Abstract

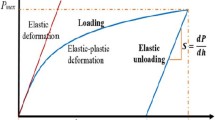

The unloading part of a load–displacement curve from instrumented indentation tests is usually approximated by a power law (Oliver and Pharr model), where the load is the dependent variable. This approach generally fits well the data. Nevertheless, the convergence is occasionally quite questionable. In this regard, we propose a different approach for the Oliver and Pharr model, called the inverted approach, since it assigns the displacement as the dependent variable. Both models were used to fit the unloading curves from nanoindentation tests on fused silica and aluminum, applying a general least squares procedure. Generally, the inverted methodology leads to similar results for the fitting parameters and the elastic modulus (E) when convergence is achieved. Nevertheless, this approach facilitates the convergence, because it is a better conditioned problem. Additionally, by Monte Carlo simulations we found that robustness is improved using the inverted approach, since the estimation of E is more accurate, especially for aluminum.

Similar content being viewed by others

References

M.R. VanLandingham: Review of instrumented indentation. J. Res. Natl. Inst. Stand. Technol. 108, 249 (2003).

J. Hay: Introduction to instrumented indentation testing. Exp. Tech. 33, 66 (2009).

M. Dao, N. Chollacoop, K.J. Van Vliet, T.A. Venkatesh, and S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

J.M. Antunes, J.V. Fernandes, L.F. Menezes, and B.M. Chaparro: A new approach for reverse analyses in depth-sensing indentation using numerical simulation. Acta Mater. 55, 69 (2007).

M. Mata, M. Anglada, and J. Alcalá: Contact deformation regimes around sharp indentations and the concept of the characteristic strain. J. Mater. Res. 17, 964 (2002).

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 64, 533 (1981).

J.S. Field, M.V. Swain, and R.D. Dukino: Determination of fracture toughness from the extra penetration produced by indentation-induced pop-in. J. Mater. Res. 18, 1412 (2003).

Y.P. Cao and J. Lu: A new method to extract the plastic properties of metal materials from an instrumented spherical indentation loading curve. Acta Mater. 52, 4023 (2004).

M.T. Attaf: Connection between the loading curve models in elastoplastic indentation. Mater. Lett. 58, 3491 (2004).

K.K. Jha, N. Suksawang, and A. Agarwal: Analytical method for the determination of indenter constants used in the analysis of nanoindentation loading curves. Scr. Mater. 63, 281 (2010).

D. Chicot and D. Mercier: Improvement in depth-sensing indentation to calculate the universal hardness on the entire loading curve. Mech. Mater. 40, 171 (2008).

D. Chicot, L. Gil, K. Silva, F. Roudet, E.S. Puchi-Cabrera, M.H. Staia, and D.G. Teer: Thin film hardness determination using indentation loading curve modelling. Thin Solid Films 518, 5565 (2010).

K. Zeng and C-h. Chiu: An analysis of load–penetration curves from instrumented indentation. Acta Mater. 49, 3539 (2001).

J. Gong, H. Miao, and Z. Peng: A new function for the description of the nanoindentation unloading data. Scr. Mater. 49, 93 (2003).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

M.F. Doerner and W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1, 601 (1986).

J. Gubicza, A. Juhász, P. Tasnádi, P. Arató, and G. Vörös: Determination of the hardness and elastic modulus from continuous Vickers indentation testing. J. Mater. Sci. 31, 3109 (1996).

M. Yetna N’Jock, F. Roudet, M. Idriss, O. Bartier, and D. Chicot: Work-of-indentation coupled to contact stiffness for calculating elastic modulus by instrumented indentation. Mech. Mater. 94, 170 (2016).

K.K. Jha, N. Suksawang, and A. Agarwal: A new insight into the work-of-indentation approach used in the evaluation of material’s hardness from nanoindentation measurement with Berkovich indenter. Comput. Mater. Sci. 85, 32 (2014).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

G.M. Pharr and A. Bolshakov: Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660 (2002).

