Abstract

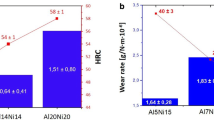

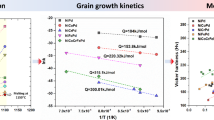

In this paper, the hardness and Young’s moduli along the diffusion paths in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) binary diffusion couples were measured by using the nanoindentation technique. Hardness increases gradually from the pure Ni to the fcc Ni–X alloys, except for the Ni–Os system. While the Young’ moduli in fcc Ni–X alloys scatter much larger and do not show noticeable variation with the addition of element X. After that, the CALPHAD models for description of the composition-dependent hardness and Young’s modulus were proposed, and an in-house code was developed. Based on the present experimental data, the CALPHAD-type descriptions for hardness and Young’s modulus in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) systems were obtained. The model-predicted hardness and Young’s moduli of composition dependence agree with the experimental data in general. It is anticipated that the presently obtained CALPHAD-type hardness and Young’s modulus descriptions, together with the previous thermodynamic and atomic mobility databases, can be used for the future alloy design of novel Ni-based superalloys.

Similar content being viewed by others

References

Ł. Rakoczy, G. Cempura, A. Kruk, A. Czyrska-Filemonowicz, and A. Zielińska-Lipiec: Evolution of γ′ morphology and γ/γ′ lattice parameter misfit in a nickel-based superalloy during non-equilibrium cooling. J. Mater. Res. 110, 66 (2019).

M. Huo, L. Liu, W.C. Yang, Y.F. Li, S.S. Hu, H.J. Su, J. Zhang, and H.Z. Fu: Formation of low-angle grain boundaries under different solidification conditions in the rejoined platforms of Ni-based single crystal superalloys. J. Mater. Res. 34, 251 (2019).

W.J. Sun, S. Kothari, and C.C. Sun: The relationship among tensile strength, Young’s modulus, and indentation hardness of pharmaceutical compacts. Powder Technol. 331, 1 (2018).

M. Liu, J.Y. Lin, C. Lu, K.A. Tieu, K. Zhou, and T. Koseki: Progress in indentation study of materials via both experimental and numerical methods. Crystals 7, 258 (2017).

J.C. Zhao, M.R. Jackson, L.A. Peluso, and L.N. Brewer: A diffusion-multiple approach for mapping phase diagrams, hardness, and elastic modulus. JOM 54, 42 (2002).

L. You and X.P. Song: First principles study of low Young’s modulus Ti–Nb–Zr alloy system. Mater. Lett. 80, 165 (2012).

R.M. Hu, Z.B. Zhou, X.L. Zhou, J. Yu, and K.H. Zhang: Phase stability, electronic structure, elastic properties and hardness of Ru–Ir alloys: First-principles calculations. Mater. Res. Express 4, 076512 (2017).

X. Li, X.Q. Tu, B.Q. Liu, J.M. Song, W. Luo, Y. Lei, G.A. Sun, B. Chen, and Q.M. Hu: Composition-dependent elastic properties in Ti–Ni–Nb from first principle calculations. J. Alloys Compd. 706, 260 (2017).

S.Y. Wen, Y. Tang, J. Zhong, L.J. Zhang, Y. Du, and F. Zheng: High-throughput measurements of interdiffusivity matrices in face centered cubic Ni–Al–Mo alloys at 1273–1473 K. J. Mater. Res. 32, 2188 (2017).

J. Chen, C. Zhang, J. Wang, W.M. Chen, Y. Tang, L.J. Zhang, and Y. Du: Thermodynamic description, diffusivities and atomic mobilities in binary Ni–Os system. Calphad 50, 118 (2015).

L. Kaufman and H. Bernstein: Computer Calculation of Phase Diagrams (Academic Press, New York, 1970).

L.J. Zhang, J. Wang, Y. Du, R. Hu, P. Nash, X.G. Lu, and C. Jiang: Thermodynamic properties of the Al–Fe–Ni system acquired via a hybrid approach combining calorimetry, first-principles and CALPHAD. Acta Mater. 57, 5324 (2009).

L.J. Zhang, Y. Du, I. Steinbach, Q. Chen, and B. Huang: Diffusivities of an Al–Fe–Ni melt and their effects on the microstructure during solidification. Acta Mater. 58, 3664 (2010).

Available at: https://www.thermocalc.com/products-services/databases (accessed April 10, 2019).

Z.K. Liu, H. Zhang, S. Ganeshan, Y. Wang, and S.N. Mathaudhu: Computational modeling of effects of alloying elements on elastic coefficients. Scr. Mater. 63, 686 (2010).

