Abstract

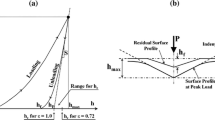

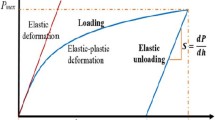

Differentiation of the energy-based power function used to represent the nanoindentation unloading response at the peak indentation load generally overestimates the contact stiffness. This is mainly because of the larger curvature associated with this function and the proximity between the contact and maximum penetration depths. Using the nanoindentation data from ceramics and metals, we have shown that these two errors can be eliminated if the derivative is multiplied by the geometric and stiffness correction factors, respectively. The stiffness correction factor is found to be a function of the elastic energy constant and is independent of the peak indentation load. The contact stiffness evaluated by the proposed method is in excellent agreement with that obtained from the power law derivative for a wide range of elastoplastic materials and peak indentation loads. The relationship between the elastic recovery ratio and elastic energy constant developed in this study further simplifies the proposed procedure.

Similar content being viewed by others

References

G.M. Pharr, W.C. Oliver, and F.R. Brotzen: On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 7, 613 (1992).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load- and displacement-sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

G.M. Pharr and A. Bolshakov: Understanding nanoindentation loading curves. J. Mater. Res. 17, 2660 (2002).

V. Marx and H. Balke: A critical investigation of the unloading behavior of sharp indentation. Acta Mater. 45, 3791 (1997).

T. Sawa and K. Tanaka: Simplified method for analyzing nanoindentation data and evaluating performance of nanoindentation instruments. J. Mater. Res. 16, 3084 (2001).

J. Gong, H. Miao, and Z. Peng: Analysis of the nanoindentation data measured with a Berkovich indenter for brittle materials: Effect of the residual contact stress. Acta Mater. 52, 785 (2004).

A.E. Giannakopoulos and S. Suresh: Determination of elastoplastic properties by instrumented sharp indentation. Scr. Mater. 40, 1191 (1999).

B.J. Briscoe and K.S. Sebastian: The elastoplastic response of poly(methyl methacrylate) to indentation. Proc. R. Soc. London, Ser. A 452, 439 (1996).

D. Tranchida and S. Piccarolo: On the use of the nanoindentation unloading curve to measure Young’s modulus of polymers on nanometer scale. Macromol. Rapid Commun. 26, 1800 (2005).

K.K. Jha, N. Suksawang, D. Lahiri, and A. Agarwal: Energy-based analysis of nanoindentation curves for cementitious materials. ACI Mater. J. 109, 81 (2012).

M.R. VanLandingham, J.S. Villarrubia, W.F. Guthrie, and G.F. Meyers: Nanoindentation of polymers: An overview. Macromol. Symp. 167, 15 (2001).

M. Sakai: Energy principle of the indentation-induced inelastic surface deformation and hardness of brittle materials. Acta Metall. Mater. 41, 1751 (1993).

M.T. Attaf: New ceramics related investigation of the indentation energy concept. Mater. Lett. 57, 4684 (2003).

J. Malzbender: Comment on the determination of mechanical properties from the energy dissipated during indentation. J. Mater. Res. 20, 1090 (2005).

M.T. Attaf: A unified aspect of power-law correlations for Berkovich hardness testing of ceramics. Mater. Lett. 57, 4627 (2003).

M.T. Attaf: Step by step building of a model for the Berkovich indentation cycle. Mater. Lett. 58, 507 (2004).

M.T. Attaf: New formulation of the nanomechanical quantities using the β-material concept and the indentation function. Mater. Lett. 58, 889 (2004).

S.V. Hainsworth, H.W. Chandler, and T.F. Page: Analysis of nanoindentation load-displacement loading curves. J. Mater. Res. 11, 1987 (1996).

Y.V. Milman: Plasticity characteristic obtained by indentation. J. Phys. D: Appl. Phys. 41, 074013 (2008).

K.K. Jha, N. Suksawang, and A. Agarwal: Analytical approach for the determination of nanomechanical properties for metals, in MEMS and Nanotechnology, Vol. 4, edited by T. Proulx (Conference proceedings of the Society for Experimental Mechanics, Uncasville, CT, 2011).

Z. Xiang, W. Fenghui, H. Jianye, and L. Tiejun: Determining the mechanical properties of solid oxide fuel cell by an improved work of indentation approach. J. Power Sources 201, 231 (2012).

H. Lee, S. Ko, J. Han, H. Park, and W. Hwang: Novel analysis for nanoindentation size effect using strain gradient plasticity. Scr. Mater. 53, 1135 (2005).

S.R. Bakshi, V. Singh, S. Seal, and A. Agarwal: Aluminum composite reinforced with multiwalled carbon nanotubes from plasma spraying of spray dried powders. Surf. Coat. Technol. 203, 1544 (2009).

S. Jayaraman, G.T. Hahn, W.C. Oliver, C.A. Rubin, and P.C. Bastias: Determination of monotonic stress-strain curve of hard materials from ultra-low-load indentation tests. Int. J. Solids Struct. 35, 365, (1998).

M.F. Doerner and W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1, 601 (1986).

S. Suresh and A.E. Giannakopoulos: A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755 (1998).

J.R. Tuck, A.M. Korsunsky, S.J. Bull, and R.I. Davidson: On the application of the work-of-indentation approach to depth-sensing indentation experiments in coated systems. Surf. Coat. Technol. 137, 217 (2001).

Acknowledgments

KKJ gratefully acknowledges the Dissertation Year Fellowship (DYF) from the University Graduate School, Florida International University. AA would like to acknowledge support from the National Science Foundation CAREER Award (NSF-DMI-0547178), the US Air Force Office of Scientific Research Grant (Grant No. FA9550-09-1-0297), and the DURIP Grant (N00014-06-0675) from the Office of Naval Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jha, K.K., Suksawang, N., Lahiri, D. et al. Evaluating initial unloading stiffness from elastic work-of-indentation measured in a nanoindentation experiment. Journal of Materials Research 28, 789–797 (2013). https://doi.org/10.1557/jmr.2013.3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.3