Abstract

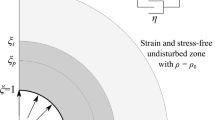

A new expanding cavity model (ECM) for describing conical indentation of elastic-ideally plastic material is developed. For the proposed ECM, it is assumed that the volume of material displaced by the indenter is equal to the volume loss, due to elastic deformation, in the material and depends on the pile-up or sink-in. It was shown that the proposed ECM matches very well numerical data in the final portion of the transition regime for which the contact pressure lies between approximately 2.5Y and 3Y. For material of large E/Y ratio, the new ECM also provides results which are very close to the numerical data in the plastic-similarity regime (regime in which Cf = 3). For material of smaller E/Y ratio, the proposed ECM gives better results than the Johnson’s ECM because pile-up or sink-in is taken into account.

Similar content being viewed by others

References

A.E.H. Love: Boussinesq’s problem for a rigid cone. Q. J. Math. 10, 161 (1939).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, England, 1985), pp. 171.

D. Tabor: The Hardness of Metals (Clarendon Press, Oxford, England, 1951), pp. 101.

M. Mata and J. Alcala: Mechanical property evaluation through sharp indentations in elastoplastic and fully plastic contact regimes. J. Mater. Res. 18, 1705 (2003).

D.M. Marsh: Plastic flow in glass. Proc. R. Soc. London, Ser. A 279, 420 (1964).

X-L. Gao: New expanding cavity model for indentation hardness including strain-hardening and indentation size effects. J. Mater. Res. 21, 1317 (2006).

M. Mata, O. Casals, and J. Alcala: The plastic zone size in indentation experiments: The analogy with the expansion of a spherical cavity. Int. J. Solids Struct. 43, 5994 (2006).

K.L. Johnson: The correlation of indentation experiments. J. Mech. Phys. Solids 18, 115 (1970).

R. Hill: The Mathematical Theory of Plasticity (Oxford University Press, London, England, 1950).

C.J. Studman, M.A. Moore, and S.E. Jones: On the correlation of indentation experiments. J. Phys. D: Appl. Phys. 10, 949 (1977).

S.S. Chiang, D.B. Marshall, and A.G. Evans: The response of solids to elastic/plastic indentation. I. Stresses and residual stresses. J. Appl. Phys. 53, 298 (1982).

G. Feng, S. Qu, Y. Huang, and W.D. Nix: An analytical expression for the stress field around an elastoplastic indentation/contact. Acta Mater. 55, 2929 (2007).

E.H. Yoffe: Elastic stress fields caused by indenting brittle materials. Philos. Mag. A 46, 617 (1982).

A.C. Fischer-Cripps: Elastic–plastic behaviour in materials loaded with a spherical indenter. J. Mater. Sci. 32, 727 (1997).

D. Kramer, H. Huang, M. Kriese, J. Robach, J. Nelson, A. Wright, D. Bahr, and W.W. Gerberich: Yield strength predictions from the plastic zone around nanocontacts. Acta Mater. 47, 333 (1999).

X. Hernot and F. Pichot: Influence du coefficient de Poisson sur les régimes d’indentation sphérique. Mat. Tech. 96, 31 (2009).

O. Bartier and X. Hernot: Etude des régimes de déformation de matériaux élastiques parfaitement plastiques au cours de l’indentation parabolique et sphérique. Mat. Tech. 96, 20 (2009).

J. Alcala, A.C. Barone, and M. Anglada: The influence of plastic hardening on surface deformation modes around Vickers and spherical indents. Acta Mater. 48, 3451 (2000).

E. Felder: Analytical correlation of indentation experiments. Philos. Mag. 86, 5239 (2006).

S. Malherbe, S. Benayoun, S. Morel, and A. Iost: Caractérisation mécanique de matériaux élastoplastiques—utilisation d’indenteurs axisymétriques. Mater. Tech. 93, 213 (2005).

H. Pelletier: Étude de la formation du bourrelet autour des empreintes de nanoindentation. Mater. Tech. 93, 229 (2005).

W. Zielinski, H. Huang, and W.W. Gerberich: Microscopy and microindentation mechanics of single crystal Fe-3 wt. % Si: Part II. TEM of the indentation plastic zone. J. Mater. Res. 8, 1300 (1993).

M. Mata and J. Alcala: The role of friction on sharp indentation. J. Mech. Phys. Solids 52, 145 (2004).

X-L. Gao: An expanding cavity model incorporating strain-hardening and indentation size effects. Int. J. Solids Struct. 43, 6615 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hernot, X., Bartier, O. An expanding cavity model incorporating pile-up and sink-in effects. Journal of Materials Research 27, 132–140 (2012). https://doi.org/10.1557/jmr.2011.394

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.394