfrey IH (2006) The disposal of radioactive ferric floc. Waste Manage 26(7):769–775

Taylor HFW (1997) Cement chemistry. Thomas Telford Publishing, London

Johnson CA, Glasser FP (2003) Hydrotalcite-like minerals (M2Al(OH)6(CO3)0.5·xH2O, where M = Mg, Zn, Co, Ni) in the environment: synthesis, characterisation and thermodynamic stability. Clay Clay Miner 51:1–8

Allada RK, Navrotsky A, Boerio-Goates J (2005) Thermochemistry of hydrotalcite-like phases in the MgO–-Al2O3–CO2–H2O system: a determination of enthalpy, entropy, and free energy. Am Miner 90(2–3):329–335

Garrault S, Finot E, Lesniewska E, Nonat A (2005) Study of C-S-H growth on C3S surface during its early hydration. Mater Struct 38:435–442

Garrault S, Nonat A (2001) Hydrated layer formation on tricalcium and dicalcium silicate surfaces: experimental study and numerical simulations. Langmuir 17:8131–8138

Bullard JW (2008) A determination of hydration mechanisms for tricalcium silicate using a kinetic cellular automaton model. J Am Ceram Soc 91(7):2088–2097

Damidot D, Bellmann F, Möser B, Sovoidnich T (2007) Investigation of the early dissolution behavior of C3S. In: Proceedings of the 12th ICCC, Montreal, Canada, 9–12 July 2007, pp W1-06.5

Minard H, Garrault S, Regnaud L, Nonat A (2007) Mechanisms and parameters controlling the tricalcium aluminate reactivity in the presence of gypsum. Cem Concr Res 37:1418–1426

Juilland P, Gallucci E, Flatt RJ, Scrivener K (2009) Mechanisms of hydration of cementitious materials at early age. In: Proceedings of the 17th Internationale Baustofftagung (ibausil), 23–26 September 2009, vol 1. Weimar, Germany, pp 1-0201–1-0206

Bishnoi S, Scrivener KL (2009) Studying nucleation and growth kinetics of alite hydration using [mu]ic. Cem Concr Res 39(10):849–860

Parrot LJ (1986) Modelling the development of microstructure. In: Henniker NH (ed) Proceedings of the Research on the manufacture and use of cements. Engineering Foundation, New York, pp 43–73

Wells LS, Clarke WF, McMurdie HF (1943) Study of the system CaO–Al2O3–H2O at temperature of 21 and 90°C. J Res Nat Bur Stand 30:367–409

Peppler RB, Wells LS (1954) The system of lime, alumina, and water from 50 to 250°C. J Res Nat Bur Stand 52(2):75–92

Jappy TG, Glasser FP (1991) Synthesis and stability of silica-substituted hydrogarnet Ca3Al2Si3-xO12–4x(OH)4x. Adv Cem Res 4:1–8

Lothenbach B, Wieland E (2006) A thermodynamic approach to the hydration of sulphate-resisting Portland cement. Waste Manag 26(7):706–719

Schott J, Pokrovsky OS, Oelkers EH (2009) The link between mineral dissolution/precipitation kinetics and solution chemistry. In: Oelkers EH, Schott J (eds) Reviews in mineralogy and geochemistry, vol 70. Thermodynamics and kinetics of water-rock interaction. Mineralogical Society of America Geochemical Society, Chantilly, VA

Brantley SL (2008) Kinetics of mineral dissolution. In: Brantley SL, Kubicki JD, White AF (eds) Kinetics of rock-water interaction. Springer, New York

Chou L, Garrels RM, Wollast R (1989) Comparative study of the kinetics and mechanisms of dissolution of carbonate minerals. Chem Geol 78:269–282

Inskeep WP, Bloom PR (1985) An evaluation of rate equations for calcite precipitation kinetics at pCO2 less than 0.01 atm and pH greater than 8. Geochim Cosmochim Ac 49:2165–2180

Kontrec J, Kralj D, Brecevic L (2002) Transformation of anhydrous calcium sulphate into calcium sulphate dihydrate in aqueous solutions. J Cryst Growth 240:203–211

Zhang J, Nancollas GH (1992) Influence of calcium/sulfate molar ratio on the growth rate of calcium sulfate dihydrate at constant supersaturation. J Cryst Growth 118:287–294

Barret P, Bertrandie D (1980) Courbe d’instabilité minimale dans une solution métastable de CA. 7th ICCC 3-V, pp 134–139

Fujii K, Kondo W, Ueno H (1986) Kinetics of hydration of monocalcium aluminate. J Am Ceram Soc 69(4):361–364

