Abstract

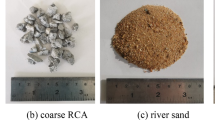

Many environmental problems caused by the large volumes of construction and demolition waste (C&DW), the lack of adequate deposition sites and the shortage of natural resources have led to the use of C&DW as replacement of natural aggregates in the production of new concrete. As in the case of natural aggregates, when recycled aggregates are used to manufacture structural concrete, the assessment of their physical, mechanical and durable characteristics is a key issue. The different physical and mechanical properties of the recycled coarse aggregate (RCA) are evaluated. RCA was obtained by crushing conventional concretes with different strength levels (different w/c ratios) containing four different types of natural coarse aggregates (three crushed stones and a siliceous gravel), which differ in shape, composition and surface texture. There is a significant influence of the natural coarse aggregate (NCA) on the properties of RCA, which in many cases is greater than that of the w/c ratio of the source concrete.

Similar content being viewed by others

References

Zega CJ, Di Maio AA (2007) Efecto del Agregado Grueso Reciclado sobre las Propiedades del Hormigón. Boletín Técnico del Instituto de Materiales y Modelos Estructurales. IMME Venezuela 45(2):1–11

Zega CJ, Taus VL, Villagrán ZYA, Di Maio AA (2005) Comportamiento Físico-Mecánico de Hormigones sometidos a Reciclados Sucesivos. Memorias Symposium fib “Structural Concrete and Time”, La Plata, Argentina, 28–30 September 2005, pp 761–768

Hansen TC (1986) Recycled aggregates and recycled aggregate concrete. Second State-of-the-art. Report developments 1945–1985. RILEM Technical Committee–37-DRC, demolition and recycling of concrete. Mater Struct 19(111):201–246. doi:10.1007/BF02472036

Sri Ravindrarajah R, Tam CT (1985) Properties of concrete made with crushed concrete as coarse aggregate. Mag Concr Res 37(130):29–38

Hansen TC, Narud H (1983) Strength of recycled concrete made from crushed concrete coarse aggregate. Concr Int ACI 5(1):79–83

Van Mier JGM (1997) Fracture processes of concrete, CRC Press, USA, 448 p, Chap 2, pp 17–53

Mehta PK, Monteiro PJM (1998) Concreto: estructura, propiedades y materiales. Instituto Mexicano del Cemento y del Concreto, A.C., Mexico

Tasong WA, Lynsdale CJ, Cripps JC (1999) Aggregate-cement paste interface: part I. Influence of aggregate geochemistry. Cement Concr Res 29(7):1019–1025. doi:10.1016/S0008-8846(99)00086-1

Tasong WA, Lynsdale CJ, Cripps JC (1998) Aggregate-cement paste interface: part II. Influence of aggregate physical properties. Cement Concr Res 28(10):1453–1465. doi:10.1016/S0008-8846(98)00126-4

Giaccio G, Zerbino R (1998) Failure mechanism of concrete: combined effects of coarse aggregates and strength level. Adv Cement Based Mater, USA, vol 7(1), pp 41–48

Reglamento CIRSOC-201. Proyecto, Cálculo y Ejecución de Estructuras de Hormigón Armado y Pretensado. Tomo I. Instituto Nacional de Tecnología Industrial, Argentina

Di Maio A, Gutierrez F, Traversa LP (2001) Comportamiento Físico-Mecánico de Hormigones Elaborados con Agregados Reciclados. Memorias 14º Reunión Técnica de la Asociación Argentina de Tecnología del Hormigón, October 2001, Olavarría, Argentina, pp 37–44

Tavakoli M, Soroushian P (1996) Strengths of recycled aggregate concrete made using field-demolished concrete as aggregate. Mater J, ACI, March–April 1996, pp 182–190

Hasaba S, Kawamura M, Torik K, Takemoto K (1986) Drying shrinkage and durability of the concrete made of recycled concrete aggregate. Trans Japan Concr Inst, vol 3, 1981, pp 55–60 (Cited in [3])

Czarnecka ET, Gillott JE (1982) Effect of different types of crushers on shape and roughness of aggregates. Cement Concr Aggreg 4(1):33–38

Bouquety MN, Descantes Y, Barcelo L, de Larrard F, Clavaud B (2007) Experimental study of crushed aggregate shape. Construct Build Mater 21(4):865–872. doi:10.1016/j.conbuildmat.2005.12.013

Neville AM (1977) Tecnología del Concreto. Tomo I. Instituto Mexicano del Cemento y del Concreto, A.C., Mexico

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zega, C.J., Villagrán-Zaccardi, Y.A. & Di Maio, A.A. Effect of natural coarse aggregate type on the physical and mechanical properties of recycled coarse aggregates. Mater Struct 43, 195–202 (2010). https://doi.org/10.1617/s11527-009-9480-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-009-9480-4