Abstract

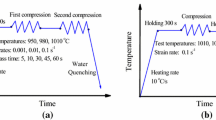

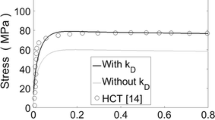

The classical dynamic recrystallization (DRX) kinetics models, such as Avrami equation, are often used to describe the DRX behaviors of alloys. However, it is found that the classical DRX kinetics models cannot be directly applied to evaluate DRX volume fractions under inconstant deformation conditions, such as at fluctuant deformation temperature and strain rate. It obviously limits their application in the practical industrial production. Therefore, an improved DRX kinetics model is proposed based on the hypothesis that the derivatives of DRX volume fraction with respect to strain only depends on the current deformation temperature, strain rate, and DRX volume fraction. To verify the improved DRX kinetics model, the hot compressive tests in which the strain rate is inconstant are carried out on a solution-treated Ni-based superalloy. Experimental results indicate that the improved DRX kinetics model can well predict the DRX behavior under inconstant deformation conditions.

Similar content being viewed by others

References

H.J. McQueen: Development of dynamic recrystallization theory. Mater. Sci. Eng., A 387–389, 203 (2004).

J. De Jaeger, D. Solas, O. Fandeur, J. Schmitt, and C. Rey: 3D numerical modeling of dynamic recrystallization under hot working: Application to Inconel 718. Mater. Sci. Eng., A 33, 646 (2015).

H. Beladi and P.D. Hodgson: Effect of carbon content on the recrystallization kinetics of Nb-steels. Scr. Mater. 56, 1059 (2007).

S. Vervynckt, K. Verbeken, P. Thibaux, and Y. Houbaert: Recrystallization–precipitation interaction during austenite hot deformation of a Nb microalloyed steel. Mater. Sci. Eng., A 528, 5519 (2011).

G.L. Ji, F.G. Li, Q.H. Li, H.Q. Li, and Z. Li: Research on the dynamic recrystallization kinetics of Aermet100 steel. Mater. Sci. Eng., A 527, 2350 (2010).

S.D. Gu, L.W. Zhang, C. Zhang, J.H. Ruan, and Y. Zhen: Modeling the effects of processing parameters on dynamic recrystallization behavior of deformed 38MnVS6 steel. J. Mater. Eng. Perform. 24, 1790 (2015).

M.S. Chen, Y.C. Lin, and X.S. Ma: The kinetics of dynamic recrystallization of 42CrMo steel. Mater. Sci. Eng., A 556, 260 (2012).

B.C. Zhao, T. Zhao, G.Y. Li, and Q. Lu: The kinetics of dynamic recrystallization of a low carbon vanadium-nitride microalloyed steel. Mater. Sci. Eng., A 604, 117 (2014).

D. Xu, M.Y. Zhu, Z.Y. Tang, and C. Sun: Determination of the dynamic recrystallization kinetics model for SCM435 steel. J. Wuhan. Univ. Technol., Mater. Sci. Ed. 28, 819 (2013).

Y.G. Liu, M.Q. Li, and J. Luo: The modelling of dynamic recrystallization in the isothermal compression of 300M steel. Mater. Sci. Eng., A 574, 1 (2013).

H. Mirzadeh and A. Najafizadeh: Prediction of the critical conditions for initiation of dynamic recrystallization. Mater. Des. 31, 1174 (2010).

Y.W. Xu, D. Tang, Y. Song, and X.G. Pan: Dynamic recrystallization kinetics model of X70 pipeline steel. Mater. Des. 39, 168 (2012).

S. Mandal, P.V. Sivaprasad, and R.K. Dube: Modeling microstructural evolution during dynamic recrystallization of Alloy D9 using artificial neural network. J. Mater. Eng. Perform. 16, 672 (2007).

A. Momeni and K. Dehghani: Prediction of dynamic recrystallization kinetics and grain size for 410 martensitic stainless steel during hot deformation. Met. Mater. Int. 16, 843 (2010).

G.R. Ebrahimi, H. Keshmiri, A. Momeni, and M. Mazinani: Dynamic recrystallization behavior of a superaustenitic stainless steel containing 16%Cr and 25%Ni. Mater. Sci. Eng., A 528, 7488 (2011).

