Abstract

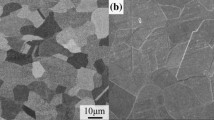

Five well-known Zr-based alloys of the systems Zr–Cu–Al–(Ni–Nb, Ni–Ti, Ag) (Cu = 15.4–36 at.%) with the highest glass-forming ability were comparatively analyzed regarding their pitting corrosion resistance and repassivation ability in a chloride-containing solution. Potentiodynamic polarization measurements were conducted in the neutral 0.01 M Na2SO4 + 0.1 M NaCl electrolyte and local corrosion damages were subsequently investigated with high resolution scanning electron microscopy (HR-SEM) coupled with energy dispersive x-ray spectroscopy (EDX). Both pitting and repassivation potential correlate with the Cu concentration, i.e., those potentials decrease with increasing Cu content. Pit morphology is not composition dependent: while initially hemispherical pits then develop an irregular shape and a porous rim. Corrosion products are rich in Cu, O, and often Cl species. A combination of low Cu and high Nb or Ti contents is most beneficial for a high pitting resistance of Zr-based bulk metallic glasses. The bulk glassy Zr57Cu15.4Al10Ni12.6Nb5 (Vit 106) and Zr52.5Cu17.9Al10Ni14.6Ti5 (Vit 105) alloys exhibit the highest pitting resistance.

Similar content being viewed by others

References

C. Suryanarayana and A. Inoue: Bulk Metallic Glasses (CRC Press, Boca Raton, 2011).

A. Gebert, K. Mummert, J. Eckert, and L. Schultz: Electrochemical investigations on the bulk glass forming Zr55Cu30Al10Ni5 alloy. Mater. Corros. 48, 293 (1997).

K. Mondal, B.S. Murty, and U.K. Chatterjee: Electrochemical behavior of multicomponent amorphous and nanocrystalline Zr-based alloys in different environments. Corros. Sci. 48, 2212 (2006).

U. Kamachi Mudali, S. Baunack, J. Eckert, L. Schultz, and A. Gebert: Pitting corrosion of bulk glass-forming zirconium-based alloys. J. Alloys Compd. 377, 290 (2004).

J.R. Scully, A. Gebert, and J. Payer: Corrosion and related mechanical properties of bulk metallic glasses. J. Mater. Res. 22, 302 (2007).

L. Huang, Y. Yokoyama, W. Wu, P.K. Liaw, S.J. Pang, A. Inoue, T. Zhang, and W. He: Ni-free Zr-Cu-Al-Nb-Pd bulk metallic glasses with different Zr/Cu ratios for biomedical applications. J. Biomed. Mater. Res. B. Appl. Biomater. 100B, 1472 (2012).

H.B. Lu, L.C. Zhang, A. Gebert, and L. Schultz: Pitting corrosion of Cu–Zr metallic glasses in hydrochloric acid solutions. J. Alloys Compd. 462, 60 (2008).

A. Gebert, U. Kamachi Mudali, J. Eckert, and L. Schultz: In Materials Research Society Symposium Proceedings (Materials Research Society, Warrendale, PA, 2004), p. 369–379.

B.A. Green, R.V. Steward, I. Kim, C.K. Choi, P.K. Liaw, K.D. Kihm, and Y. Yokoyama: In situ observation of pitting corrosion of the Zr50Cu40Al10 bulk metallic glass. Intermetallics 17, 568 (2009).

W.H. Peter, R.A. Buchanan, C.T. Liu, P.K. Liaw, M.L. Morrison, J.A. Horton, C.A.J. Carmichael, and J.L. Wright: Localized corrosion behavior of a zirconium-based bulk metallic glass relative to its crystalline state. Intermetallics 10, 1157 (2002).

M.L. Morrison, R.A. Buchanan, A. Peker, W.H. Peter, J.A. Horton, and P.K. Liaw: Cyclic-anodic-polarization studies of a Zr41.2Ti13.8Ni10Cu12.5Be22.5 bulk metallic glass. Intermetallics 12, 1177 (2004).

S.J. Pang, T. Zhang, H. Kimura, K. Asami, and A. Inoue: Corrosion behavior of Zr-(Nb-)Al-Ni-Cu glassy alloys. Mater. Trans. JIM 41, 1490 (2000).

S.J. Pang, T. Zhang, K. Asami, and A. Inoue: Formation, corrosion behavior, and mechanical properties of bulk glassy Zr–Al–Co–Nb alloys. J. Mater. Res. 18, 1652 (2003).

