Abstract

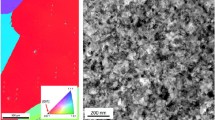

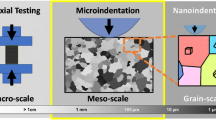

The strain-rate sensitivity of the flow stress represents a crucial parameter for characterizing the deformation kinetics of a material. In this work a new method was developed and validated for determining the local strain-rate sensitivity of the flow stress at different plastic strains. The approach is based on spherical nanoindentation strain-rate jump tests during one deformation experiment. In the case of ultrafine-grained Al and ultrafine-grained Cu good agreement between this technique and macroscopic compression tests has been achieved. In contrast to this, individual spherical nanoindentation experiments at constant strain-rates resulted in unrealistically high strain-rate sensitivities for both materials because of drift influences. Microstructural investigations of the residual spherical imprints on ultrafine-grained Al and ultrafine-grained Cu revealed significant differences regarding the deformation structure. For ultrafine-grained Cu considerably less activity of grain boundary sliding has been observed compared to ultrafine-grained Al.

Similar content being viewed by others

Change history

01 June 2017

An Erratum to this paper has been published: https://doi.org/10.1557/jmr.2017.245

References

R.Z. Valiev, I.V. Alexandrov, Y.T. Zhu, and T.C. Lowe: Paradox of strength and ductility in metals processed by severe plastic deformation. J. Mater. Res. 17, 5–8 (2002).

Z. Horita, K. Ohashi, T. Fujita, K. Kaneko, and T.G. Langdon: Achieving high strength and high ductility in precipitation-hardened alloys. Adv. Mater. 17, 1599–1602 (2005).

H.W. Höppel, J. May, and M. Göken: Enhanced strength and ductility in ultrafine-grained aluminium produced by accumulative roll bonding. Adv. Eng. Mater. 6, 781–784 (2004).

J. Chen, L. Lu, and K. Lu: Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 54, 1913–1918 (2006).

J. May, H.W. Höppel, and M. Göken: Strain rate sensitivity of ultrafine-grained aluminium processed by severe plastic deformation. Scr. Mater. 53, 189–194 (2005).

A. Mishra, M. Martin, N.N. Thadhani, B.K. Kad, E.A. Kenik, and M.A. Meyers: High-strain-rate response of ultra-fine-grained copper. Acta Mater. 56, 2770–2783 (2008).

V. Maier, K. Durst, J. Mueller, B. Backes, H. Höppel, and M. Göken: Nanoindentation strain-rate jump tests for determining the local strain-rate sensitivity in nanocrystalline Ni and ultrafine-grained Al. J. Mater. Res. 26, 1421–1430 (2011).

S. Pathak, D. Stojakovic, and S.R. Kalidindi: Measurement of the local mechanical properties in polycrystalline samples using spherical nanoindentation and orientation imaging microscopy. Acta Mater. 57, 3020–3028 (2009).

S. Pathak, J. Michler, K. Wasmer, and S.R. Kalidindi: Studying grain boundary regions in polycrystalline materials using spherical nano-indentation and orientation imaging microscopy. J. Mater. Sci. 47, 815–823 (2012).

J.G. Swadener, E.P. George, and G.M. Pharr: The correlation of the indentation size effect measured with indenters of various shapes. J. Mech. Phys. Solids 50, 681–694 (2002).

R. Sánchez-Martín, C. Zambaldi, M.T. Pérez-Prado, and J.M. Molina-Aldareguia: High temperature deformation mechanisms in pure magnesium studied by nanoindentation. Scr. Mater. 104, 9–12 (2015).

S.R. Kalidindi and S. Pathak: Determination of the effective zero-point and the extraction of spherical nanoindentation stress–strain curves. Acta Mater. 56, 3523–3532 (2008).

H. Hertz: Über die Berührung fester elastischer Körper [The contact of solid elastic bodies]. J. Für Die Reine Und Angew. Math. 1882, 156–171 (1882).

D. Tabor: The Hardness of Metals (Oxford University Press, London, 1951).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai: Novel ultra-high straining process for bulk materials-development of the accumulative roll-bonding (ARB) process. Acta Mater. 47, 579–583 (1999).

J.B. Pethica and W.C. Oliver: Mechanical properties of nanometer volumes of material: Use of the elastic response of small area indentations. Mater. Res. Soc. Symp. Proc. 130, 13–23 (1989).

E.G. Herbert, G.M. Pharr, W.C. Oliver, B.N. Lucas, and J.L. Hay: On the measurement of stress–strain curves by spherical indentation. Thin Solid Films 398–399, 331–335 (2001).

T.F. Juliano, M.R. Vanlandingham, T. Weerasooriya, and P. Moy: Extracting stress–strain and compressive yield stress information from spherical indentation (Army Research Lab Final Report, Defense Technical Information Center, Fort Belvoir, 2007).

S. Basu, A. Moseson, and M.W. Barsoum: On the determination of spherical nanoindentation stress–strain curves. J. Mater. Res. 21, 2628–2637 (2006).

R.K. Chintapalli, E. Jimenez-Pique, F.G. Marro, H. Yan, M. Reece, and M. Anglada: Spherical instrumented indentation of porous nanocrystalline zirconia. J. Eur. Ceram. Soc. 32, 123–132 (2012).

Y.J. Park and G.M. Pharr: Nanoindentation with spherical indenters: Finite element studies of deformation in the elastic-plastic transition regime. Thin Solid Films 447–448, 246–250 (2004).

Y. Liu, J. Hay, H. Wang, and X. Zhang: A new method for reliable determination of strain-rate sensitivity of low-dimensional metallic materials by using nanoindentation. Scr. Mater. 77, 5–8 (2014).

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma: Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng., A 381, 71–79 (2004).

V. Maier, B. Merle, M. Göken, and K. Durst: An improved long-term nanoindentation creep testing approach for studying the local deformation processes in nanocrystalline metals at room and elevated temperatures. J. Mater. Res. 28, 1177–1188 (2013).

ACKNOWLEDGMENTS

The authors gratefully acknowledge the funding of the German Research Council (DFG) which, within the framework of its “Excellence Initiative”, supports the cluster of excellence “Engineering of Advanced Materials” at the University of Erlangen-Nuremberg.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Feldner, P., Merle, B. & Göken, M. Determination of the strain-rate sensitivity of ultrafine-grained materials by spherical nanoindentation. Journal of Materials Research 32, 1466–1473 (2017). https://doi.org/10.1557/jmr.2017.69

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.69