Abstract

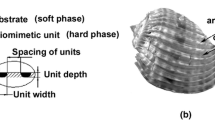

Wear resistance plays an important role to ensure the machining precision of machine tool using gray cast iron guide rail. Bio-inspired surfaces imitating the cuticle of desert scorpion and shell archetype with alternate units were prepared on gray cast iron using biomimetic coupling laser remelting in air and water. Samples consisting of striature bionic units with various distributions were examined under dry sliding condition using a home-made wear testing machine. It was found that samples with bionic units displayed better wear resistance than the untreated gray cast iron. While samples with bionic units processed in water by laser returned highest wear resistance in the short run, samples with alternatively distributed units (processed by laser) presented better wear resistance in the long run. However, to understand the stress distributions and the wear mechanism of the samples finite element method was used in this study. Based on the experimental evidences, a two-stage wear mechanism was proposed.

Similar content being viewed by others

References

J.M. Walter: Machine tool guideway. U.S. Patent 2,378,343, June 12, 1945.

M. Nakano, K. Miyake, A. Korenaga, S. Sasaki, and Y. Ando: Tribological properties of patterned NiFe-covered Si surfaces. Tribol. Lett. 35, 133 (2009).

X.B. Liu, G. Yu, J. Guo, Q.Y. Shang, Z.G. Zhang, and Y.J. Gu: Analysis of laser surface hardened layers of automobile engine cylinder liner. J. Iron Steel Res. Int. 14, 42 (2007).

Y.G. Schneider: Formation of surfaces with uniform micropatterns on precision machine and instruments parts. Precis. Eng. 6, 219 (1984).

A.N. Panckow, J. Steffenhagen, B. Wegener, L. Dübner, and F. Lierath: Application of a novel vacuum-arc ion-plating technology for the design of advanced wear resistant coatings. Surf. Coat. Technol. 138, 71 (2001).

F.C. Campbell: Elements of Metallurgy and Engineering Alloys (ASM International, USA, 2008).

J.M. Walter: Machine tool guide: U.S. Patent 2,522,695, September 19, 1950.

A. Neville, A. Morina, T. Haque, and M. Voong: Compatibility between tribological surfaces and lubricant additives-how friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 40, 1680 (2007).

Y. Zang, Y. Chen, R. He, and B. Shen: Investigation of tribological properties of brake shoe materials—Phosphorous cast irons with different graphite morphologies. Wear 166, 179 (1993).

J. Qu, P.J. Blau, S. Dai, H. Luo, and H.M. Meyer, II: Ionic liquids as novel lubricants and additives for diesel engine applications. Tribol. Lett. 35(3), 181 (2009).

K.Y. Benyounis, O.M.A. Fakron, J.H. Abboud, A.G. Olabi, and M.J.S. Hashmi: Surface melting of nodular cast iron by Nd-YAG laser and TIG. J. Mater. Process. Technol. 170, 127 (2005).

N. Sun, H. Shan, H. Zhou, D. Chen, X. Li, W. Xia, and L. Ren: Friction and wear behaviors of compacted graphite iron with different biomimetic units fabricated by laser cladding. Appl. Surf. Sci. 258, 7699 (2012).

H. Zhou, N. Sun, H. Shan, D. Ma, X. Tong, and L.Q. Ren: Bio-inspired wearable characteristic surface: Wear behavior of cast iron with biomimetic units processed by laser. Appl. Surf. Sci. 253, 9513 (2007).

Z.K. Chen, S.C. Lu, X.B. Song, H. Zhang, W.S. Yang, and H. Zhou: Effects of bionic units on the fatigue wear of gray cast iron surface with different shapes and distributions. Opt. Laser Technol. 66, 166 (2015).

X.C. Zhang, B.S. Xu, F.Z. Xuan, Z.D. Wang, and S.T. Tu: Failure mode and fatigue mechanism of laser remelted plasma sprayed Ni alloy coatings in rolling contact. Surf. Coat. Technol. 205, 3119 (2011).

S. Kamat, X. Su, and R. Ballarini: Structural basis for the fracture toughness of the shell of conch strombus gigas. Nature 205, 1036 (2000).

A.W. Pederson, J.W. Ruberti, and P.B. Messersmith: Thermal assembly of a biomimetic mineral/collagen composite. Biomaterials 24, 4881 (2003).

Y. Hu, Z.W. Han, M.X. Xu, and Z.H. Zhang: Anti-wear properties on 20CrMnTi steel surfaces with biomimetic non-smooth units. Sci. China: Technol. Sci. 53, 2920 (2010).

