Abstract

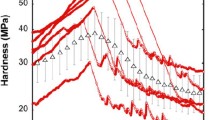

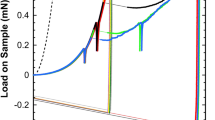

Nanoindentation experiments performed in 5 and 18 μm thick vapor deposited polycrystalline lithium films at 31 °C reveal the mean pressure lithium can support is strongly dependent on length scale and strain rate. At the smallest length scales (indentation depths of 40 nm), the mean pressure lithium can support increases from ∼23 to 175 MPa as the indentation strain rate increases from 0.195 to 1.364 s−1. Furthermore, these pressures are ∼46–350 times higher than the nominal yield strength of bulk polycrystalline lithium. The length scale and strain rate dependent hardness is rationalized using slightly modified forms of the Nabarro–Herring and Harper–Dorn creep mechanisms. Load-displacement curves suggest a stress and length-scale dependent transition from diffusion to dislocation-mediated flow. Collectively, these experimental observations shed significant new light on the mechanical behavior of lithium at the length scale of defects existing at the lithium/solid electrolyte interface.

Similar content being viewed by others

References

E.J. Cheng, A. Sharafi, and J. Sakamoto: Intergranular Li metal propagation through polycrystalline Li6.25Al0.25La3Zr2O12 ceramic electrolyte. Electrochim. Acta 223, 85 (2017).

C. Xu, Z. Ahmad, A. Aryanfar, V. Viswanathan, and J.R. Greer: Enhanced strength and temperature dependence of mechanical properties of Li at small scales and its implications for Li metal anodes. Proc. Natl. Acad. Sci. U.S.A. 114, 57 (2017).

S. Yu, R.D. Schmidt, R. Garcia-Mendez, E. Herbert, N.J. Dudney, J.B. Wolfenstine, and D.J. Siegel: Elastic properties of the solid electrolyte Li7La3Zr2O12 (LLZO). Chem. Mater. 28, 197 (2015).

R. Schultz: Lithium: Measurement of Young’s Modulus and Yield Strength; Technical Report FERMILAB-TM-2191; Fermi National Accelerator Laboratory: Batavia, IL, 2002.

E.G. Herbert, S.A. Hackney, N.J. Dudney, and P.S. Phani: Nanoindentation of high purity vapor deposited lithium films: The elastic modulus. J. Mater. Res. 33, 1335–1346 (2018).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

B.N. Lucas: An experimental investigation of creep and viscoelastic properties using depth-sensing indentation techniques. Ph.D. dissertation, University of Tennessee, Knoxville, 1997.

J.P. Hirth and J. Lothe: Theory of Dislocations, 2nd ed. (John Wiley and Sons, New York, NY, 1982); ch. 17.

G. Feng and A.H.W. Ngan: Creep and strain burst in indium and aluminium during nanoindentation. Scr. Mater. 45, 971 (2001).

J.R. Morris, H. Bei, G.M. Pharr, and E.P. George: Size effects and stochastic behavior of nanoindentation pop in. Phys. Rev. Lett. 106, 165502 (2011).

I.N. Sneddon: The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

E.G. Herbert, S.A. Hackney, N.J. Dudney, V. Thole, and P.S. Phani: Nanoindentation of high purity vapor deposited lithium films: A mechanistic rationalization of the transition from diffusion to dislocation-mediated flow. J. Mater. Res. 33, 1361–1368 (2018).

T.O. Mulhearn and D. Tabor: Creep and hardness of metals: A physical study. J. Inst. Met. 89, 7 (1960).

W.H. Poisl, W.C. Oliver, and B.D. Fabes: The relationship between indentation and uniaxial creep in amorphous selenium. J. Mater. Res. 10, 2024 (1995).

A.F. Bower, N.A. Fleck, A. Needleman, and N. Ogbonna: Indentation of a power law creeping solid. Proc. R. Entomol. Soc. Lond. Ser. A Gen. Entomol. 441, 97 (1993).

C. Su, E.G. Herbert, S. Sohn, J.A. LaManna, W.C. Oliver, and G.M. Pharr: Measurement of power-law creep parameters by instrumented indentation methods. J. Mech. Phys. Solid. 61, 517 (2013).

T.P. Weihs and J.B. Pethica: Monitoring time-dependent deformation in small volumes. Mater. Res. Soc. Symp. Proc. 239, 235 (1991).

W.B. Li and R. Warren: A model for nano-indentation creep. Acta Metall. Mater. 41, 3065 (1993).

S.A. Asif and J.B. Pethica: Nanoindentation creep of single-crystal tungsten and gallium arsenide. Philos. Mag. A 76, 1105 (1997).

H. Li and A.H.W. Ngan: Size effects of nanoindentation creep. J. Mater. Res. 19, 513 (2004).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solid. 46, 411 (1998).

T.G. Langdon: An analysis of flow mechanisms in high temperature creep and superplasticity. Mater. Trans. 46, 1951 (2005).

F.R.N. Nabarro: Report of a Conference on Strength of Solids, Vol. 75 (The Physical Society, London, U.K., 1948).

C. Herring: Diffusional viscosity of a polycrystalline solid. J. Appl. Phys., 21, 437 (1950).

J. Harper and J.E. Dorn: Viscous creep of aluminum near its melting temperature. Acta Metall. 5, 654 (1957).

R.J.D. Tilley: Defects in Solids, Vol. 244 (John Wiley & Sons, Hoboken, New Jersey, 2008).

E.H. Lee and J.R.M. Radok: The contact problem for viscoelastic bodies. J. Appl. Mech. 27, 438 (1960).

T.C.T. Ting: The contact stresses between a rigid indenter and a viscoelastic half-space. J. Appl. Mech. 33, 845 (1966).

D. Tabor: Hardness of Metals (Clarendon Press, Oxford, 1951).

A. Lodding, J.N. Mundy, and A. Ott: Isotope inter-diffusion and self-diffusion in solid lithium metal. Phys. Status Solidi B 38, 559 (1970).

D.A. Porter, K.E. Easterling, and M.Y. Sherif: Phase Transformations in Metals and Alloys, 3rd ed. (CRC Press, London, 2009).

S.G. Corcoran, R.J. Colton, E.T. Lilleodden, and W.W. Gerberich: Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 55, 57 (1997).

G.M. Pharr, E.G. Herbert, and Y. Gao: The indentation size effect: A critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40, 271 (2010).

ACKNOWLEDGMENTS

This research was sponsored jointly by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy’s Advanced Battery Materials Research program (managed by Tien Duong) and by TARDEC, the U.S. Army Tank Automotive Research Development and Engineering Center. E.G.H. is grateful for start-up funding from the Department of Materials Science and Engineering at Michigan Technological University. V.T.’s contributions were financially supported through the MSE Department’s McArthur Internship program. The authors are also grateful for the guidance and input provided by Professor George M. Pharr during the writing of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has been selected as an Invited Feature Paper.

Rights and permissions

About this article

Cite this article

Herbert, E.G., Hackney, S.A., Thole, V. et al. Nanoindentation of high-purity vapor deposited lithium films: A mechanistic rationalization of diffusion-mediated flow. Journal of Materials Research 33, 1347–1360 (2018). https://doi.org/10.1557/jmr.2018.84

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.84