Abstract

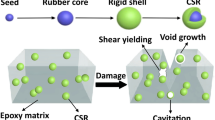

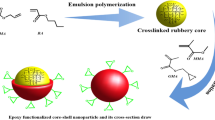

A novel core–shell particle that consists of epoxide-terminated hyperbranched polymer (HBP) and silica nanoparticles was incorporated into an epoxy/hydroxyl-terminated HBP blend to fabricate a high-performance epoxy thermoset. The effect of the core–shell particle content on the mechanical properties of the epoxy thermosets was investigated in detail. Results from tensile, flexural, and impact tests are provided. The impact fracture surface was studied by field emission-scanning electron microscopy. The incorporation of 2 wt% core–shell particles improved the tensile strength, percent elongation at break, flexural strength, and impact resistance of epoxy/hydroxyl-terminated HBP thermosets. Field emission-scanning electron micrographs showed that core–shell particle addition resulted in large-scale shear deformation and debonding from the epoxy matrix, and improved the epoxy resin toughness.

Similar content being viewed by others

References

A.A. Azeez, K.Y. Rhee, S.J. Park, and D. Hui: Epoxy clay nanocomposites—Processing, properties and applications: A review. Composites, Part B 45 (1), 308–320 (2013).

S. Zaioncz, A.A. Silva, A.S. Sirqueira, and B.G. Soares: Toughening of epoxy resin by methyl methacrylate/2-ethylhexyl acrylate copolymers: The effect of copolymer composition. Macromol. Mater. Eng. 292 (12), 1263–1270 (2007).

M. DeCarli, K. Kozielski, W. Tian, and R. Varley: Toughening of a carbon fibre reinforced epoxy anhydride composite using an epoxy terminated hyperbranched modifier. Compos. Sci. Technol. 65 (14), 2156–2166 (2005).

N. Domun, H. Hadavinia, T. Zhang, T. Sainsbury, G.H. Liaghat, and S. Vahid: Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 7 (23), 10294–10329 (2015).

S. Kar and A.K. Banthia: Synthesis and evaluation of liquid amine-terminated polybutadiene rubber and its role in epoxy toughening. J. Appl. Polym. Sci. 96 (6), 2446–2453 (2005).

L-C. Tang, X. Wang, Y-J. Wan, L-B. Wu, J-X. Jiang, and G-Q. Lai: Mechanical properties and fracture behaviors of epoxy composites with multi-scale rubber particles. Mater. Chem. Phys. 141 (1), 333–342 (2013).

P. Hazot, C. Pichot, and A. Maazouz: Synthesis of hairy acrylic core–shell particles as toughening agents for epoxy networks. Macromol. Chem. Phys. 201 (6), 632–641 (2000).

S. Sprenger, M.H. Kothmann, and V. Altstaedt: Carbon fiber-reinforced composites using an epoxy resin matrix modified with reactive liquid rubber and silica nanoparticles. Compos. Sci. Technol. 105, 86–95 (2014).

A. Dorigato, A. Pegoretti, and M. Quaresimin: Thermo-mechanical characterization of epoxy/clay nanocomposites as matrices for carbon/nanoclay/epoxy laminates. Mater. Sci. Eng., A 528 (19–20), 6324–6333 (2011).

M. Crespo, M. González, and J. Pozuelo: Magnetic silica:epoxy composites with a nano- and micro-scale control. Mater. Chem. Phys. 144 (3), 335–342 (2014).

A.J. Kinloch, K. Masania, A.C. Taylor, S. Sprenger, and D. Egan: The fracture of glass-fibre-reinforced epoxy composites using nanoparticle-modified matrices. J. Mater. Sci. 43 (3), 1151–1154 (2008).

D.J. Bray, P. Dittanet, F.J. Guild, A.J. Kinloch, K. Masania, R.A. Pearson, and A.C. Taylor: The modelling of the toughening of epoxy polymers via silica nanoparticles: The effects of volume fraction and particle size. Polymer 54 (26), 7022–7032 (2013).

B.R.K. Blackman, A.J. Kinloch, J.S. Lee, A.C. Taylor, R. Agarwal, G. Schueneman, and S. Sprenger: The fracture and fatigue behaviour of nano-modified epoxy polymers. J. Mater. Sci. 42 (16), 7049–7051 (2007).

S.O. Ilyin, T.V. Brantseva, I.Y. Gorbunova, S.V. Antonov, Y.M. Korolev, and M.L. Kerber: Epoxy reinforcement with silicate particles: Rheological and adhesive properties—Part I: Characterization of composites with natural and organically modified montmorillonites. Int. J. Adhes. Adhes. 61, 127–136 (2015).

A. Pan and L. He: Formation and properties of core–shell pentablock copolymer/silica hybrids. Mater. Chem. Phys. 147 (1–2), 5–10 (2014).

Z. Zeng, J. Yu, and Z-X. Guo: Preparation of epoxy-functionalized polystyrene/silica core–shell composite nanoparticles. J. Polym. Sci., Part A: Polym. Chem. 42 (9), 2253–2262 (2004).

