Abstract

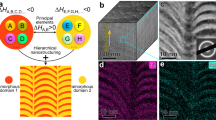

Intrinsic size effects in nanoglass plasticity have been connected to the structural length scales imposed by the interfacial network, and control over this behavior is critical to designing amorphous alloys with improved mechanical response. In this paper, atomistic simulations are employed to probe strain delocalization in nanoglasses with explicit correlation to the interfacial characteristics and length scales of the amorphous grain structure. We show that strength is independent of grain size under certain conditions, but scales with the excess free volume and degree of short-range ordering in the interfaces. Structural homogenization upon annealing of the nanoglasses increases their strength toward the value of the bulk metallic glass; however, continued partitioning of strain to the interfacial regions inhibits the formation of a primary shear band. Intrinsic size effects in nanoglass plasticity thus originate from biased plastic strain accumulation within the interfacial regions, which will ultimately govern strain delocalization and homogenous flow in nanoglasses.

Similar content being viewed by others

References

J. Jing, A. Kramer, R. Birringer, H. Gleiter, and U. Gonser: Modified atomic-structure in a Pd–Fe–Si nanoglass—A mossbauer study. J. Non-Cryst. Solids 113, 167 (1989).

H. Gleiter: Nanoglasses: A new kind of noncrystalline materials. Beilstein J. Nanotechnol. 4, 517 (2013).

J.X. Fang, U. Vainio, W. Puff, R. Wurschum, X.L. Wang, D. Wang, M. Ghafari, F. Jiang, J. Sun, H. Hahn, and H. Gleiter: Atomic structure and structural stability of Sc75Fe25 nanoglasses. Nano Lett. 12, 458 (2012).

N. Chen, D.V. Louzguine-Luzgin, G.Q. Xie, P. Sharma, J.H. Perepezko, M. Esashi, A.R. Yavari, and A. Inoue: Structural investigation and mechanical properties of a representative of a new class of materials: Nanograined metallic glasses. Nanotechnology 24, 045610 (2013).

N. Chen, R. Frank, N. Asao, D.V. Louzguine-Luzgin, P. Sharma, J.Q. Wang, G.Q. Xie, Y. Ishikawa, N. Hatakeyama, Y.C. Lin, M. Esashi, Y. Yamamoto, and A. Inoue: Formation and properties of Au-based nanograined metallic glasses. Acta Mater. 59, 6433 (2011).

C. Guo, Y. Fang, B. Wu, S. Lan, G. Peng, X-l. Wang, H. Hahn, H. Gleiter, and T. Feng: Ni–P nanoglass prepared by multi-phase pulsed electrodeposition. Mater. Res. Lett. 5, 293 (2017).

Q.P. Cao, J.W. Liu, K.J. Yang, F. Xu, Z.Q. Yao, A. Minkow, H.J. Fecht, J. Ivanisenko, L.Y. Chen, X.D. Wang, S.X. Qu, and J.Z. Jiang: Effect of pre-existing shear bands on the tensile mechanical properties of a bulk metallic glass. Acta Mater. 58, 1276 (2010).

H. Shao, Y. Xu, B. Shi, C. Yu, H. Hahn, H. Gleiter, and J. Li: High density of shear bands and enhanced free volume induced in Zr70Cu20Ni10 metallic glass by high-energy ball milling. J. Alloys Compd. 548, 77 (2013).

Y. Ritter, D. Sopu, H. Gleiter, and K. Albe: Structure, stability and mechanical properties of internal interfaces in Cu64Zr36 nanoglasses studied by MD simulations. Acta Mater. 59, 6588 (2011).

O. Adjaoud and K. Albe: Interfaces and interphases in nanoglasses: Surface segregation effects and their implications on structural properties. Acta Mater. 113, 284 (2016).

O. Adjaoud and K. Albe: Microstructure formation of metallic nanoglasses: Insights from molecular dynamics simulations. Acta Mater. 145, 322 (2018).

R. Witte, T. Feng, J.X. Fang, A. Fischer, M. Ghafari, R. Kruk, R.A. Brand, D. Wang, H. Hahn, and H. Gleiter: Evidence for enhanced ferromagnetism in an iron-based nanoglass. Appl. Phys. Lett. 103, 073106 (2013).

N. Chen, D. Wang, T. Feng, R. Kruk, K-F. Yao, D.V. Louzguine-Luzgin, H. Hahn, and H. Gleiter: A nanoglass alloying immiscible Fe and Cu at the nanoscale. Nanoscale 7, 6607 (2015).

J.Q. Wang, N. Chen, P. Liu, Z. Wang, D.V. Louzguine-Luzgin, M.W. Chen, and J.H. Perepezko: The ultrastable kinetic behavior of an Au-based nanoglass. Acta Mater. 79, 30 (2014).

X.L. Wang, F. Jiang, H. Hahn, J. Li, H. Gleiter, J. Sun, and J.X. Fang: Plasticity of a scandium-based nanoglass. Scr. Mater. 98, 40 (2015).

F.C. Li, T.Y. Wang, Q.F. He, B.A. Sun, C.Y. Guo, T. Feng, and Y. Yang: Micromechanical mechanism of yielding in dual nano-phase metallic glass. Scr. Mater. 154, 186 (2018).

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty: Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067 (2007).

H. Gleiter, T. Schimmel, and H. Hahn: Nanostructured solids—From nano-glasses to quantum transistors. Nano Today 9, 17 (2014).

C.A. Schuh and T.G. Nieh: A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 51, 87 (2003).

D. Sopu, Y. Ritter, H. Gleiter, and K. Albe: Deformation behavior of bulk and nanostructured metallic glasses studied via molecular dynamics simulations. Phys. Rev. B 83, 100202 (2011).

