Abstract

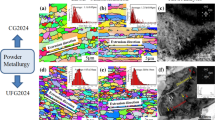

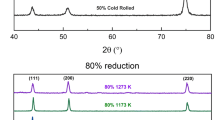

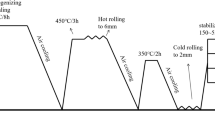

In this paper, we report on the microstructural evolution and mechanical properties of a 5052 Al alloy processed by rotationally accelerated shot peening (RASP). A thick deformation layer of ∼2 mm was formed after the RASP process. Nano-sized grains, equiaxed subgrains, and elongated subgrains were observed along the depth of the deformation layer. Dislocation accumulation and dynamic recrystallization were found primarily responsible for the grain refinement process. An obvious microhardness gradient was observed for all of the samples with different RASP processing parameters, and the microhardness in the top surface of 50 m/s-5 min RASP-processed sample is twice that of its coarse-grained (CG) counterpart. The yield strengths of the RASP-processed 5052 Al alloy samples were 1.4–2.6 times that of CG counterparts, while retaining a decent ductility (25–84% that of CG). The superior properties imparted by the gradient structure are expected to expand the application of the 5052 Al alloy as a structural material.

Similar content being viewed by others

References

X.Y. Liu, P.P. Ohotnicky, J.B. Adams, C.L. Rohrer, and R.W. Hyland: Anisotropic surface segregation in Al–Mg alloys. Surf. Sci. 373, 357 (1997).

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45, 103 (2000).

R.Z. Valiev, I.V. Alexandrov, Y.T. Zhu, and T.C. Lowe: Paradox of strength and ductility in metals processed by severe plastic deformation. J. Mater. Res. 17, 5 (2002).

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, and Y.T. Zhu: Fundamentals of superior properties in bulk nanoSPD materials. Mater. Res. Lett. 4, 1 (2016).

N. Tsuji, Y. Saito, H. Utsunomiya, and S. Tanigawa: Ultra-fine grained bulk steel produced by accumulative roll-bonding (ARB) process. Scr. Mater. 40, 795 (1999).

H. Pirgazi, A. Akbarzadeh, R. Petrov, and L. Kestens: Microstructure evolution and mechanical properties of AA1100 aluminum sheet processed by accumulative roll bonding. Mater. Sci. Eng., A 497, 132 (2008).

Y.T. Zhu and T.C. Lowe: Observations and issues on mechanisms of grain refinement during ECAP process. Mater. Sci. Eng., A 291, 46 (2000).

M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon: Review: Processing of metals by equal-channel angular pressing. J. Mater. Sci. 36, 2835 (2001).

M. Kawasaki, Z. Horita, and T.G. Langdon: Microstructural evolution in high purity aluminum processed by ECAP. Acta Mater. 524, 143 (2009).

M. Zha, Y.J. Li, R.H. Mathiesen, R. Bjørge, and H.J. Roven: Microstructure evolution and mechanical behavior of a binary Al–7Mg alloy processed by equal-channel angular pressing. Acta Mater. 84, 42 (2015).

T.L. Tsai, P.L. Sun, P.W. Kao, and C.P. Chang: Microstructure and tensile properties of a commercial 5052 aluminum alloy processed by equal channel angular extrusion. Mater. Sci. Eng., A 342, 144 (2003).

M.P. Liu, H.J. Roven, X.T. Liu, M. Murashkin, R.Z. Valiev, T. Ungar, and L. Balogh: Grain refinement in nanostructured Al–Mg alloys subjected to high pressure torsion. J. Mater. Sci. 45, 4659 (2010).

Y. Cao, Y.B. Wang, R.B. Figueiredo, L. Chang, X.Z. Liao, M. Kawasaki, W.L. Zheng, S.P. Ringer, T.G. Langdon, and Y.T. Zhu: Three-dimensional shear-strain patterns induced by high-pressure torsion and their impact on hardness evolution. Acta Mater. 59, 3903 (2011).

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, and Y.T. Zhu: Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58, 33 (2006).

Y.T. Zhu, X.Z. Liao, and X.L. Wu: Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 57, 1 (2012).

W.W. Jian, G.M. Cheng, W.Z. Xu, H. Yuan, M.H. Tsai, Q.D. Wang, C.C. Koch, Y.T. Zhu, and S.N. Mathaudhu: Ultrastrong Mg alloy via nano-spaced stacking faults. Mater. Res. Lett. 2, 61 (2013).

Loorentz and Y.G. Ko: Effect of differential speed rolling strain on microstructure and mechanical properties of nanostructured 5052 Al alloy. J. Alloys Compd. 586, S205 (2014).

U.G. Gang, S.H. Lee, and W. Jono: The evolution of microstructure and mechanical properties of a 5052 aluminium alloy by the application of cryogenic rolling and warm rolling. Mater. Trans. 50, 82 (2009).

Y.B. Lee, D.H. Shin, and W.J. Nam: Effect of deformation temperature on the formation of ultrafine grains in the 5052 Al alloy. Met. Mater. Int. 10, 407 (2004).

B. Wang, X.H. Chen, F.S. Pan, J.J. Mao, and Y. Fang: Effects of cold rolling and heat treatment on microstructure and mechanical properties of AA 5052 aluminum alloy. Trans. Nonferrous Met. Soc. China 25, 2481 (2015).

