Abstract

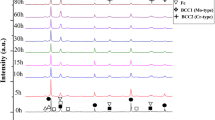

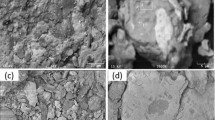

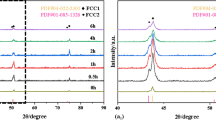

A homogeneous structured CoCrNi medium-entropy alloy was synthesized by gas atomization and spark plasma sintering (SPS). The mechanical properties, corrosion resistance, and magnetic properties were reported in this study. The as-atomized CoCrNi MEA powder, with a spherical morphology in shape and a mean particle diameter of 61 µm, consisted of a single face-centered cubic (FCC) phase with homogeneous distributions of Co, Cr, and Ni elements. Also, the cross-sectional microstructure of powder particles gradually transformed from fully cellular structure into equiaxed-type structure with increasing particle size. After being sintered by SPS, the CoCrNi MEA consisted of a single FCC phase with a mean grain size of 20.8 µm. Meanwhile, the CoCrNi MEA can capable of offering an ultimate tensile strength of 799 MPa, yield strength of 352 MPa, elongation of 53.6%, and hardness of 195.3 HV. In addition, this MEA showed superior corrosion resistance to that of 304 SS (stainless steel) in both 0.5 mol/L HCl and 1 mol/L NaOH solutions. The magnetization loop indicated that this MEA has good soft magnetic properties.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 375, 213 (2004).

T. Yang, Y.L. Zhao, W.H. Liu, J.J. Kai, and C. Liu: L12-strengthened high-entropy alloys for advanced structural applications. J. Mater. Res. 33, 2983 (2018).

R.D. Li, P.D. Niu, T.C. Yuan, P. Cao, and C. Chen: Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloys Compd. 746, 125 (2018).

Y. Shi, L. Collins, R. Feng, C. Zhang, and N. Balke: Homogenization of AlxCoCrFeNi high-entropy alloys with improved corrosion resistance. Corros. Sci. 133, 120 (2018).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, and E.P. George: A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153 (2014).

F. Zhang, C. Zhang, S.L. Chen, J. Zhu, and W.S. Cao: An understanding of high entropy alloys from phase diagram calculations. Calphad 45, 1 (2014).

A. Gail and E.P. George: Tensile properties of high- and medium-entropy alloys. Intermetallics 39, 74 (2013).

Z.G. Wu, W. Guo, K. Jin, and J.D. Poplawsky: Enhanced strength and ductility of a tungsten-doped CoCrNi medium-entropy alloy. J. Mater. Res. 33, 3301 (2018).

J.Y. Wang, H.L. Yang, Z.L. Liu, S.X. Ji, R.D. Li, and J.M. Ruan: A novel Fe40Mn40Cr10Co10/SiC medium-entropy nanocomposite reinforced by the nanoparticles-woven architectural structures. J. Alloys Compd. 772, 272 (2019).

B. Gludovatz, A. Hohenwarter, K.V.S. Thurston, H. Bei, and Z. Wu: Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7, 10602 (2016).

Y.L. Zhao, T. Yang, Y. Tong, J. Wang, and J.H. Luan: Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 138, 72 (2017).

Y. Ma, F. Yuan, M. Yang, P. Jiang, and E. Ma: Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures. Acta Mater. 148, 407 (2018).

J. Miao, C.E. Slone, T.M. Smith, C. Niu, and H. Bei: The evolution of the deformation substructure in a Ni–Co–Cr equiatomic solid solution alloy. Acta Mater. 132, 35 (2017).

M.P. Agustianingrum, S. Yoshida, N. Tsuji, and N. Park: Effect of aluminum addition on solid solution strengthening in CoCrNi medium-entropy alloy. J. Alloys Compd. 781, 866 (2019).

I. Moravcik, J. Cizek, Z. Kovacova, J. Nejezchlebova, and M. Kitzmantel: Mechanical and microstructural characterization of powder metallurgy CoCrNi medium entropy alloy. Mater. Sci. Eng., A 701, 370 (2017).

G. Laplanche, A. Kostka, C. Reinhart, and J. Hunfeld: Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 128, 292 (2017).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan: Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227 (2016).

J. Wang, T. Guo, J. Li, W. Jia, and H. Kou: Microstructure and mechanical properties of non-equilibrium solidified CoCrFeNi high entropy alloy. Mater. Chem. Phys. 210, 192 (2018).

J.B. Seol, J.W. Bae, Z. Li, J.C. Han, and J.G. Kim: Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 151, 366 (2018).

Y. Chew, G.J. Bi, Z.G. Zhu, F.L. Ng, and F. Weng: Microstructure and enhanced strength of laser aided additive manufactured CoCrFeNiMn high entropy alloy. Mater. Sci. Eng., A 744, 137 (2019).

Z.G. Zhu, Q.B. Nguyen, F.L. Ng, X.H. An, X.Z. Liao, and P.K. Liaw: Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr. Mater. 154, 20 (2018).

J. Joseph, P. Hodgson, T. Jarvis, X.H. Wu, and N. Stanford: Effect of hot isostatic pressing on the microstructure and mechanical properties of additive manufactured AlxCoCrFeNi high entropy alloys. Mater. Sci. Eng., A 733, 59 (2018).

W. Hao, H. Zhou, F. Fang, X. Hu, and Z. Xie: Strain-rate effect upon the tensile behavior of CoCrFeNi high-entropy alloys. Mater. Sci. Eng., A 689, 366 (2017).

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, and A. Kostka: Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 94, 124 (2015).

T. Bhattachajee, R. Zheng, Y. Chong, S. Sheikh, and S. Guo: Effect of low temperature on tensile properties of AlCoCrFeNi2.1 eutectic high entropy alloy. Mater. Chem. Phys. 210, 207 (2018).

D. Li, C. Li, T. Feng, Y. Zhang, and G. Sha: High-entropy Al0.3CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 123, 285 (2017).

M.S. Lucas, L. Mauger, J.A. Munoz, and Y. Xiao: Magnetic and vibrational properties of high-entropy alloys. J. Appl. Phys. 109, 299 (2011).

W. Ji, W. Wang, H. Wang, J. Zhang, and Y. Wang: Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetalllics 56, 24 (2015).

Y. Zhang, T.T. Zuo, Y.Q. Cheng, and P.K. Liaw: High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 3, 1455 (2013).

A.Z. Arsad and N.B. Ibrahim: Temperature-dependent magnetic properties of YIG thin films with grain size less 12nm prepared by a sol–gel method. J. Magn. Magn. Mater. 15, 70 (2018).

X.W. Qiu, Y.P. Zhang, and C.G. Liu: Effect of Ti content on structure and properties of Al2CrFeNiCoCuTix high-entropy alloy coatings. J. Alloys Compd. 585, 282 (2014).

X.W. Qiu, Y.P. Zhang, L. He, and C.G. Liu: Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy. J. Alloys Compd. 549, 195 (2013).

C.A.D. Rovere, J.H. Alano, R. Silva, P.A.P. Nascente, and J. Otubo: Characterization of passive films on shape memory stainless steels. Corros. Sci. 57, 154 (2012).

Acknowledgments

This project was financially supported by National Natural Science Foundation of China with No. 51404302.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Yang, H., Ruan, J. et al. Microstructure and properties of CoCrNi medium-entropy alloy produced by gas atomization and spark plasma sintering. Journal of Materials Research 34, 2126–2136 (2019). https://doi.org/10.1557/jmr.2019.96

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.96