G.R. Stewart, J.J. Jonas, and F. Montheillet: Kinetics and critical conditions for the initiation of dynamic recrystallization in 304 stainless steel. ISIJ Int. 44, 1581 (2004).

A. Marchattiwar, A. Sarkar, J.K. Chakravartty, and B.P. Kashyap: Dynamic recrystallization during hot deformation of 304 austenitic stainless steel. J. Mater. Eng. Perform. 22, 2168 (2013).

D. Ohadi, M.H. Parsa, and H. Mirzadeh: Development of dynamic recrystallization maps based on the initial grain size. Mater. Sci. Eng., A 565, 90 (2013).

G.R. Ebrahimi, H. Keshmiri, A.R. Maldad, and A. Momeni: Dynamic recrystallization behavior of 13%Cr martensitic stainless steel under hot working condition. J. Mater. Sci. Technol. 28, 467 (2012).

M. El Wahabi, L. Gavard, F. Montheillet, J.M. Cabrera, and J.M. Prado: Effect of initial grain size on dynamic recrystallization in high purity austenitic stainless steels. Acta Mater. 53, 4605 (2005).

G.L. Ji, Q. Li, and L. Li: The kinetics of dynamic recrystallization of Cu–0.4Mg alloy. Mater. Sci. Eng., A 586, 197 (2013).

P. Changizian, A. Zarei-Hanzaki, and H.R. Abedi: On the recrystallization behavior of homogenized AZ81 magnesium alloy: The effect of mechanical twins and γ precipitates. Mater. Sci. Eng., A 558, 44 (2012).

D.X. Zhang, X.Y. Yang, H. Sun, Y. Li, J. Wang, Z.R. Zhang, Y.X. Ye, and T. Sakai: Dynamic recrystallization behaviors and the resultant mechanical properties of a Mg–Y–Nd–Zr alloy during hot compression after aging. Mater. Sci. Eng., A 640, 51 (2015).

T.C. Xu, X.D. Peng, J. Qin, Y.F. Chen, Y. Yang, and G.B. Wei: Dynamic recrystallization behavior of Mg–Li–Al–Nd duplex alloy during hot compression. J. Alloys Compd. 639, 79 (2015).

H.C. Xiao, S.N. Jiang, B. Tang, W.H. Hao, Y.H. Gao, Z.Y. Chen, and C.M. Liu: Hot deformation and dynamic recrystallization behaviors of Mg–Gd–Y–Zr alloy. Mater. Sci. Eng., A 628, 311 (2015).

B.J. Lv, J. Peng, D.W. Shi, A.T. Tang, and F.S. Pan: Constitutive modeling of dynamic recrystallization kinetics and processing maps of Mg–2.0Zn–0.3Zr alloy based on true stress–strain curves. Mater. Sci. Eng., A 560, 727 (2013).

N. Cui, F.T. Kong, X.P. Wang, Y.Y. Chen, and H.T. Zhou: Hot deformation behavior and dynamic recrystallization of a β-solidifying TiAl alloy. Mater. Sci. Eng., A 652, 231 (2016).

K. Tan, J. Li, Z.J. Guan, J.B. Yang, and J.X. Shu: The identification of dynamic recrystallization and constitutive modeling during hot deformation of Ti55511 titanium alloy. Mater. Des. 84, 204 (2015).

Y.Q. Ning, Z.K. Yao, M.W. Fu, and H.Z. Guo: Recrystallization of the hot isostatic pressed nickel-base superalloy FGH4096: I. Microstructure and mechanism. Mater. Sci. Eng., A 528, 8065 (2011).

H.B. Zhang, K.F. Zhang, H.P. Zhou, Z. Lu, C.H. Zhao, and X.L. Yang: Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation. Mater. Des. 80, 51 (2015).

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, and M. He: Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 57, 568 (2014).

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, and L.T. Li: EBSD study of a hot deformed nickel-based superalloy. J. Alloys Compd. 640, 101 (2015).

Y.C. Lin, D.G. He, M.S. Chen, X.M. Chen, C.Y. Zhao, X. Ma, and Z.L. Long: EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel-based superalloy during hot compressive deformation. Mater. Des. 97, 13 (2016).

M.S. Chen, Y.C. Lin, K.K. Li, and Y. Zhou: A new method to establish dynamic recrystallization kinetics model of a typical solution-treated Ni-based superalloy. Comput. Mater. Sci. 122, 150 (2016).