X.G. Lu, M. Selleby, and B. Sundman: Assessments of molar volume and thermal expansion for selected bcc, fcc and hcp metallic elements. Calphad 29, 68 (2005).

A.E. Gheribi and P. Chartrand: Application of the CALPHAD method to predict the thermal conductivity in dielectric and semiconductor crystals. Calphad 39, 70 (2012).

X.T. Liu and K. Oikawa: Assessment of the temperature and pressure dependence of molar volume and phase diagrams of Cu and Zn. Calphad 47, 114 (2014).

L.J. Zhang, M. Stratmann, Y. Du, B. Sundman, and I. Steinbach: Incorporating the CALPHAD sublattice approach of ordering into the phase-field model with finite interface dissipation. Acta Mater. 88, 156 (2015).

J. Chen, L.J. Zhang, and X.G. Lu: Screening of possible Re-substitutional elements in single-crystal Ni-based superalloys: A viewpoint from interdiffusion coefficients in Ni–Al–X ternaries. Metall. Mater. Trans. A 49A, 2999 (2018).

J. Chen, J.K. Xiao, L. Zhang, and Y. Du: Interdiffusion in fcc Ni–X (X = Rh, Ta, W, Re, and Ir) alloys. J. Alloys Compd. 657, 457 (2016).

Y. Lin, M. Wei, G.D. Li, and L.J. Zhang: Phase equilibria and microhardness of as-cast and annealed Ni–Al–Os alloys in Ni-rich region. J. Phase Equilib. Diffus. 39, 944 (2018).

J. Chen, J.R. Zhao, L.J. Zhang, X-G. Lu, and L. Liu: Atomic mobilities in fcc Ni-rich Ni–X (X = Rh, Ta, W, Re, and Ir) systems. Calphad 65, 316 (2019).

S.H. Zhou, Y. Wang, L.Q. Chen, Z.K. Liu, and R.E. Napolitano: Solution-based thermodynamic modeling of the Ni–Ta and Ni–Mo–Ta systems using first-principle calculations. Calphad 33, 631 (2009).

P. Gustafson: A thermodynamic evaluation of the Cr–Ni–W system. Calphad 12, 277 (1988).

K. Yaqoob and J.M. Joubert: Experimental determination and thermodynamic modeling of the Ni–Re binary system. J. Solid State Chem. 196, 320 (2012).

K. Durst, O. Franke, A. Böhner, and M. Göken: Indentation size effect in Ni–Fe solid solutions. Acta Mater. 55, 6825 (2007).

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, and S. Suresh: Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159 (2003).

C.H. Wang, T.H. Fang, P.C. Cheng, C.C. Chiang, and K.C. Chao: Simulation and experimental analysis of nanoindentation and mechanical properties of amorphous NiAl alloys. J. Mol. Model. 21, 1 (2015).

V. Petley, S. Sathishkumar, K.H.T. Raman, G.M. Rao, and U. Chandrasekhar: Microstructural and mechanical characteristics of Ni–Cr thin films. Mater. Res. Bull. 66, 59 (2015).

S.H. Kim: Young’s Modulus Measurement of Electroplated Nickel Using AFM (2006 ASME International Mechanical Engineering Congress and Exposition, Chicago, Illinois, 2006).

O. Hubert, X. Milhet, P. Gadaud, M. Tatat, P.O. Renault, and C. Coupeau: Modeling of Young’s modulus variations with temperature of Ni and oxidized Ni using a magneto-mechanical approach. Mater. Sci. Eng., A 633, 76 (2015).

W. Köster: Temperaturabhangigkeit des Elastizitatsmoduls reiner Metalle. Z. Metallkd. 39, 1 (1948).

K. Honda and T. Terada: On the change of elastic constants of ferromagnetic substances by magnetization. Tokyo Sugaku-Butsurigakukwai Kiji-Gaiyo 2, 381 (1905).

N. Kurnakow and J. Rapke: Harte und Elastizitatsmodul isomorpher Gemische von Kupfer mit Nickel. Z. Anorg. Chem. 87, 269 (1914).

W.A. Mudge and L.W. Luff: Some mechanical properties of nickel, manganese–nickel and copper–nickel alloys. Am. Soc. Test. Mater., Proc. 28, 278 (1928).

A. Jacquerod and H. Mügeli: Etude sur l’élasticité de flexion: Fer–cuivre–or–argent–platine–verre de silice–nickel. Helv. Phys. Acta 4, 3 (1931).

K. Nakamura: Unterschung der Variationen des Elastizitatskoeffizienten der Metallegierung Ni–Fe durch Magnetisierung. Z. Phys. 94, 707 (1935).