A.J. Kinloch, R.D. Mohammed, A.C. Taylor, C. Eger, S. Sprenger, and D. Egan: The effect of silica nano particles and rubber particles on the toughness of multiphase thermosetting epoxy polymers. J. Mater. Sci. 40 (18), 5083–5086 (2005).

J. Gao, J. Li, S. Zhao, B.C. Benicewicz, H. Hillborg, and L.S. Schadler: Effect of graft density and molecular weight on mechanical properties of rubbery block copolymer grafted SiO2 nanoparticle toughened epoxy. Polymer 54 (15), 3961–3973 (2013).

S.P. Sharma and S.C. Lakkad: Impact behavior and fractographic study of carbon nanotubes grafted carbon fiber-reinforced epoxy matrix multi-scale hybrid composites. Composites, Part A 69, 124–131 (2015).

H. Im and J. Kim: Thermal conductivity of a graphene oxide-carbon nanotube hybrid/epoxy composite. Carbon 50 (15), 5429–5440 (2012).

T. Jiang, T. Kuila, N.H. Kim, B-C. Ku, and J.H. Lee: Enhanced mechanical properties of silanized silica nanoparticle attached graphene oxide/epoxy composites. Compos. Sci. Technol. 79, 115–125 (2013).

X. Jia, B. Liu, L. Huang, D. Hui, and X. Yang: Numerical analysis of synergistic reinforcing effect of silica nanoparticle–MWCNT hybrid on epoxy-based composites. Composites, Part B 54, 133–137 (2013).

W. Li, D. He, and J. Bai: The influence of nano/micro hybrid structure on the mechanical and self-sensing properties of carbon nanotube-microparticle reinforced epoxy matrix composite. Composites, Part A 54, 28–36 (2013).

T. Ahmad, R. Ahmad, M. Kamran, B. Wahjoedi, I. Shakoor, F. Hussain, F. Riaz, Z. Jamil, S. Isaac, and Q. Ashraf: Effect of Thal silica sand nanoparticles and glass fiber reinforcements on epoxy-based hybrid composite. Iran. Polym. J. 24 (1), 21–27 (2015).

D. Quan and A. Ivankovic: Effect of core–shell rubber (CSR) nano-particles on mechanical properties and fracture toughness of an epoxy polymer. Polymer 66, 16–28 (2015).

J. Chen, A.J. Kinloch, S. Sprenger, and A.C. Taylor: The mechanical properties and toughening mechanisms of an epoxy polymer modified with polysiloxane-based core–shell particles. Polymer 54 (16), 4276–4289 (2013).

M. Naguib, S. Grassini, and M. Sangermano: Core/shell PBA/PMMA–PGMA nanoparticles to enhance the impact resistance of UV-cured epoxy systems. Macromol. Mater. Eng. 298 (1), 106–112 (2013).

Y. Meng, X-H. Zhang, B-Y. Du, B-X. Zhou, X. Zhou, and G-R. Qi: Thermosets with core–shell nanodomain by incorporation of core crosslinked star polymer into epoxy resin. Polymer 52 (2), 391–399 (2011).

D. Quan and A. Ivankovic: Effect of core–shell rubber (CSR) nano-particles on mechanical properties and fracture toughness of an epoxy polymer. Polymer 66, 16–28 (2015).

Z. Su, B. Yu, X. Jiang, and J. Yin: Hybrid core–shell microspheres from coassembly of anthracene-containing POSS (POSS-AN) and anthracene-ended hyperbranched poly(ether amine) (hPEA-AN) and their responsive polymeric hollow microspheres. Macromolecules 46 (9), 3519–3528 (2013).

P. Yang, L.Y. Zhu, X. Xia, H.T. Wang, Q.G. Du, and W. Zhong: Toughening of epoxy resin with poly(methyl methacrylate) grafted silica core–shell particles. e-Polym. 11, 710–721 (2011).

S. Thakur and N. Karak: Ultratough, ductile, castor oil-based, hyperbranched, polyurethane nanocomposite using functionalized reduced graphene oxide. ACS Sustainable Chem. Eng. 2 (5), 1195–1202 (2014).

L. Pan, S. Lu, X. Xiao, Z. He, C. Zeng, J. Gao, and J. Yu: Enhanced mechanical and thermal properties of epoxy with hyperbranched polyester grafted perylene diimide. RSC Adv. 5 (5), 3177–3186 (2015).

A. Tomuta, F. Ferrando, À. Serra, and X. Ramis: New aromatic–aliphatic hyperbranched polyesters with vinylic end groups of different length as modifiers of epoxy/anhydride thermosets. React. Funct. Polym. 72 (9), 556–563 (2012).

S. Allauddin, M.K. Akhil Chandran, K.K. Jena, R. Narayan, and K.V.S.N. Raju: Synthesis and characterization of APTMS/melamine cured hyperbranched polyester-epoxy hybrid coatings. Prog. Org. Coat. 76 (10), 1402–1412 (2013).