J.L. Loubet, M. Bauer, A. Tonck, S. Bec, and B. Gauthier-Manuel: Nanoindentation with a Surface Force Apparatus, M. Nastasi et al., eds. (Springer, Dordrecht, 1993); p. 429.

G. Hochstetter, A. Jimenez, and J.L. Loubet: Strain-rate effects on hardness of glassy polymers in the nanoscale range. Comparison between quasi-static and continuous stiffness measurements. J. Macromol. Sci., Part B: Phys. 38, 681 (1999).

P.R. Bevington and D.K. Robinson: Data Reduction and Error Analysis for the Physical Sciences (McGraw-Hill, New York, 2003).

L.C. Brown and P. Mac Berthouex: Statistics for Environmental Engineers (CRC Press, Boca Raton, 2002).

K. Smyth: Nonlinear Regression in Encyclopedia of Environmetrics, A.H. El-Shaarawi and W.W. Piegorsch, eds. (Wiley, New York, 2002).

4.1.4.2. Nonlinear Least Squares Regression. [Online]. Available at: http://www.itl.nist.gov/div898/handbook/pmd/section1/pmd142.htm (accessed: 13-Aug-2016).

K. Madsen, H.B. Nielsen, and O. Tingleff: Methods for non-linear least squares problems. In Informatics and Mathematical Modeling (Technical University of Denmark, Kongens Lyngby, 2004).

S. Gratton, A.S. Lawless, and N.K. Nichols: Approximate Gauss-Newton methods for nonlinear least squares problems. SIAM J. Optim. 18, 106 (2007).

D.J. Whitehouse: Handbook of Surface and Nanometrology, 2nd ed. (CRC Press, Boca Raton, 2010).

A.C. Fischer-Cripps: Critical review of analysis and interpretation of nanoindentation test data. Surf. Coat. Technol. 200, 4153 (2006).

J. Menčík and M.V. Swain: Errors associated with depth-sensing microindentation tests. J. Mater. Res. 10, 1491 (1995).

A. Fischer-Cripps: A review of analysis methods for sub-micron indentation testing. Vacuum 58, 569 (2000).

C.A. Peters: Statistics for analysis of experimental data. In Environ. Eng. Process. Lab. Man. (S. E. Powers, Champaign, 2001); p. 1–25.

L.N. Trefethen and D. Bau, III: Numerical Linear Algebra (SIAM, Philadelphia, 1997).

J. Erhel, N. Nassif, and P. Bernard: Calcul matriciel et systèmes linéaires (INSA Rennes, Rennes, 2012).

M. Sofroniou and G. Spaletta: Precise numerical computation. J. Log. Algebr. Program. 64, 113 (2005).

“JCGM 101:2008-Supplement 1 to the ‘Guide to the Expression of Uncertainty in Measurement’-Propagation of distributions using a Monte Carlo method.” [Online]. Available: http://www.bipm.org/en/publications/guides/gum.html (accessed: 27-Feb-2017).

“ISO 14577-1:2015-Metallic materials—Instrumented indentation test for hardness and materials parameters—Part 1: Test method,” ISO. [Online]. Available: http://www.iso.org/iso/home/store/catalogue_ics/catalogue_detail_ics.htm?csnumber=56626 (accessed: 04-Sep-2016).

A. Iost, G. Guillemot, Y. Rudermann, and M. Bigerelle: A comparison of models for predicting the true hardness of thin films. Thin Solid Films 524, 229 (2012).

J. Isselin, A. Iost, J. Golek, D. Najjar, and M. Bigerelle: Assessment of the constitutive law by inverse methodology: Small punch test and hardness. J. Nucl. Mater. 352, 97 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kossman, S., Coorevits, T., Iost, A. et al. A new approach of the Oliver and Pharr model to fit the unloading curve from instrumented indentation testing. Journal of Materials Research 32, 2230–2240 (2017). https://doi.org/10.1557/jmr.2017.120

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.120