Bertrandie D, Barret P (1986) Hydration elementary interfacial steps of calcium aluminates as cement compounds. In: Proceedings of the 8th International Congress on the Chemistry of Cement, vol 3, Rio de Janeiro, pp 79–85

Damidot D (2007) Calculation of critically supersaturated domains with respect to ettringite in the CaO–Al2O3–CaSO4–H2O system at 20°C. In: Proceedings of the 12th ICCC, Montreal, Canada, 9–12 July 2007, pp W1-05.5

Gartner EM, Tang FJ, Weiss SJ (1985) Saturation factors for calcium hydroxide and calcium sulfates in fresh Portland cement pastes. J Am Ceram Soc 68(12):667–673

Michaux M, Fletcher P, Vidick B (1989) Evolution at early hydration times of the chemical composition of liquid phase of oil-well cement pastes with and without additives. Part I. Additive free cement pastes. Cem Concr Res 19:443–456

Goldschmidt A (1982) About the hydration theory and the composition of the liquid phase of Portland cement. Cem Concr Res 12:743–746

Locher FW, Richartz W, Sprung S (1976) Erstarren von zement I: reaktion und gefügeentwicklung. Zement-Kalk-Gips 29(10):435–442

Vernet C, Démoulian E, Gourdin P, Hawthorn F (1980) Hydration kinetics of Portland cement. 7th ICCC II 219–224

Vernet C, Démoulian E, Gourdin P, Hawthorn F (1980) Kinetics of slag cements hydration. 7th ICCC III, pp 128–133

Locher FW, Richartz W, Sprung S, Rechenberg W (1983) Erstarren von zement IV: einfluss der lösungszusammensetzung. Zement-Kalk-Gips 36(4):224–231

Way SJ, Shayan A (1989) Early hydration of a Portland cement in water and sodium hydroxide solutions: composition of solutions and nature of solid phases. Cem Concr Res 19:759–769

Longuet P, Burglen L, Zelwer A (1973) La phase liquide du ciment hydraté. Revue des Matériaux de Construction 676:35–41

Barneyback RS, Diamond S (1981) Expression and analysis of pore fluids of hardened cement pastes and mortars. Cem Concr Res 11:279–285

Diamond S (1981) Effects of two Danish flyashes on alkali contents or pore solutions of cement-flyash pastes. Cem Concr Res 11:383–394

Gunkel P (1983) Die Zusammensetzung der flüssigen Phase erstarrender und erhärtender Zemente. Beton-Informationen 23(1):3–8

Diamond S, Ong S (1994) Effects of added alkali hydroxides in mix water on long-term SO4 2− concentrations in pore solution. Cem Concr Comp 16(3):219–226

Goñi S, Lorenzo MP, Guerrero A, Hernández MS (1996) Calcium hydroxide saturation factors in the pore solution of hydrated Portland cement fly ash pastes. J Am Ceram Soc 79(4):1041–1046

Thomas JJ, Rothstein D, Jennings HM, Christensen BJ (2003) Effect of hydration temperature on the solubility behavior of Ca-, S-, Al-, and Si-bearing solid phases in Portland cement pastes. Cem Concr Res 33(12):2037–2047

Lothenbach B, Winnefeld F, Alder C, Wieland E, Lunk P (2007) Effect of temperature on the pore solution, microstructure and hydration products of Portland cement pastes. Cem Concr Res 37(4):483–491

Schwarz W (1995) Novel cement matrices by accelerated hydration of the ferrite phase in Portland cement via chemical activation: kinetics and cementitious properties. Adv Cem Bas Mat 2:189–200

Wieker W, Bade T, Winkler A, Herr R (1991) On the composition of pore solutions squeezed from autoclaved cement pastes. In: Nonat A, Mutin JC (eds) Proceedings of the International RILEM workshop hydration setting Dijon, 3–5 July 1991. E & FN Spon, London, pp 125–135

Christensen AN, Jensen TR, Hanson JC (2004) Formation of ettringite, Ca6Al2(SO4)3(OH)12·26H2O, AFt, and monosulfate, Ca4Al2O6(SO4)·14H2O, AFm-14, in hydrothermal hydration of Portland cement and of calcium aluminum oxide–calcium sulfate dihydrate mixtures studied by in situ synchrotron X-ray powder diffraction. J Solid State Chem 177(6):1944–1951

Glasser FP, Luke K, Angus MJ (1988) Modification of cement pore fluid compositions by pozzolanic additives. Cem Concr Res 18(2):165–178

