Abstract

A new phase of carbon named Q-carbon is found to be over 40% harder than diamond. This phase is formed by nanosecond laser melting of amorphous carbon and rapid quenching from the super-undercooled state. Closely packed atoms in molten metallic carbon are quenched into Q-carbon with 80-85% sp3 and the rest sp2. The number density of atoms in Q-carbon can vary from 40% to 60% higher than diamond cubic lattice, as the tetrahedra packing efficiency increases from 70% to 80%. Using this semiempirical approach, the corresponding increase in Q-carbon hardness is estimated to vary from 48% to 70% compared to diamond.

Similar content being viewed by others

References

R.S. Ruoff and A.L. Ruoff: Is C60 stifferthan diamond? Nature. 350, 663 (1991).

V. Blank, M. Popov, S. Buga, V. Davydov, V.N. Denisov, A.N. Ivlev, B.N. Marvin, V. Agafonov, R. Ceolin, H. Szwarc, and A. Rassat: Is C60 full -erite harder than diamond? Phys. Lett. A 188, 281 (1994).

A.Y. Liu, M.I. Cohen, and S.H. Tolbert: Prediction of new low compressibility solids. Science 245, 841 (1989).

C. Niu, Y.Z. Lu, and C.M. Lieber: Experimental realization of the covalent solid carbon nitride. Science 261, 334 (1993).

R.B. Kaner, J.J. Gilman, and S.H. Tolbert: Materials science. Designing superhard materials. Science 308, 1268 (2005).

A.Y. Liu and M.I. Cohen: Structural properties and electronic structure of low-compressibility materials: ß-Si3N4 and hypothetical ß-C3N4. Phys. Rev. B. 41, 10727 (1990).

J. Narayan and A. Bhaumik: Novel phase of carbon, ferromagnetism, and conversion into diamond. J. Appl. Phys. 118, 215303 (2015).

J. Narayan and A. Bhaumik: Research update: direct conversion of h-BN into pure c-BN at ambient temperatures and pressures in air. APL Mater. 4, 20701 (2016).

J. Narayan and A. Bhaumik: Q-carbon discovery and formation of single-crystal diamond nano- and microneedles and thin films. Mater. Res. Lett. 4, 118 (2016).

J. Narayan, A. Bhaumik, and W. Xu: Direct conversion of h-BN into c-BN and formation of epitaxial c-BN/diamond heterostructures. J. Appl. Phys. 119, 185302 (2016).

A. Jaoshvili, A. Esakia, M. Porrati, and P.M. Chaikin: Experiments on the random packing of tetrahedral dice. Phys. Rev. Lett. 104, 185501 (2010).

A. Haji-Akbari, M. Engel, A.S. Keys, X. Zheng, R.G. Petschek, P.P. Muhoray, and S.C. Glotzer: Disordered, quasicrystalline and crystalline phases of densely packed tetrahedra. Nature 462, 773 (2009).

Y. Gao, S. Kim, S. Zhou, H.C. Chiu, D. Nelias, C. Berger, W. Heer, L. Polloni, R. Sordan, A. Bongiorno, and E. Riedo: Elastic coupling between layers in two-dimensional materials. Nat. Mater. 14, 714 (2015).

Y. Gao, T. Cao, F. Cellini, C. Berger, W.A. Heer, E. Tosatti, E. Riedo, and A. Bongiorno: Ultrahard carbon film from epitaxial two-layer graphene. Nat. Nanotechnol., 13, 133 (2018).

A. Bhaumik, R. Sachan, and J. Narayan: High-temperature superconductivity in boron-doped Q-carbon. ACS Nano 11, 5351 (2017).

A. Bhaumik, R. Sachan, and J. Narayan: A novel high-temperature carbon-based superconductor: B-doped Q-carbon. J. Appl. Phys. 122, 45301 (2017).

A. Bhaumik, R. Sachan, S. Gupta, and J. Narayan: Discovery of high-temperature superconductivity (TC = 55K) in B-doped Q-carbon. ACS Nano 11, 11915 (2017).

J.R. Willis: Hertzian contact of anisotropic bodies. J. Mech. Phys. Solids. 14, 163 (1966).

J. Narayan, A. Bhaumik, and R. Sachan: High temperature superconductivity in distinct phases of amorphous B-doped Q-carbon. J. Appl. Phys. (2018).

J. Bruley, D.B. Williams, J.J. Cuomo, and D.P. Pappas: Quantitative near-edge structure analysis of diamond-like carbon in the electron microscope using a two-window method. J. Microsc. 180, 22 (1995).

S. Prawer and R.J. Nemanich: Raman spectroscopy of diamond and doped diamond. Philos. Trans. A. Math. Phys. Eng. Sci. 362, 2537–2565 (2004).

ACKNOWLEDGMENTS

We are grateful to Fan Family Foundation Distinguished Chair Endowment for J. Narayan. R. Sachan acknowledges the National Academy of Sciences (NAS), USA for awarding the NRC research fellowship. This work was performed under the National Science Foundation (Award number DMR-1735695). We used Analytical Instrumentation Facility (AIF) at North Carolina State University, which is supported by the State of North Carolina. Filippo Cellini and Elisa Riedo acknowledge the support from the Office of Basic Energy Sciences of the US Department of Energy (grant no. DE-SC0016204).

Author information

Authors and Affiliations

Corresponding author

Appendices

Supplementary materials

The supplementary material for this article can be found at https://doi.org/10.1557/mrc.2018.35.

Author contributions

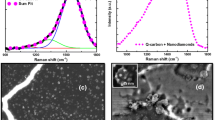

J. N. conceived and designed the theory and wrote the manuscript with inputs from all the co-authors. S. G. and A. B. synthesized the samples and performed the Raman spec-troscopy, SEM, and HR-TEM imaging. R. S. performed electron microscopic imaging and EEL spectroscopy. F. C. and E. R. performed the performed AFM imaging and nanome-chanics experiments.

Competing financial interests statement

The authors declare no competing financial interests.

Conflict of interest

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Narayan, J., Gupta, S., Sachan, R. et al. Q-carbon harder than diamond. MRS Communications 8, 428–436 (2018). https://doi.org/10.1557/mrc.2018.35

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2018.35