Abstract

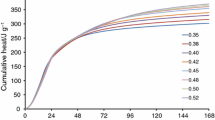

The paper deals with one of the physical methods, which can be used for monitoring hydration of cementitious materials: the radon exhalation method. Experiments with two types of hydrating cement paste (made with water to cement ratios of 0.25 and 0.33) are described. The kinetics of shrinkage and hydration heat development are discussed. Different mechanisms influencing the radon exhalation rate E from cement and hydration products are considered. The initial E-values determined in the beginning of the tests were 0.01–0.02 mBq kg−1 s−1 for the cement pastes made at water/cement ratios of 0.25 and 0.33, respectively. In 3 days both pastes showed E = 0.04 mBq kg−1 s−1. However, the most important finding seems to be the dramatic increase of the radon exhalation rate up to the maximum observed a few hours after mixing with water (0.66 and 0.58 mBq kg−1 s−1 for 0.25 and 0.33 pastes, respectively). This was registered in the radon chamber within the time period usually classified as set. The test results showed a strong correlation between radon exhalation rate and liberation of hydration heat. Peaks of the radon exhalation rate coincide with those of temperature measured on the surface of the cement paste. Analysis of the literature data shows that heating of the materials weakens physical adsorption of radon gas atoms on newly formed solid surfaces and can enhance the radon exhalation rate by several times. However, the performed experiment shows that the radon exhalation rate drastically increases (by dozens of times), and then decreases again. Such a dramatic growth can be explained by a synergy between temperature effect and two more phenomena: (a) intensive formation of microstructure with an extremely high specific surface area, when cement sets and while porosity is still high and (b) intensive flow of water, which traps radon from the newly formed solid surfaces of C-S-H and brings it to the sample surface, enhancing the radon flux.

Similar content being viewed by others

References

Kovler K, Perevalov A, Steiner V, Metzger LA (2005) Radon exhalation of cementitious materials made with coal fly ash: Part 1 – scientific background and testing of the cement and fly ash emanation. J Environ Radioactiv 82:321–334

Stoulos S, Manolopoulou M, Papastefanou C (2004) Measurement of radon emanation factor from granular samples: effects of additives in cement. Appl Radiat Isotopes 60:49–54

Bossew P (2003) The radon emanation power of building materials, soils and rocks. Appl Radiat Isotopes 59:389–392

United Nation Scientific Committee on the Effects of Atomic Radiation (UNSCEAR) (2000) Report to the General Assembly of the United Nations. Annex B. United Nations Sales Publication E.00.IX.3. United Nations, New York

Abumurada KM, Al-Tamimi M (2001) Emanation power of radon and its concentration in soil and rocks. Radiat Measure 34:423–426

Bye GC (1999) Portland cement, 2nd edn. Thomas Telford, London, UK

Balek V, Donhálek J (1982) Radon atoms – a probe of the evolution of the hardened cement paste structure. J␣Mater Sci 17(8):2281–2288

Balek V, Donhálek J (1983) A new method for investigating cement hydration by radioactive indicators. Cem Concrete Res 13:1–6

Balek V, Donhálek J (1992) Radiometric emanation method for monitoring morphology and porosity changes during radwaste cementation. Cem Concrete Res 22:459–464

Balek V, Beckman IN (2002) Theory of emanation thermal analysis. X. Characterization of morphology changes during hydration of cementitious binders. J␣Thermal Anal Calorimetry 67:37–47

Bentz DP, Geiker MR, Hansen KK (2001) Shrinkage-reducing admixtures and early-age desiccation in cement pastes and mortars. Cem Concrete Res 31:1075–1085

Tanner AB (1964) Radon migration in the ground: a review. In: Adams JAS, Lowder WM (eds) Natural radiation environment. Univ. of Chicago Press, Chicago, pp 161–190

Stranden E, Kolstad AK, Lind B (1984) Radon exhalation: moisture and temperature dependence. Health Phys 47:480–484

Petropoulos NP, Anagnostakis MJ, Simopoulos SE (2001) Building materials radon exhalation rate: ERRICCA intercomparison exercise results. Sci Total Environ 272:109–118

Samuelsson C (1990) The closed-can exhalation method for measuring radon. J Res Natl Inst Stand Technol 95(2):167–169

Kovler K (2006) Radon exhalation of hardening concrete: monitoring cement hydration and prediction of radon concentration in construction site. J Environ Radioactiv 86:354–366

Groves-Kirkby CJ, Denman AR, Crockett RGM, Phillips PS, Woolridge AC, Gillmore GK (2006) Time-integrating radon gas measurements in domestic premises: comparison of short-, medium- and long-term exposures. J Environ Radioactiv 86:92–109

Fournier F, Groetz JE, Jacob F, Crolet JM, Lettner H (2005) Simulation of radon transport through building materials: influence of the water content on radon exhalation rate. Transp Porous Med 59:197–214

Mindess S, Young JF (1981) Concrete. Prentice-Hall, Englewood Cliffs, NJ, USA

Winslow D, Diamond S (1974) Specific surface area of hardened Portland cement as determined by SAXS. J␣Am Ceram Soc 57:193–197

Kovler K, Perevalov A, Levit A, Steiner V, Metzger LA (2005) Radon exhalation of cementitious materials made with coal fly ash: Part 2 – testing hardened cement – fly ash pastes. J Environ Radioactiv 82:335–350

Baretto PMC (1975) Radon-222 emanation characteristics of rocks and minerals. In: Radon in uranium mining, panel proceedings, Vienna, IAEA, pp 129–148

Acknowledgments

The author thanks Eng. Andrey Perevalov and Eng. Pavel Larianovsky for the help in the experimental work. The useful comments and advices of Dr. Victor Steiner and Prof. Eugen Rabkin are highly acknowledged. The experimental work has been supported by the Foundation for Promoting Research in the Technion and by E. and J. Bishop Research Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kovler, K. Measurements of radon exhalation rate for monitoring cement hydration. Mater Struct 40, 419–430 (2007). https://doi.org/10.1617/s11527-006-9149-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-006-9149-1