Abstract

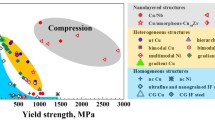

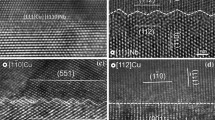

Nanoscale metallic material composites consisting of bilayer and trilayer systems of two and three different metallic alternating layers show significant gains in hardness over monolithic single phase films. One of the main applications of these composites can be as protective coatings to technical components to increase their lifespan acting as a mechanical barrier to the carriers of permanent deformation. In this work, we study the strength of bilayer structures made of alternating layers of niobium (Nb) and copper–nickel (Cu–Ni) alloys. The effect of the layer size and composition on strength and hardening as well as the effect of the metal–alloy interface on the dislocation motion is investigated. The simulations reveal a close relationship between the atomic composition of the alloy and the hardening of the film. The results are also compared with experimental findings on nanopillars made of similar structures, and strong similarities are revealed and discussed.

Similar content being viewed by others

References

A. Misra and H. Kung: Deformation behavior of nanostructured metallic multilayers. Adv. Eng. Mater. 3 (4), 217 (2001).

R. Hoagland, T. Mitchell, J. Hirth, and H. Kung: On the strengthening effects of interfaces in multilayer fcc metallic composites. Philos. Mag. A 82 (4), 643 (2002).

A. Bellou, C.T. Overman, H.M. Zbib, D.F. Bahr, and A. Misra: Strength and strain hardening behavior of Cu-based bilayers and trilayers. Scr. Mater. 64 (7), 641 (2011).

Y. Wang, A. Misra, and R. Hoagland: Fatigue properties of nanoscale Cu/Nb multilayers. Scr. Mater. 54 (9), 1593 (2006).

A. Misra, M. Demkowicz, X. Zhang, and R. Hoagland: The radiation damage tolerance of ultra-high strength nanolayered composites. JOM 59 (9), 62 (2007).

J. McKeown, A. Misra, H. Kung, R.G. Hoagland, and M. Nastasi: Microstructures and strength of nanoscale Cu–Ag multilayers. Scr. Mater. 46 (8), 593 (2002).

D.R. Economy, B.M. Schultz, and M.S. Kennedy: Impacts of accelerated aging on the mechanical properties of Cu–Nb nanolaminates. J. Mater. Sci. 47 (19), 6986 (2012).

A. Misra, M. Verdier, Y.C. Lu, H. Kung, T.E. Mitchell, M. Nastasi, and D.J. Embury: Structure and mechanical properties of Cu–X (X = Nb, Cr, Ni) nanolayered composites. Scr. Mater. 39 (4/5), 555 (1998).

N. Abdolrahim, H.M. Zbib, and D.F. Bahr: Multiscale modeling and simulation of deformation in nanoscale metallic multilayer systems. Int. J. Plast. 52, 33 (2014).

I.N. Mastorakos and N. Abdolrahim: Deformation mechanisms in composite nano-layered metallic and nanowire structures. Int. J. Mech. Sci. 52, 295 (2010).

J.D. Gale, A. Achuthan, and D.J. Morrison: Indentation size effect (ISE) in copper subjected to severe plastic deformation (SPD). Metall. Mater. Trans. A 45 (5), 2487 (2014).

I.N. Mastorakos, H.M. Zbib, and D.F. Bahr: Deformation mechanisms and strength in nanoscale multilayer metallic composites with coherent and incoherent interfaces. Appl. Phys. Lett. 94 (17), 173114 (2009).

S. Shao, H.M. Zbib, I.N. Mastorakos, and D.F. Bahr: The void nucleation strengths of the Cu–Ni–Nb-based nanoscale metallic multilayers under high strain rate tensile loadings. Comput. Mater. Sci. 82, 435 (2014).

D. Mitlin, A. Misra, V. Radmilovic, M. Nastasi, R. Hoagland, D. Embury, J. Hirth, and T. Mitchell: Formation of misfit dislocations in nanoscale Ni–Cu bilayer films. Philos. Mag. 84 (7), 719 (2004).

D. Mitlin, A. Misra, T. Mitchell, J. Hirth, and R. Hoagland: Interface dislocation structures at the onset of coherency loss in nanoscale Ni–Cu bilayer films. Philos. Mag. 85 (28), 3379 (2005).

A. Misra, J.P. Hirth, and R.G. Hoagland: Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 53 (18), 4817 (2005).

F. Akasheh, H. Zbib, J. Hirth, R. Hoagland, and A. Misra: Dislocation dynamics analysis of dislocation intersections in nanoscale metallic multilayered composites. J. Appl. Phys. 101 (8), 84314 (2007).

A. Misra, M. Demkowicz, J. Wang, and R. Hoagland: The multiscale modeling of plastic deformation in metallic nanolayered composites. JOM 60 (4), 39 (2008).