H. Riedel and J. Svoboda: A model for strain hardening, recovery, recrystallization and grain growth with applications to forming processes of nickel base alloys. Mater. Sci. Eng., A 665, 175 (2016).

H.Y. Wu, L.X. Du, and X.H. Liu: Dynamic recrystallization and precipitation behavior of Mn–Cu–V weathering steel. J. Mater. Sci. Technol. 27, 1131 (2011).

H. Hallberg, B. Svendsen, T. Kayser, and M. Ristinmaa: Microstructure evolution during dynamic discontinuous recrystallization in particle-containing Cu. Comput. Mater. Sci. 84, 327 (2014).

I. Mejía, A. Bedolla-Jacuinde, C. Maldonado, and J.M. Cabrera: Determination of the critical conditions for the initiation of dynamic recrystallization in boron microalloyed steels. Mater. Sci. Eng., A 528, 4133 (2011).

G.Z. Quan, S.A. Pu, H.R. Wen, Z.Y. Zou, and J. Zhou: Quantitative analysis of dynamic softening behaviors induced by dynamic recrystallization for Ti–10V–2Fe–2Al alloy. High Temp. Mater. Process. 34, 549 (2015).

J.J. Jonas, X. Quelennec, L. Jiang, and É. Martin: The Avrami kinetics of dynamic recrystallization. Acta Mater. 57, 2748 (2009).

J. Liu, Z. Cui, and L. Ruan: A new kinetics model of dynamic recrystallization for magnesium alloy AZ31B. Mater. Sci. Eng., A 529, 300 (2011).

H. Won Lee and Y.T. Im: Numerical modeling of dynamic recrystallization during nonisothermal hot compression by cellular automata and finite element analysis. Int. J. Mech. Sci. 52, 1277 (2010).

Y. Xu, L.X. Hu, and Y. Sun: Deformation behaviour and dynamic recrystallization of AZ61 magnesium alloy. J. Alloys Compd. 580, 262 (2013).

J.B. Li, Y. Liu, Y. Wang, B. Liu, and Y.H. He: Dynamic recrystallization behavior of an as-cast TiAl alloy during hot compression. Mater. Charact. 97, 169 (2014).

J.B. Jia, K.F. Zhang, and Z. Lu: Dynamic recrystallization kinetics of a powder metallurgy Ti–22Al–25Nb alloy during hot compression. Mater. Sci. Eng., A 607, 630 (2014).

H.L. Wei, G.Q. Liu, X. Xiao, and M.H. Zhang: Dynamic recrystallization behavior of a medium carbon vanadium microalloyed steel. Mater. Sci. Eng., A 573, 215 (2013).

L. Cheng, H. Chang, B. Tang, H.C. Kou, and J.S. Li: Deformation and dynamic recrystallization behavior of a high Nb containing TiAl alloy. J. Alloys Compd. 552, 363 (2013).

D.L. OuYang, M.W. Fu, and S.Q. Lu: Study on the dynamic recrystallization behavior of Ti-alloy Ti–10V–2Fe–3V in β processing via experiment and simulation. Mater. Sci. Eng., A 619, 26 (2014).

X.C. Li, L.L. Duan, J.W. Li, and X.C. Wu: Experimental study and numerical simulation of dynamic recrystallization behavior of a micro-alloyed plastic mold steel. Mater. Des. 66, 309 (2015).

ACKNOWLEDGMENTS

This work was supported by National Natural Science Foundation of China (Nos. 51305466, 51375502), National Key Basic Research Program (Grant No. 2013CB035801), State key laboratory of High Performance Complex Manufacturing (No. zzyjkt2014-01), the Project of Innovation-driven Plan in Central South University (Grant No. 2016CX008), the Natural Science Foundation for Distinguished Young Scholars of Hunan Province (Grant No. 2016JJ1017), and Program of Chang Jiang Scholars of Ministry of Education (Grant No. Q2015140), China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, MS., Li, KK., Lin, YC. et al. An improved kinetics model to describe dynamic recrystallization behavior under inconstant deformation conditions. Journal of Materials Research 31, 2994–3003 (2016). https://doi.org/10.1557/jmr.2016.325

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.325