Abstract

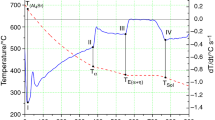

The tin–bismuth eutectic alloy possesses anomalous physicochemical properties that are dependent on temperature. This paper reports the interfacial reaction and growth behavior of the intermetallic compound (IMC) layer during the dissolution of solid copper in liquid eutectic tin–bismuth at 673–823 K under the influence of the structural transition of liquid eutectic tin–bismuth. The structural transition markedly affected the dissolution rate constant of solid copper and the growth rate of the IMCs. Correspondingly, the application of the liquid structural transition significantly decreased the activation energy of dissolution and increased the apparent activation energy for IMC growth. Moreover, two major roles of elemental Bi on the formation and growth of the IMCs were suggested.

Similar content being viewed by others

References

M.A.H. Howes and Z.P. Saperstein: Reaction of lead–tin solders with copper alloys. Weld. J. 48 (2), 80s (1969).

J.N. Glosli and F.H. Ree: Liquid–liquid phase transformation in carbon. Phys. Rev. Lett. 82, 4569 (1999).

Y. Katayama, T. Mizutani, W. Utsumi, O. Shimomura, M. Yamakata, and K. Funakoshi: A first-order liquid–liquid phase transition in phosphorus. Nature 403, 170 (2000).

P. McMillan: Phase transitions: Jumping between liquid states. Nature 403, 151 (2000).

X.F. Bian and W.M. Wang: Thermal-rate treatment and structure transformation of Al–13 wt% Si alloy melt. Mater. Lett. 44, 54 (2000).

Q.D. Qin, Y.G. Zhao, Y.H. Liang, and W. Zhou: Effects of melt superheating treatment on microstructure of Mg2Si/Al–Si–Cu composite. J. Alloys Compd. 399, 106 (2005).

C.L. Xu and Q.C. Jiang: Morphologies of primary silicon in hypereutectic Al–Si alloys with melt overheating temperature and cooling rate. Mater. Sci. Eng., A 437, 451 (2006).

F.Q. Zu, G.H. Ding, and X.F. Li: Change in solidification behavior of Bi–Sb10 alloy after liquid structural transition. J. Cryst. Growth 310, 397 (2008).

F.Q. Zu, J. Chen, X.F. Li, L.N. Mao, and Y.C. Liu: A new viewpoint to the mechanism for the effects of melt overheating on solidification of Pb–Bi alloys. J. Mater. Res. 24, 2378 (2009).

X. Qi, G.H. Ding, and G.W. Zhou: Dissolution of solid copper in liquid tin enhanced by the liquid structural transition. J. Appl. Phys. 115, 244907 (2014).

L. Wang, X.F. Bian, and J.T. Liu: Discontinuous structural phase transition of liquid metal and alloys (1). Phys. Lett. A 326, 429 (2004).

A.Q. Wu, L.J. Guo, C.S. Liu, E.G. Jia, and Z.G. Zhu: Internal friction behavior of liquid Bi–Sn alloys. Physica B 369, 51 (2005).

X.F. Li, F.Q. Zu, H.F. Ding, J. Yu, L.J. Liu, and Y. Xi: High-temperature liquid–liquid structure transition in liquid Sn–Bi alloys: Experimental evidence by electrical resistivity method. Phys. Lett. A 354 (4), 325 (2006).

J.F. Zhao, C. Unuvar, U. Anselmi-Tamburini, and Z.A. Munir: Kinetics of current-enhanced dissolution of nickel in liquid aluminum. Acta Mater. 55, 5592 (2007).

Y.W. Yen, W.T. Chou, Y. Tseng, C. Lee, and C.L. Hsu: Investigation of dissolution behavior of metallic substrates and intermetallic compound in molten lead-free solders. J. Electron. Mater. 37 (1), 73 (2008).

W.F. Feng, C.Q. Wang, and M. Morinaga: Electronic structure mechanism for the wettability of Sn-based solder alloys. J. Electron. Mater. 31 (3), 185 (2002).