V.R. Raju, U. Kühn, U. Wolff, F. Schneider, J. Eckert, R. Reiche, and A. Gebert: Corrosion behaviour of Zr-based bulk glass-forming alloys containing Nb or Ti. Mater. Lett. 57, 173 (2002).

Y.H. Li, W. Zhang, C. Dong, J.B. Qiang, M. Fukuhara, A. Makino, and A. Inoue: Effects of Ni addition on the glass-forming ability, mechanical properties and corrosion resistance of Zr–Cu–Al bulk metallic glasses. Mater. Sci. Eng., A 528, 8551 (2011).

Z. Liu, L. Huang, W. Wu, X. Luo, M. Shi, P.K. Liaw, W. He, and T. Zhang: Novel low Cu content and Ni-free Zr-based bulk metallic glasses for biomedical applications. J. Non-Cryst. Solids 363, 1 (2013).

A. Gebert, K. Buchholz, A. Leonhard, K. Mummert, J. Eckert, and L. Schultz: Investigations on the electrochemical behaviour of Zr-based bulk metallic glasses. Mater. Sci. Eng., A 267, 294 (1999).

S. Baunack, U. Kamachi Mudali, and A. Gebert: Characterization of oxide layers on amorphous Zr-based alloys by Auger electron spectroscopy with sputter depth profiling. Appl. Surf. Sci. 252, 162 (2005).

B.A. Green, H.M. Meyer, R.S. Benson, Y. Yokoyama, P.K. Liaw, and C.T. Liu: A study of the corrosion behaviour of Zr50Cu(40−X)Al10PdX bulk metallic glasses with scanning Auger microanalysis. Corros. Sci. 50, 1825 (2008).

S. Hiromoto, A.P. Tsai, M. Sumita, and T. Hanawa: Effect of chloride ion on the anodic polarization behavior of the Zr65Al7.5Ni10Cu17.5 amorphous alloy in phosphate buffered solution. Corros. Sci. 42, 1651 (2000).

N. Homazava, A. Shkabko, D. Logvinovich, U. Krähenbühl, and A. Ulrich: Element-specific in situ corrosion behavior of Zr–Cu–Ni–Al–Nb bulk metallic glass in acidic media studied using a novel microcapillary flow injection inductively coupled plasma mass spectrometry technique. Intermetallics 16, 1066 (2008).

X.P. Nie, X.M. Xu, Q.K. Jiang, L.Y. Chen, Y. Xu, Y.Z. Fang, G.Q. Xie, M.F. Luo, F.M. Wu, X.D. Wang, Q.P. Cao, and J.Z. Jiang: Effect of microalloying of Nb on corrosion resistance and thermal stability of ZrCu-based bulk metallic glasses. J. Non-Cryst. Solids 355, 203 (2009).

L. Liu, C.L. Qiu, M. Sun, Q. Chen, K.C. Chan, and G.K.H. Pang: Improvements in the plasticity and biocompatibility of Zr–Cu–Ni–Al bulk metallic glass by the microalloying of Nb. Mater. Sci. Eng., A 449–451, 193 (2007).

K. Asami, H. Habazaki, A. Inoue, and K. Hashimoto: Recent development of highly corrosion resistant bulk glassy alloys. Mater. Sci. Forum 502, 225 (2005).

A. Gebert, P.F. Gostin, M. Uhlemann, J. Eckert, and L. Schultz: Interactions between mechanically generated defects and corrosion phenomena of Zr-based bulk metallic glasses. Acta Mater. 60, 2300 (2012).

H. Tanimoto, Y. Soga, Y. Takayanagi, and H. Mizubayashi: Dissolved-oxygen-induced intensive pitting corrosion of amorphous ZrCu alloys in thin NaCl solutions. Mater. Trans. 52, 1402 (2011).

A. Gebert, U. Kuehn, S. Baunack, N. Mattern, and L. Schultz: Pitting corrosion of zirconium-based bulk glass-matrix composites. Mater. Sci. Eng., A 415, 242 (2006).

V. Schroeder, C.J. Gilbert, and R.O. Ritchie: Comparison of the corrosion behaviour of a bulk amorphous metal, Zr41.2Ti13.8Cu12.5Ni10Be22.5, with its crystallized form. Scr. Mater. 38, 1481 (1998).

Z. Long, H. Wei, Y. Ding, P. Zhang, G. Xie, and A. Inoue: A new criterion for predicting the glass-forming ability of bulk metallic glasses. J. Alloys Compd. 475, 207 (2009).

J.J. Kruzic: Understanding the problem of fatigue in bulk metallic glasses. Metall. Mater. Trans. A 42, 1516 (2010).