S. Li, C. Cui, H. Hou, Q. Wu, and S. Zhang: The effect of hyperbranched polyester and zirconium slag nanoparticles on the impact resistance of epoxy resin thermosets. Composites, Part B 79, 342–350 (2015).

S. Li, C. Cui, and H. Hou: Synthesis of core–shell particles based on hyperbranced polyester and zirconium slag nanoparticles and its influence on the impact resistance of epoxy resin thermosets. Polym. Compos. (2015). doi: https://doi.org/10.1002/pc.23602.

S. Li, Q. Lin, H. Zhu, H. Hou, Y. Li, Q. Wu, and C. Cui: Improved mechanical properties of epoxy-based composites with hyperbranched polymer grafting glass-fiber. Polym. Adv. Technol. (2016). doi: https://doi.org/10.1002/pat.3746.

X. Huang, M.S. Heo, J-W. Yoo, J-S. Choi, and I. Kim: Hyperbranched aliphatic polyether esters by ring-opening polymerization of epoxidized 2-hydroxyethyl methacrylate. J. Polym. Sci., Part A: Polym. Chem. 52 (12), 1643–1651 (2014).

Y. Zhang, D. Zhang, C. Qin, and J. Xu: Physical and mechanical properties of dental nanocomposites composed of aliphatic epoxy resin and epoxidized aromatic hyperbranched polymers. Polym. Compos. 30 (2), 176–181 (2009).

J. Yu, X. Huang, C. Wu, X. Wu, G. Wang, and P. Jiang: Interfacial modification of boron nitride nanoplatelets for epoxy composites with improved thermal properties. Polymer 53 (2), 471–480 (2012).

L. Xie, X. Huang, Y. Huang, K. Yang, and P. Jiang: Core–shell structured hyperbranched aromatic polyamide/BaTiO3 hybrid filler for poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) nanocomposites with the dielectric constant comparable to that of percolative composites. ACS Appl. Mater. Interfaces 5 (5), 1747–1756 (2013).

R. Qian, J. Yu, L. Xie, Y. Li, and P. Jiang: Efficient thermal properties enhancement to hyperbranched aromatic polyamide grafted aluminum nitride in epoxy composites. Polym. Adv. Technol. 24 (3), 348–356 (2013).

S. Lv, Y. Yuan, and W. Shi: Strengthening and toughening effects of layered double hydroxide and hyperbranched polymer on epoxy resin. Prog. Org. Coat. 65 (4), 425–430 (2009).

R.P. Wang, T. Schuman, R.R. Vuppalapati, and K. Chandrashekhara: Fabrication of bio-based epoxy–clay nanocomposites. Green Chem. 16 (4), 1871–1882 (2014).

B. Qi, Q.X. Zhang, M. Bannister, and Y.W. Mai: Investigation of the mechanical properties of DGEBA-based epoxy resin with nanoclay additives. Compos. Struct. 75 (1–4), 514–519 (2006).

X. Wang, K. Xiao, L. Ye, Y-W. Mai, C.H. Wang, and L.R.F. Rose: Modelling mechanical properties of core–shell rubber-modified epoxies. Acta Mater. 48 (2), 579–586 (2000).

V.K. Srivastava: Modeling and mechanical performance of carbon nanotube/epoxy resin composites. Mater. Des. 39, 432–436 (2012).

J. Zhang and D. Jiang: Interconnected multi-walled carbon nanotubes reinforced polymer–matrix composites. Compos. Sci. Technol. 71 (4), 466–470 (2011).

W. Thitsartarn, X. Fan, Y. Sun, J.C.C. Yeo, D. Yuan, and C. He: Simultaneous enhancement of strength and toughness of epoxy using POSS–rubber core–shell nanoparticles. Compos. Sci. Technol. 118, 63–71 (2015).

G.G. Buonocore, L. Schiavo, I. Attianese, and A. Borriello: Hyperbranched polymers as modifiers of epoxy adhesives. Composites, Part B 53, 187–192 (2013).

ACKNOWLEDGMENTS

The authors gratefully acknowledge supports from the National Natural Science Foundation of China (51402251, 51578289, 51572234 and 51502259), the National Science and Technology Major Project of the Ministry of Science and Technology of China (2012ZX04010032), the joint research fund between Collaborative Innovation Center for Ecological Building Materials and Environmental Protection Equipments and Key Laboratory for Advanced Technology in Environmental Protection of Jiangsu Province (CP201506 and GX2015107), the project funded by the Flagship Major Development of Jiangsu Higher Education Institutions (PPZY2015A025), and the Natural science fund of Jiangsu Province (BK20130428).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, S., Lin, Q. & Cui, C. The effect of core–shell particles on the mechanical performance of epoxy resins modified with hyperbranched polymers. Journal of Materials Research 31, 1393–1402 (2016). https://doi.org/10.1557/jmr.2016.174

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.174