X.W. Hu, Y.L. Li, and Z.X. Min: Interfacial reaction and IMC growth between Bi-containing Sn0.7Cu solders and Cu substrate during soldering and aging. J. Alloys Compd. 582, 341 (2014).

T.Y. Kang, Y.Y. Xiu, L. Hui, J.J. Wang, W.P. Tong, and C.Z. Liu: Effect of bismuth on intermetallic compound growth in lead free solder/Cu microelectronic interconnect. J. Mater. Sci. Technol. 27 (8), 741 (2011).

T.Y. Kang, Y.Y. Xiu, C.Z. Liu, L. Hui, J.J. Wang, and W.P. Tong: Bismuth segregation enhances intermetallic compound growth in SnBi/Cu microelectronic interconnect. J. Alloys Compd. 509, 1785 (2011).

H. Baker: ASM Handbook, Vol. 3: Alloy Phase Diagrams (ASM International, Metals Park, 1992).

Y. Takaku, X.J. Liu, I. Ohnuma, R. Kainuma, and K. Ishida: Interfacial reaction and Morphology between molten Sn base solders and Cu substrate. Mater. Trans. 45 (3), 646 (2004).

J. Chen, F.Q. Zu, X.F. Li, G.H. Ding, H.S. Chen, and L. Zou: Influence of a liquid structural change on the solidification of the alloy CuSn30. Met. Mater. Int. 14 (5), 569 (2008).

X.F. Li, F. Zhang, F.Q. Zu, X. Lv, Z.X. Zhao, and D.D. Yang: Effect of liquid–liquid structure transition on solidification and wettability of Sn–0.7Cu solder. J. Alloys Compd. 505, 472 (2010).

C.H.P. Lupis: Chemical Thermodynamics of Materials (Elsevier Science Publishing Co. Inc., Amsterdam, 1983); p. 116.

T. Itami, S. Munejiri, T. Masaki, H. Aoki, Y. Ishii, T. Kamiyama, Y. Senda, F. Shimojo, and K. Hoshino: Structure of liquid Sn over a wide temperature range from neutron scattering experiments and first-principles molecular dynamics simulation: A comparison to liquid Pb. Phys. Rev. B: Condens. Matter Mater. Phys. 67 (6), 064201 (2003).

C.S. Liu, G.X. Li, Y.F. Liang, and A.Q. Wu: Quantitative analysis based on the pair distribution function for understanding the anomalous liquid-structure change in In20Sn80. Phys. Rev. B: Condens. Matter Mater. Phys. 71, 064204 (2005).

O.M. Abdelhadi and L. Ladani: IMC growth of Sn–3.5Ag/Cu system: Combined chemical reaction and diffusion mechanisms. J. Alloys Compd. 537, 87 (2012).

S. Chada, W. Laub, R.A. Fournelle, and D. Shangguan: An improved numerical method for predicting intermetallic layer thickness developed during the formation of solder joints on Cu substrates. J. Electron. Mater. 28 (11), 1194 (1999).

D. Ma, W.D. Wang, and S.K. Lahiri: Scallop formation and dissolution of Cu–Sn intermetallic compound during solder reflow. J. Appl. Phys. 91 (5), 3312 (2002).

K.H. Prakash, and T. Sritharan: Interface reaction between copper and molten tin–lead solders. Acta Mater. 49, 2481 (2001).

V.I. Dybkov: Reaction Diffusion and Solid State Chemical Kinetics, 2nd ed. (Trans Tech Publications, Zurich, 2010).

ACKNOWLEDGMENTS

This work is financially supported by the National Natural Science Foundation of China (Grant Nos 51101067 and 51301073) and the Natural Science Foundation of the Higher Education Institutions of Anhui Province (Grant No. KJ2015A098).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, GH., Qi, X., Liu, SL. et al. Effect of liquid structural transition on the dissolution of solid copper in liquid eutectic tin–bismuth. Journal of Materials Research 31, 1145–1152 (2016). https://doi.org/10.1557/jmr.2016.118

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.118