R.M. Davies and I.H. Thomas: A dynamical method for the measurement of Young’s modulus for imperfectly elastic metals, and the application of the method to nickel and some of its alloys. Philos. Mag. 23, 361 (1937).

O. Engler: Der Elastizitätsmodul ferromagnetischer Stoffe in Abhängigkeit von der Temperatur und vom Magnetfeld. Ann. Phys. 423, 145 (1938).

R.I. Kimura: On the elastic moduli of ferromagnetic materials. Part I. Dynamical measurements of the elastic moduli of iron crystals. Proc. Phys.-Math. Soc. Jpn. 21, 686 (1939).

M. Yamamoto: Young’s modulus of elasticity and its variation with magnetization in ferromagnetic nickel–copper alloys. Nippon Kinzoku Gakkaishi 6, 249 (1942).

M. Yamamoto: On the ΔE-effect of iron, nickel and cobalt. Nippon Kinzoku Gakkaishi 5, 167 (1941).

H. Masumoto and H. Saito: On elasticity, its temperature coefficient, and heat expansion coefficient of the nickel–copper alloy system. Nippon Kinzoku Gakkaishi 8, 49 (1944).

H. M. Ledbetter and R. P. Reed: Elastic properties of metals and alloys. I. Iron, Nickel, and Iron–Nickel Alloys. J. Phys. Chern. Ref. Data 2, 531 (1973).

V.A. Pavlov, N.F. Kriutchkov, and I.D. Fedotov: Relationship of temperature to elastic modulus in nickel–copper alloys. Phys. Met. Metallogr. 5, 160 (1957).

W.H. Hill, K.D. Shimmin, and B.A. Wilcox: Elevated temperature dynamic moduli of metallic materials. Am. Soc. Test. Mater., Proc. 61, 890 (1961).

Y. Tino and T. Maeda: On the anomalous thermoelastic variation in the invar-type iron–nickel alloys. J. Phys. Soc. Jpn. 18, 955 (1963).

A.F. Orlov and S.G. Fedotov: Temperature dependence of the Young’s and shear moduli of Ni–Cu alloys. Phys. Met. Metallogr. 22, 146 (1966).

G. Faninger: Die elastischen konstanten von Kupfer·Nickel-Vielkristallen. Z. Metallkd. 60, 601 (1969).

H. Masumoto, H. Saitô, and S. Sawaya: Thermal expansion and temperature dependence of Young’s modulus of nickel-copper alloys. Trans. Jpn. Inst. Met. 11, 88 (1970).

J. Merker, D. Lupton, M. Töpfer, and H. Knake: High temperature mechanical properties of the platinum group metals. Platinum Met. Rev. 45, 74 (2001).

S.L. Shang, A. Saengdeejing, Z.G. Mei, D.E. Kim, H. Zhang, S. Ganeshan, Y. Wang, and Z.K. Liu: First-principles calculations of pure elements: Equations of state and elastic stiffness constants. Comput. Mater. Sci. 48, 813 (2010).

S.L. Shang, D.E. Kim, C.L. Zacherl, Y. Wang, Y. Du, and Z.K. Liu: Effects of alloying elements and temperature on the elastic properties of dilute Ni-base superalloys from first-principles calculations. J. Appl. Phys. 112, 053515 (2012).

D. Kim, S.L. Shang, and Z.K. Liu: Effects of alloying elements on elastic properties of Ni by first-principles calculations. Comput. Mater. Sci. 47, 254 (2009).

R. Hill: The elastic behaviour of a crystalline aggregate. Proc. Phys. Soc., London, Sect. A 65, 349 (1952).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

Acknowledgments

The financial support from the Youth Talent Project of Innovation-driven Plan at Central South University (Grant No. 2019CX027), the Hunan Provincial Science and Technology Program of China (Grant No. 2017RS3002)—Huxiang Youth Talent Plan, Project Funded by China Postdoctoral Science Foundation (Grant No. 2018M640526), Jiangsu Planned Projects for Postdoctoral Research Funds (Grant No. 2018K073C) and Lvyangjinfeng Talent Program of Yangzhou are acknowledged. Lijun Zhang acknowledges the project supported by the State Key Laboratory of Powder Metallurgy Foundation, Central South University, Changsha, China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, J., Zhang, L. Composition-dependent hardness and Young’s modulus in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) alloys: Experimental measurements and CALPHAD modeling. Journal of Materials Research 34, 3104–3115 (2019). https://doi.org/10.1557/jmr.2019.220

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.220