A. Kawashima, Y. Yokoyama, and A. Inoue: Zr-based bulk glassy alloy with improved resistance to stress corrosion cracking in sodium chloride solutions. Corros. Sci. 52, 2950 (2010).

V. Schroeder, C.J. Gilbert, and R.O. Ritchie: Effect of aqueous environment on fatigue-crack propagation behavior in a Zr-based bulk amorphous metal. Scr. Mater. 40, 1057 (1999).

M.L. Morrison, R. Buchanan, P. Liaw, B.A. Green, G. Wang, C. Liu, and J.A. Horton: Corrosion–fatigue studies of the Zr-based Vitreloy 105 bulk metallic glass. Mater. Sci. Eng., A 467, 198 (2007).

A. Gebert, P.F. Gostin, and L. Schultz: Effect of surface finishing of a Zr-based bulk metallic glass on its corrosion behaviour. Corros. Sci. 52, 1711 (2010).

ASTM: Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution (ASTM International, West Conshohocken, PA 2000).

G.S. Frankel, J.R. Scully, and C. Jahnes: Repassivation of pits in aluminum thin films. J. Electrochem. Soc. 143, 1834 (1996).

B. Vishwanadh, G.J. Abraham, J.S. Neogy, R.S. Dutta, and G.K. Dey: Effect of structural defects, surface irregularities, and quenched-in defects on corrosion of Zr-based metallic glasses. Metall. Mater. Trans. A 40A, 1131 (2009).

Y.H. Kim and G.S. Frankel: Effect of noble element alloying on passivity and passivity breakdown of Ni. J. Electrochem. Soc. 154, C36 (2007).

G.S. Frankel: Pitting corrosion of metals. A review of the critical factors. J. Electrochem. Soc. 145, 2186 (1998).

J. Paillier, C. Mickel, P.F. Gostin, and A. Gebert: Characterization of corrosion phenomena of Zr–Ti–Cu–Al–Ni metallic glass by SEM and TEM. Mater. Charact. 61, 1000 (2010).

H. Bala and S. Szymura: Acid corrosion of amorphous and crystalline Cu-Zr alloys. Appl. Surf. Sci. 35, 41 (1988).

A. Kawashima, K. Ohmura, Y. Yokoyama, and A. Inoue: The corrosion behaviour of Zr-based bulk metallic glasses in 0.5M NaCl solution. Corros. Sci. 53, 2778 (2011).

B.A. Green: Localized corrosion behaviour of Zr-based bulk metallic glasses in neutral NaCl electrolytes. Doctoral Dissertation, The University of Tennessee, Knoxville, TN, 2008.

U. Köster and Triwikantoro: Oxidation of amorphous and nanocrystalline Zr-Cu-Ni-Al alloys. Mater. Sci. Forum 360–362, 29 (2001).

H-H. Strehblow: In Corrosion Mechanisms in Theory and Practice, P. Marcus ed.; Marcel Dekker, Inc.: New York, Basel, 2002; pp. 243–285.

N.J. Laycock and R.C. Newman: Localised dissolution kinetics, salt films and pitting potentials. Corros. Sci. 39, 1771 (1997).

N. Sato: The stability of localized corrosion. Corros. Sci. 37, 1947 (1995).

A. Tauseef, N.H. Tariq, J.I. Akhter, B.A. Hasan, and M. Mehmood: Corrosion behavior of Zr–Cu–Ni–Al bulk metallic glasses in chloride medium. J. Alloys Compd. 489, 596 (2010).

A. Gebert, F. Gostin, U. Kühn, and L. Schultz: Corrosion of a Zr-based bulk metallic glass with different surface finishing states. ECS Trans. 16, 1 (2009).

W.T. Thompson, M.H. Kaye, C.W. Bale, and A.D. Pelton: In Uhlig’s Corrosion Handbook, R.W. Revie ed. (John Wiley & Sons, Inc., New York, NY, 2000); pp. 125–136.

ACKNOWLEDGMENTS

G.S. Frankel is acknowledged for fruitful discussions and motivation for this study. The authors are grateful to D. Beitelschmidt for fruitful discussions, to M. Johne and F. Mayr for electrochemical tests, and to M. Frey and S. Donath for sample preparation. Funding from the German Research Foundation (DFG) under project Ge1106/11 in the Priority Program SPP-1594 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/jmr-editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Gostin, P.F., Eigel, D., Grell, D. et al. Comparing the pitting corrosion behavior of prominent Zr-based bulk metallic glasses. Journal of Materials Research 30, 233–241 (2015). https://doi.org/10.1557/jmr.2014.371

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.371