K.C. Sekhar, R. Narayanasamy, and K. Velmanirajan: Experimental investigations on microstructure and formability of cryorolled AA 5052 sheets. Mater. Des. 53, 1064 (2014).

J.T. Shi, L.G. Hou, C.Q. Ma, J.R. Zuo, H. Cui, L.Z. Zhuang, and J.S. Zhang: Mechanical properties and microstructures of 5052 Al alloy processed by asymmetric cryorolling. Mater. Sci. Forum 850, 823 (2016).

Y.C. Chen, Y.Y. Huang, C.P. Chang, and P.W. Kao: The effect of extrusion temperature on the development of deformation microstructures in 5052 aluminum alloy processed by equal channel angular extrusion. Acta Mater. 51, 2005 (2003).

Y.T. Zhu and X.Z. Liao: Nanostructured metals: Retaining ductility. Nat. Mater. 3, 351 (2004).

M.A. Meyers, A. Mishra, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427 (2006).

K. Lu: Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 1, 16019 (2016).

T.H. Fang, W.L. Li, N.R. Tao, and K. Lu: Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 331, 1587 (2011).

X.L. Wu, P. Jiang, L. Chen, F.P. Yuan, and Y.T. Zhu: Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. U. S. A. 111, 7197 (2014).

E. Ma and T. Zhu: Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today (2017). Available at: http://dx.doi.org/10.1016/j.mattod.2017.02.003.

X.L. Wu, P. Jiang, L. Chen, and Y.T. Zhu: Synergetic strengthening by gradient structure. Mater. Res. Lett. 2, 185 (2014).

K. Lu and J. Lu: Surface nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach. J. Mater. Sci. Technol. 15, 193 (1999).

K. Lu and J. Lu: Nanostructured surface layer on metallic materials induced by SMAT. Mater. Sci. Eng., A 375–377, 38 (2004).

W.L. Li, N.R. Tao, and K. Lu: Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scr. Mater. 59, 546 (2008).

X.C. Liu, H.W. Zhang, and K. Lu: Strain-induced ultrahard and ultrastable nanolaminated structure in nickel. Science 342, 337 (2014).

X. Wang, Y.S. Li, Q. Zhang, Y.H. Zhao, and Y.T. Zhu: Gradient structured copper by rotationally accelerated shot peening. J. Mater. Sci. Technol. 33, 758 (2017).

Z. Horita, D.J. Smith, M. Nemoto, R.Z. Valiev, and T.G. Langdon: Observations of grain boundary structure in submicrometer-grained Cu and Ni using high-resolution electron microscopy. J. Mater. Res. 13, 446 (1998).

K. Oh-ishi, Z. Horita, D.J. Smith, and T.G. Langdon: Grain boundary structure in Al–Mg and Al–Mg–Sc alloys after equal-channel angular pressing. J. Mater. Res. 16, 583 (2001).

Y. Cao, Y.B. Wang, X.H. An, X.Z. Liao, M. Kawasaki, S.P. Ringer, T.G. Langdon, and Y.T. Zhu: Concurrent microstructural evolution of ferrite and austenite in a duplex stainless steel processed by high-pressure torsion. Acta Mater. 63, 16 (2014).

K.T. Park and D.H. Shin: Microstructural interpretation of negligible strain-hardening behavior of submicrometer-grained low-carbon steel during tensile deformation. Metall. Mater. Trans. A 33, 705 (2002).

Y.T. Zhu, J.Y. Huang, J. Gubicza, T. Ungar, Y.M. Wang, E. Ma, and R.Z. Valiev: Nanostructures in Ti processed by severe plastic deformation. J. Mater. Res. 18, 1908 (2003).

H.R. Song, Y.S. Kim, and W.J. Nam: Mechanical properties of ultrafine grained 5052 Al alloy produced by accumulative roll-bonding and cryogenic rolling. Met. Mater. Int. 12, 7 (2006).

A. Mishra, B.K. Kad, F. Gregori, and M.A. Meyers: Microstructural evolution in copper subjected to severe plastic deformation: Experiments and analysis. Acta Mater. 55, 13 (2007).

Y.S. Li, N.R. Tao, and K. Lu: Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 56, 230 (2008).

H.Q. Sun, Y.N. Shi, M.X. Zhang, and K. Lu: Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy. Acta Mater. 55, 975 (2007).

H.W. Chang, P.M. Kelly, Y.N. Shi, and M.X. Zhang: Effect of eutectic Si on surface nanocrystallization of Al–Si alloys by surface mechanical attrition treatment. Mater. Sci. Eng., A 530, 304 (2011).

M.X. Yang, Y. Pan, F.P. Yuan, Y.T. Zhu, and X.L. Wu: Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 4, 145 (2016).

ACKNOWLEDGMENTS

Financial supports from the National Key R&D Program of China (Grant No. 2017YFA0204403), National Natural Science Foundation of China (Grant Nos. 51301092, 51501092, and 51601094), Nanjing University of Science and Technology (Grant No. AE89991), Pangu Foundation, and the Jiangsu Key Laboratory of Advanced Micro&Nano Materials and Technology are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

A previous error in this article has been corrected. For details, see 10.1557/jmr.2017.459

Rights and permissions

About this article

Cite this article

Li, Y., Li, L., Nie, J. et al. Microstructural evolution and mechanical properties of a 5052 Al alloy with gradient structures. Journal of Materials Research 32, 4443–4451 (2017). https://doi.org/10.1557/jmr.2017.310

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.310