S. Adibi, P.S. Branicio, Y-W. Zhang, and S.P. Joshi: Composition and grain size effects on the structural and mechanical properties of CuZr nanoglasses. J. Appl. Phys. 116, 043522 (2014).

B. Cheng and J.R. Trelewicz: Controlling interface structure in nanoglasses produced through hydrostatic compression of amorphous nanoparticles. Phys. Rev. Mater. 3, 035602 (2019).

C.C. Wang, J. Ding, Y.Q. Cheng, J.C. Wan, L. Tian, J. Sun, Z.W. Shan, J. Li, and E. Ma: Sample size matters for Al88Fe7Gd5 metallic glass: Smaller is stronger. Acta Mater. 60, 5370 (2012).

M. Ghidelli, S. Gravier, J.J. Blandin, P. Djemia, F. Mompiou, G. Abadias, J.P. Raskin, and T. Pardoen: Extrinsic mechanical size effects in thin ZrNi metallic glass films. Acta Mater. 90, 232 (2015).

G. Kumar, A. Desai, and J. Schroers: Bulk metallic glass: The smaller the better. Adv. Mater. 23, 461 (2011).

X. Wang, F. Jiang, H. Hahn, J. Li, H. Gleiter, J. Sun, and J. Fang: Sample size effects on strength and deformation mechanism of Sc75Fe25 nanoglass and metallic glass. Scr. Mater. 116, 95 (2016).

D. Şopu and K. Albe: Influence of grain size and composition, topology and excess free volume on the deformation behavior of Cu–Zr nanoglasses. Beilstein J. Nanotechnol. 6, 537 (2015).

S. Adibi, Z-D. Sha, P.S. Branicio, S.P. Joshi, Z-S. Liu, and Y-W. Zhang: A transition from localized shear banding to homogeneous superplastic flow in nanoglass. Appl. Phys. Lett. 103, 211905 (2013).

S. Adibi, P.S. Branicio, and S.P. Joshi: Suppression of shear banding and transition to necking and homogeneous flow in nanoglass nanopillars. Sci. Rep. 5, 15611 (2015).

O. Franke, D. Leisen, H. Gleiter, and H. Hahn: Thermal and plastic behavior of nanoglasses. J. Mater. Res. 29, 1210 (2014).

E.D. Cubuk, R.J.S. Ivancic, S.S. Schoenholz, D.J. Strickland, A. Basu, Z.S. Davidson, J. Fontaine, J.L. Hor, Y-R. Huang, Y. Jiang, N.C. Keim, K.D. Koshigan, J.A. Lefever, T. Liu, X-G. Ma, D.J. Magagnosc, E. Morrow, C.P. Ortiz, J.M. Rieser, A. Shavit, T. Still, Y. Xu, Y. Zhang, K.N. Nordstrom, P.E. Arratia, R.W. Carpick, D.J. Durian, Z. Fakhraai, D.J. Jerolmack, D. Lee, J. Li, R. Riggleman, K.T. Turner, A.G. Yodh, D.S. Gianola, and A.J. Liu: Structure–property relationships from universal signatures of plasticity in disordered solids. Science 358, 1033 (2017).

Y.Q. Cheng, A.J. Cao, H.W. Sheng, and E. Ma: Local order influences initiation of plastic flow in metallic glass: Effects of alloy composition and sample cooling history. Acta Mater. 56, 5263 (2008).

J. Schiotz, T. Vegge, F.D. Di Tolla, and K.W. Jacobsen: Atomic-scale simulations of the mechanical deformation of nanocrystalline metals. Phys. Rev. B 60, 11971 (1999).

B. Cheng and J.R. Trelewicz: Design of crystalline-amorphous nanolaminates using deformation mechanism maps. Acta Mater. 153, 314 (2018).

A.S. Argon: Plastic deformation in metallic glasses. Acta Metall. 27, 47 (1979).

Y.F. Shi and M.L. Falk: Atomic-scale simulations of strain localization in three-dimensional model amorphous solids. Phys. Rev. B 73, 214201 (2006).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995).

M.I. Mendelev, D.J. Sordelet, and M.J. Kramer: Using atomistic computer simulations to analyze X-ray diffraction data from metallic glasses. J. Appl. Phys. 102, 043501 (2007).

Y.Q. Cheng, H.W. Sheng, and E. Ma: Relationship between structure, dynamics, and mechanical properties in metallic glass-forming alloys. Phys. Rev. B 78, 014207 (2008).

F. Shimizu, S. Ogata, and J. Li: Theory of shear banding in metallic glasses and molecular dynamics calculations. Mater. Trans. 48, 2923 (2007).

Y.Q. Cheng, A.J. Cao, and E. Ma: Correlation between the elastic modulus and the intrinsic plastic behavior of metallic glasses: The roles of atomic configuration and alloy composition. Acta Mater. 57, 3253 (2009).

A. Stukowski: Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010).

Acknowledgments

Support for this work was provided through the National Science Foundation under Award 1554411. The authors would like to thank Stony Brook Research Computing and Cyberinfrastructure and the Institute for Advanced Computational Science at Stony Brook University for access to the high-performance SeaWulf computing system, which was made possible by National Science Foundation Award 1531492. The authors also gratefully acknowledge the use of computing resources at the Center for Functional Nanomaterials, which is a US DOE Office of Science Facility at Brookhaven National Laboratory under Contract No. DE-SC0012704.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, B., Trelewicz, J.R. Interfacial plasticity governs strain delocalization in metallic nanoglasses. Journal of Materials Research 34, 2325–2336 (2019). https://doi.org/10.1557/jmr.2019.101

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.101