Abstract

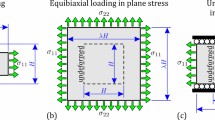

Geometrical self-similarity is a feature of mathematically sharp indenters such as conical and Berkovich indenters. However, self-similarity is considered inappropriate for practical use because of inevitable indenter tip blunting. In this study, we analyze the load–depth curves of conical indenters with various tip radii via finite element analyses. Based on the numerical data, we propose a method of restoring the Kick’s law coefficient C of finite tip-radius indenter to that of zero tip-radius indenter, thereby retaining the self-similarity of the sharp indenter. We then regress the unloading slope for the evaluation of elastic modulus in several ways. Finally, we establish a method to evaluate elastic modulus, which successfully provides the value of the elastic modulus with a maximum error of less than 5%, regardless of tip radius and material properties of both indenter and specimen.

Similar content being viewed by others

References

I.N. Sneddon: The relaxation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 1965

M.F. Doerner W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1, 601 1986

W.C. Oliver G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 1992

J.S. Field M.V. Swain: Determining the mechanical properties of small volumes of material from submicrometer spherical indentations. J. Mater. Res. 10, 101 1995

A.E. Giannakopoulos S. Suresh: Determination of elastoplastic properties by instrumented sharp indentation. Scr. Mater. 40, 1191 1999

N. Chollacoop, M. Dao S. Suresh: Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713 2003

J.L. Bucaille, S. Stauss, P. Schwaller J. Michler: A new technique to determine the elastoplastic properties of thin metallic films using sharp indenters. Thin Solid Films 447–448, 239 2004

H. Lee, J.H. Lee G.M. Pharr: A numerical approach to spherical indentation techniques for material property evaluation. J. Mech. Phys. Solids 53, 2037 2005

M. Beghini, L. Bertini, and V. Fontanari: Evaluation of the stress–strain curve of metallic materials by spherical indentation. Int. J. Solids Struct. 43, 2441 2006

X. Chen, N. Ogasawara, M. Zhao N. Chiba: On the uniqueness of measuring elastoplastic properties from indentation: The indistinguishable mystical materials. J. Mech. Phys. Solids 55, 1618 2007

S. Suresh A.E. Giannakopoulos: A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 46, 5755 1998

Y.H. Lee D. Kwon: Estimation of biaxial surface stress by instrumented indentation with sharp indenters. Acta Mater. 52, 1555 2004

Z.H. Xu X. Li: Influence of equi-biaxial residual stress on unloading behaviour of nanoindentation. Acta Mater. 53, 1913 2005

J.H. Lee H. Lee: An indentation method based on FEA for equi-biaxial residual stress evaluation. Trans. KSME 30, 42 2006

A.F. Bower, N.A. Fleck, A. Needleman N. Ogbonna: Indentation of a power law creeping solid. Proc. R. Soc. London Ser. A 441, 97 1993

J.A. LaManna: A study of the relationship between indentation creep and uniaxial creep. Ph.D. Dissertation, University of Tennessee, TN, 2006

B.R. Lawn, A.G. Evans D.B. Marshall: Elastic/plastic indentation damage in ceramics: The median/radial crack system. J. Am. Ceram. Soc. 63, 574 1980

G.M. Pharr: Measurement of mechanical properties by ultra-low-load indentation. Mater. Sci. Eng., A 253, 151 1998

J. Menčík M.V. Swain: Error associated with depth-sensing microindentation tests. J. Mater. Res. 10, 1491 1995

Y-T. Cheng C-M. Cheng: Further analysis of indentation loading curves: Effects of tip rounding on mechanical property measurements. J. Mater. Res. 13, 1059 1998

K. Herrmann, N.M. Jennett, W. Wegener, J. Meneve, K. Hasche R. Seemann: Progress in determination of the area function of indenters used for nanoindentation. Thin Solid Films 377–378, 394 2000

Z. Xue, Y. Huang, K.C. Hwang M. Li: The influence of indenter tip radius on the micro-indentation hardness. J. Eng. Mater. Technol. 124, 371 2002

M. Troyon L. Huang: Correction factor for contact area in nanoindentation measurements. J. Mater. Res. 20, 610 2005

ABAQUS User’s Manual, Version 6.5 Hibbitt, Karlsson and Sorensen, Inc. Pawtucket RI, 2004

G.M. Pharr, W.C. Oliver F.R. Brotzen: On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 7, 613 1992

C-M. Cheng Y-T. Cheng: On the initial unloading slope in indentation of elastic-plastic solids by an indenter with an axisymmetric smooth profile. Appl. Phys. Lett. 71, 2623 1997

A.C. Fischer-Cripps: Critical review of analysis and interpretation of nanoindentation test data. Surf. Coat. Technol. 200, 4153 2006

ISO 14577, Metallic materials-instrumented indentation test for hardness and materials parameters, ISO Central Secreariat, 1 rue de Varembé, 1211 Geneva, 20 Switzerland

J.R. Rice G.F. Rosengren: Plane strain deformation near a crack-tip in a power law hardening material. J. Mech. Phys. Solids 16, 1 1968

S. Shim, W.C. Oliver G.M. Pharr: A comparison of 3D finite element simulations for Berkovich and conical indentation of fused silica. Int. J. Surf. Sci. Eng. 1, 259 2007

Z-H. Xu X. Li: Effects of indenter geometry and material properties on the correction factor of Sneddon’s relationship for nanoindentation of elastic and elastic-plastic materials. Acta Mater. 56, 1399 2008

J.H. Lee: A numerical approach and experimental verification of the indentation techniques for material property and residual stress evaluation. Ph.D. Dissertation, Sogang University, Seoul, Korea, 2006

M. Dao, N. Chollacoop, J.V. Vliet, T.A. Venkatesh S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 2001

Acknowledgment

H. Lee is grateful for the support provided by a grant from the Korea Science and Engineering Foundation (Grant No. KOSEF R01-2007-000-10942-0).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.H., Lee, H. & Kim, D.H. A numerical approach to evaluation of elastic modulus using conical indenter with finite tip radius. Journal of Materials Research 23, 2528–2537 (2008). https://doi.org/10.1557/jmr.2008.0314

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2008.0314