Lorenzo P, Goñi S, Hernandez S, Guerrero A (1996) Effect of fly ashes with high alkali content on the alkalinity of the pore solution of hydrated Portland cement paste. J Am Ceram Soc 79(2):470–474

Shehata MH, Thomas MDA, Bleszynski RF (1999) The effects of fly ash composition on the chemistry of the pore solution in hydrated cement pastes. Cem Concr Res 29(12):1915–1920

Shehata MH, Thomas MDA (2002) Use of ternary blends containing silica fume and fly ash to suppress expansion due to alkali-silica reaction in concrete. Cem Concr Res 32(3):341–349

Larbi JA, Fraay ALA, Bijen JMJM (1990) The chemistry of the pore fluid of silica fume-blended cement systems. Cem Concr Res 20:506–516

Rasheeduzzafar, Hussain ES (1991) Effect of microsilica and blast furnace slag on pore solution composition and alkali-silica reaction. Cem Concr Comp 13:219–225

Coleman NJ, Page CL (1997) Aspects of the pore solution chemistry of hydrated cement pastes containing metakaolin. Cem Concr Res 27(1):147–154

Tishmack JK, Olek J, Diamond S, Sahu S (2001) Characterization of pore solutions expressed from high-calcium fly-ash-water pastes. Fuel 80:815–819

Vernet C (1982) Comportement de l’ion S–au cours de l’hydratation des ciments riche en laitier (CLK). Silicates industriels 47:85–89

Matschei T, Bellmann F, Stark J (2005) Hydration behaviour of sulphate-activated slag cements. Adv Cem Res 17(4):167–178

Gruskovnjak A, Lothenbach B, Winnefeld F, Figi R, Ko SC, Adler M, Mäder U (2008) Hydration mechanisms of supersulphated slag cement. Cem Concr Res 38:983–992

Song SJ, Jennings HM (1999) Pore solution chemistry of alkali-activated ground granulated blast-furnace slag. Cem Concr Res 29(2):159–170

Puertas F, Fernández-Jiménez A, Blanco-Varela MT (2004) Pore solution in alkali-activated slag cement pastes. Relation to the composition and structure of calcium silicate hydrate. Cem Concr Res 34(1):139–148

Gruskovnjak A, Lothenbach B, Holzer L, Figi R, Winnefeld F (2006) Hydration of alkali-activated slag: comparison with ordinary Portland cement. Adv Cem Res 18(3):119–128

Lothenbach B, Gruskovnjak A (2007) Hydration of alkali-activated slag: thermodynamic modelling. Adv Cem Res 19(2):81–92

Koyanagi K (1932) Hydration of aluminous cement. Concrete 40(8):40–46

Winnefeld F, Lothenbach B (2009) Hydration of calcium sulfoaluminate cements: experimental findings and thermodynamic modelling. Cem Concr Res (in press) doi:10.1016/j.cemconres.2009.08.014

Li GS, Walenta G, Gartner E (2007) Formation and hydration of low-CO2 cements based on belite, calcium sulfoaluminate and calcium aluminoferrite. In: Proceedings of the 12th ICCC, Montreal, Canada, 9–12 July 2007, pp TH3-15.3

Chatterji S (1991) On the relevance of expressed liquid analysis to the chemical processes occurring in cement paste. Cem Concr Res 21:269–272

Duchesne J, Bérubé MA (1994) Evaluation of the validity of the pore solution expression method from hardened cement pastes and mortars. Cem Concr Res 24(3):456–462

Tritthart J (1989) Chloride binding in cement—I. Investigations to determine the composition of pore water in hardened cement. Cem Concr Res 19(4):586–594

Bérubé MA, Tremblay C (2004) Chemistry of pore solution expressed under high pressure: influence of various parameters and comparison with the hot-water extraction method. In: Proceedings of the 12th International Conference on Alkali-Aggregate Reaction in Concrete, vol I, Beijing, China, October 15–19, pp 833–842

Lothenbach B, Winnefeld F, Figi R (2007) The influence of superplasticizers on the hydration of Portland cement. In: Proceedings of the 12th ICCC, Montreal, Canada, 9–12 July 2007, pp W1-5.03

Stark J, Möser B, Bellmann F, Rössler C (2006) Thermodynamische Modellierung der Hydratation von OPC. In: Zementhydratation QCD (eds) Proc 16. Internationale Baustofftagung (ibausil), Weimar, Germany, 20–22 September, Tagungsbericht Band 1, pp 1-0047–1-0066