I.N. Mastorakos, A. Bellou, D.F. Bahr, and H.M. Zbib: Size-dependent strength in nanolaminate metallic systems. J. Mater. Res. 26 (10), 1179 (2011).

H.C. Barshilia and K.S. Rajam: Characterization of Cu/Ni multilayer coatings by nanoindentation and atomic force microscopy. Surf. Coat. Technol. 155 (2–3), 195 (2002).

J. Wang and A. Misra: An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr. Opin. Solid State Mater. Sci. 15 (1), 20 (2011).

J.Y. Zhang, X. Zhang, G. Liu, G.J. Zhang, and J. Sun: Scaling of the ductility with yield strength in nanostructured Cu/Cr multilayer films. Scr. Mater. 63 (1), 101 (2010).

H.M. Zbib, C.T. Overman, F. Akasheh, and D. Bahr: Analysis of plastic deformation in nanoscale metallic multilayers with coherent and incoherent interfaces. Int. J. Plast. 27 (10), 1618 (2011).

S. Shao, H.M. Zbib, I.N. Mastorakos, and D.F. Bahr: Deformation mechanisms, size effects, and strain hardening in nanoscale metallic multilayers under nanoindentation. J. Appl. Phys. 112 (4), 44307 (2012).

N.J. Petch: The cleavage strength of polycrystals. J. Iron Steel Inst., London 174, 25 (1953).

R.L. Schoeppner, J.M. Wheeler, J. Zechner, J. Michler, H.M. Zbib, and D.F. Bahr: Coherent interfaces increase strain-hardening behavior in tri-component nano-scale metallic multilayer thin films. Mater. Res. Lett. 3 (2), 114 (2015).

M. Verdier, H. Huang, F. Spaepen, J.D. Embury, and H. Kung: Microstructure, indentation and work hardening of Cu/Ag multilayers. Philos. Mag. 86 (32), 5009 (2006).

H. Huang and F. Spaepen: Tensile testing of free-standing Cu, Ag and Al thin films and Ag/Cu multilayers. Acta Mater. 48 (12), 3261 (2000).

J. Wang, Q. Zhou, S. Shao, and A. Misra: Strength and plasticity of nanolaminated materials. Mater. Res. Lett. 5 (1), 1 (2017).

N. Mara, D. Bhattacharyya, P. Dickerson, R. Hoagland, and A. Misra: Deformability of ultrahigh strength 5 nm Cu/Nb nanolayered composites. Appl. Phys. Lett. 92 (23), 231901 (2008).

R. Rabe, J-M. Breguet, P. Schwaller, S. Stauss, F-J. Haug, J. Patscheider, and J. Michler: Observation of fracture and plastic deformation during indentation and scratching inside the scanning electron microscope. Thin Solid Films 469–470, 206 (2004).

J.M. Wheeler and J. Michler: Elevated temperature, nano-mechanical testing in situ in the scanning electron microscope. Rev. Sci. Instrum. 84 (4), 45103 (2013).

S.J. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comp. Physiol. 117, 1 (1995).

M. Daw and M. Baskes: Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1983).

A.F. Voter: Intermetallic Compounds. Principles and Practice (Wiley, Chichester, 1995).

R.G. Hoagland, J.P. Hirth, and A. Misra: On the role of weak interfaces in blocking slip in nanoscale layered composites. Philos. Mag. 86 (23), 3537 (2006).

Q. Zhang, W.S. Lai, and B.X. Liu: Atomic structure and physical properties of Ni–Nb amorphous alloys determined by an n-body potential. J. Non-Cryst. Solids 261 (1–3), 137 (2000).

S. Melchionna, G. Ciccotti, and B. Lee Holian: Hoover NPT dynamics for systems varying in shape and size. Mol. Phys. 78 (3), 533 (1993).

R. Hoagland, R. Kurtz, and C. Henager: Slip resistance of interfaces and the strength of metallic multilayer composites. Scr. Mater. 50 (6), 775 (2004).

I.N. Sneddon: The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

R.W. Hertzberg, R.P. Vinci, and J.L. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, 5th ed. (John Wiley & Sons, Inc, Hoboken, NJ, 2012).

A. Stukowski, V.V. Bulatov, and A. Arsenlis: Automated identification and indexing of dislocations in crystal interfaces. Modell. Simul. Mater. Sci. Eng. 20 (8), 85007 (2012).

ACKNOWLEDGMENTS

This work was supported in part by the National Science Foundation under Grant No. CMMI 1634772/1634640 and in part by the US Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences under Grant No. DE-FG02-07ER46435. The authors acknowledge access, through an approved user project, to the Center for Integrated Nanotechnologies (CINT), a DOE Office of Basic Energy Sciences user facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mastorakos, I.N., Schoeppner, R.L., Kowalczyk, B. et al. The effect of size and composition on the strength and hardening of Cu–Ni/Nb nanoscale metallic composites. Journal of Materials Research 32, 2542–2550 (2017). https://doi.org/10.1557/jmr.2017.213

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.213