Z. Wang, Z. Zhang, Y. Sun, K. Gao, Y.H. Liang, and X.J. Li: Wear behavior of bionic impregnated diamond bits. Tribol. Int. 94, 217 (2016).

L.Q. Ren: Progress in the study on anti-adhesion and resistance reduction of terrain machines. Sci. China, Ser. E: Technol. Sci. 52, 273 (2009).

J.H. Wu, B.S. Phillips, W.P. Jiang, J.H. Sanders, J.S. Zabinski, and A.P. Malshe: Bio-inspired surface engineering and tribology of MoS2 over coated CBN–TiN composite coating. Wear 261, 592 (2006).

A.K. Dubey and V. Yadava: Laser beam machining–A review. Int. J. Mach. Tool. Manu. 48, 609 (2008).

A. Blarasin, S. Corcoruto, A. Belmondo, and D. Bacci: Development of a laser surface melting process for improving of the wear resistance of gray cast iron. Wear 86, 315 (1983).

P. Schaaf, V. Biehl, U. Gonser, M. Bamberger, and P. Bauer: Laser remelting of cast iron: A Mössbauer study. J. Mater. Sci. 26, 5019 (1991).

Q.C. Guo, H. Zhou, C.T. Wang, W. Zhang, P.Y. Lin, N. Sun, and L. Ren: Effect of medium on friction and wear properties of compacted graphite cast iron processed by biomimetic coupling laser remelting process. Appl. Surf. Sci. 255, 6266 (2009).

H. Zhou, C. Wang, Q. Guo, J. Yu, M. Wang, X. Liao, Y. Zhao, and L. Ren: Influence of processing medium on frictional wear properties of ball bearing steel prepared by laser surface melting coupled with bionic principles. J. Alloys Compd. 505, 801 (2010).

Y. Liu, H. Zhou, H. Su, C. Yang, J. Cheng, P. Zhang, and L. Ren: Effect of electrical pulse treatment on the thermal fatigue resistance of bionic compacted graphite cast iron processed in water. Mater. Des. 39, 344 (2012).

X. Tong, H. Zhou, M. Liu, and M.J. Dai: Effects of striated laser tracks on thermal fatigue resistance of cast iron samples with biomimetic non-smooth surface. Mater. Des. 32(2), 796 (2011).

Z.K. Chen, T. Zhou, R.Y. Zhao, H.F. Zhang, S.C. Lu, W.S. Yang, and H. Zhou: Improved fatigue wear resistance of gray cast iron by localized laser carburizing. Mater. Sci. Eng., A 644, 1 (2015).

D. Cong, H. Zhou, Z. Ren, Z. Zhang, H. Zhang, C. Meng, and C. Wang: The thermal fatigue resistance of H13 steel repaired by a biomimetic laser remelting process. Mater. Des. 55, 597 (2014).

C. Meng, H. Zhou, H. Zhang, X. Tong, D. Cong, C. Wang, and L. Ren: The comparative study of thermal fatigue behavior of H13 die steel with biomimetic non-smooth surface processed by laser surface melting and laser cladding. Mater. Des. 51, 886 (2013).

Z.B. Pang, H. Zhou, G. Xie, D. Cong, C. Meng, and L.Q. Ren: Effect of bionic coupling units’ forms on wear resistance of gray cast iron under dry linear reciprocating sliding condition. Opt. Laser Technol. 70, 89 (2015).

L. Pawlowski: The Science and Engineering of Thermal Spray Coatings (John Wiley & Sons, England, 1995).

R.I. Carroll and J.H. Beynon: Decarburisation and rolling contact fatigue of a rail steel. Wear 260, 523 (2006).

N. Pugno, M. Ciavarella, P. Cornetti, and A. Carpinteri: A generalized Paris’ law for fatigue crack growth. J. Mech. Phys. Solids 54, 1333 (2006).

J. Jiang, F.H. Stott, and M.M. Stack: A generic model for dry sliding wear of metals at elevated temperatures. Wear 256, 973 (2004).

ACKNOWLEDGMENT

This article was supported by Project 985–High Performance Materials of Jilin University and the Project 985–Bionic Engineering Science and Technology In novation and National Natural Science Foundation of China (No. 51275200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sui, Q., Zhou, H., Zhang, H. et al. Effect of alternate biomimetic coupling units on dry sliding wear resistance of gray cast iron. Journal of Materials Research 32, 343–353 (2017). https://doi.org/10.1557/jmr.2016.474

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.474