Lothenbach B, Schmidt T, Romer M (2007) Influence of limestone additions on sulfate ingression. In: De Belie N (ed) Proc Workshop on performance of cement-based materials in aggressive aqueous environments: characterization, modelling, test methods and engineering aspects, Ghent, Belgium, Online version on www.rilem.net. PRO 057, E-ISBN: 978-2-35158-059-2, pp 49–56

Bullard JW (2007) A three-dimensional microstructural model of reactions and transport in aqueous mineral systems. Model Simul Mater Sci Eng 15:711–738

Ma W, Brown PW, Shi D (1992) Solubility of Ca(OH)2 and CaSO4·2H2O in the liquid paste from hardened cement paste. Cem Concr Res 22:531–540

Yeboah YD, Saeed MR, Lee AKK (1994) Kinetics of strontium sulfate precipitation from aqueous electrolyte solutions. J Cryst Growth 135:323–330

Knowles-Van Cappellen VL, Van Cappellen P, Tiller CL (1997) Probing the charge of reactive sites at the mineral-water interface: effect of ionic strength on crystal growth kinetics of fluorite. Geochim Cosmochim Acta 61(9):1871–1877

Kuzel H-J, Pöllmann H (1991) Hydration of C3A in the presence of Ca(OH)2, CaSO4·2H2O and CaCO3. Cem Concr Res 21:885–895

Kuzel H, Baier H (1996) Hydration of calcium aluminate cements in the presence of calcium carbonate. Eur J Miner 8:129–141

Bonavetti VL, Rahhal VF, Irassar EF (2001) Studies on the carboaluminate formation in limestone filler-blended cements. Cem Concr Res 31:853–859

Matschei T, Herfort D, Lothenbach B, Glasser FP (2007) Relationship of cement paste mineralogy to porosity and mechanical properties. In: Proc Conference on Modelling of Heterogeneous Materials, Prague, June 25–27

Damidot D, Barnett SJ, Glasser FP, Macphee DE (2004) Investigation of the CaO–Al2O3–SiO2–CaSO4–CaCO3–H2O system at 25°C by thermodynamic calculation. Adv Cem Res 16(2):69–76

Bellmann F, Stark J (2007) Prevention of thaumasite formation in concrete exposed to sulphate attack. Cem Concr Res 37(8):1215–1222

Bellmann F, Stark J (2008) The role of calcium hydroxide in the formation of thaumasite. Cem Concr Res 38(10):1154–1161

Barker AP, Cory HP (1991) The early hydration of limestone-filled cements. In: Swamy RN (ed) Proc blended cements in construction. Elsevier, Sheffield, UK, pp 107–124

Ingram K, Polusny M, Daugherty K, Rowe W (1990) Carboaluminate reactions as influenced by limestone additions. In: Klieger P, Hooton RD (eds) Proc Carbonate Additions to Cement, vol 1064. American Society for Testing and Materials (ASTM STP), Philadelphia, PA, pp 14–23

Bensted J (1980) Some hydration investigations involving Portland cement-effect of calcium carbonate substitution of gypsum. World Cem Technol 11(8):395–406

Matschei T, Lothenbach B, Glasser FP (2007) The AFm phase in Portland cement. Cem Concr Res 37(2):118–130

Glasser FP, Marchand J, Samson E (2008) Durability of concrete: degradation phenomena involving detrimental chemical reactions. Cem Concr Res 38(2):226–246

Atkins M, Glasser FP, Kindness A (1991) Phase relation and solubility modelling in the CaO–SiO2–Al2O3–MgO–SO3–H2O system: for application to blended cements. Mat Res Soc Symp Proc 212:387–394

Gartner E (2004) Industrially interesting approaches to “low-CO2” cements. Cem Concr Res 34:1489–1498

Albert B, Guy B, Damidot D (2006) Water chemical potential: a key parameter to determine the thermodynamic stability of some cement phases in concrete? Cem Concr Res 36:783–790

Acknowledgments

Many thanks to Dmitrii Kulik, who helped me over many years to master GEMS, to Thomas Matschei and Göril Möschner, who worked hard to improve the cement thermodynamic databases and to Urs Berner, Fred Glasser, and Erich Wieland who offered many insights in applications of thermodynamics to cementitious systems. Thanks also to Frank Winnefeld, Ken Snyder, and Pietro Lura, whose comments helped to improve this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lothenbach, B. Thermodynamic equilibrium calculations in cementitious systems. Mater Struct 43, 1413–1433 (2010). https://doi.org/10.1617/s11527-010-9592-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-010-9592-x