Abstract

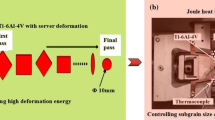

Instead of conventional grain-refinement treatments for improving the ductility of fully lamellar TiAl alloys, multiorientational, lamellar, subcolony refinement with good ductility has been achieved simply by using an electric-current pulse treatment. The microstructural refinement mechanism is attributed to the transformation on heating of γ laths in the prior large-grain lamellar structure to Widmanstätten α in several orientations, which on subsequent cooling forms lamellar structure colonies in multiple orientations. This kind of refined multiple-colony lamellar structure was found to enhance the ductility of the TiAl alloy.

Similar content being viewed by others

References

Y.W. Kim: Microstructural evolution and mechanical-properties of a forged gamma-titanium aluminide alloy. Acta Metall. Mater. 40, 1121 1992

S.G. Pyo N.J. Kim: Role of interface boundaries in the deformation behavior of TiAl polysynthetically twinned crystal: In situ transmission electron microscopy deformation study. J. Mater. Res. 20, 1888 2005

J.X. Zhang H.Q. Ye: The deformation twin in lamellar Ti3Al/TiAl structure. Solid State Commun. 126, 217 2003

H.L. Zhu, D.Y. Seo, K. Maruyama P. Au: Grain boundary morphology and its effect on creep of TiAl alloys. Mater. Trans. 45, 3343 2004

W. Schillinger, H. Clemens, G. Dehm A. Bartels: Microstructural stability and creep behavior of a lamellar gamma-TiAl based alloy with extremely fine lamellar spacing. Intermetallics 10, 459 2002

J. Beddoes, W. Wallace L. Zhao: Current understanding of creep behaviour of near gamma-titanium aluminides. Int. Mater. Rev. 40, 197 1995

K. Maruyama, N. Yamada H. Sato: Effects of lamellar spacing on mechanical properties of fully lamellar Ti-39.4mol%Al alloy. Mater. Sci. Eng., A 319(321), 360 2001

S.A. Jones M.J. Kaufman: Phase-equilibria and transformations in intermediate titanium aluminum-alloys. Acta Metall. Mater. 41, 387 1993

A. Denquin S. Naka: Phase transformation mechanisms involved in two-phase TiAl-based alloys: 1. Lamellar structure formation. Acta Mater. 44, 343 1996

X.D. Zhang, S. Godfrey, M. Weaver, M. Strangwood, P. Threadgill, M.J. Kaufman M.H. Loretto: The massive transformation in Ti-Al alloys: Mechanistic observations. Acta Mater. 44, 3723 1996

D. Veeraraghavan, P. Wang V.K. Vasudevan: Kinetics and thermodynamics of the α → γm, massive transformation in a Ti-47.5 at.%Al alloy. Acta Mater. 47, 3313 1999

W. Ping, G.B. Viswanathan V.K. Vasudevan: Observation of a massive transformation from alpha to gamma in quenched Ti-48 at.%Al-alloys. Metall. Trans. 23, 690 1992

W.J. Zhang, L. Francesconi, E. Evangelista G.L. Chen: Characterization of Widmanstätten laths and interlocking boundaries in fully-lamellar TiAl-base alloy. Scripta Mater. 37, 627 1997

C.T. Liu, J.H. Schneibel, P.J. Maziasz, J.L. Wright D.S. Easton: Tensile properties and fracture toughness of TiAl alloys with controlled microstructures. Intermetallics 4, 429 1996

S.L. Semiatin, V. Seetharaman, D.M. Dimiduk K.K.G. Ashbee: Phase transformation behavior of gamma titanium aluminide alloys during supertransus heat treatment. Metall. Mater. Trans. A 29, 7 1998

D.M. Dimiduk, P.L. Martin Y.W. Kim: Microstructure development in gamma alloy mill products by thermomechanical processing. Mater. Sci. Eng., A 243, 66 1998

D. Hu, A.J. Huang X. Wu: TEM characterization of Widmanstätten microstructures in TiAl-based alloys. Intermetallics 13, 211 2005

K. Nakai Y. Ohmri: Decomposition of α-phase into massive and Widmanstätten structures in a Ti-48 at.% Al alloy in Proceedings of the International Conference on Solid-Solid Phase Transformations’99 (JIMIC-3) edited by M. Koiwa, K. Otsuka, and T. Miyazaki JIM Tokyo 1999 153

S.R. Dey, A. Hazotte, E. Bouzy S. Naka: Development of Widmanstätten laths in a near-gamma TiAl alloy. Acta Mater. 53, 3783 2005

M.J. Blackburn: Some aspects of phase transformations in titanium alloys in The Science Technology and Application of Titanium edited by R.I. Jaffee and N.E. Promisel Pergamon Press Oxford 1970 633

A. Calka D. Wexler: Mechanical milling assisted by electrical discharge. Nature 419, 147 2002

W. Zhang, W.S. Zhao, D.X. Li M.L. Sui: Martensitic transformation from alpha-Ti to beta-Ti on rapid heating. Appl. Phys. Lett. 84, 4872 2004

H. Conrad A.F. Sprecher: Basic problems and applications in Dislocations in Solids edited by F.R.N. Nabarro Elsevier Amsterdam, The Netherlands 1989 499

Y.G. Zhang, Y.F. Han, G.L. Chen, J.T. Guo, X.J. Wan D. Feng: Structural Intermetallics National Defence Industry Press Bejing 2001 485 705

D. Veeraraghavan, U. Pilchowski, B. Natarajan V.K. Vasudevan: Phase equilibria and transformations in Ti-(25-52) at.% Al alloys studied by electrical resistivity measurements. Acta Mater. 46, 405 1998

H.L. Zhu, K. Maruyama J. Matsuda: Microstructural refinement mechanism by controlling heating process in multiphase materials with particular reference to γ-TiAl. Appl. Phys. Lett. 88, 131908 2006

H. Clemens, A. Bartels, S. Bystrzanowski, H. Chladil, H. Leitner, G. Dehm, R. Gerling F.P. Schimansky: Grain refinement in γ-TiAl-based alloys by solid-state phase transformations. Intermetallics 14, 1380 2006

M. Perez-Bravo, I. Madariaga, K. Ostolaza M. Tello: Microstructural refinement of a TiAl alloy by a two step heat treatment. Scripta Mater. 53, 1141 2005

Q.F. Xia, J.N. Wang, Y. Wang J. Yang: Effect of heating rate on the grain refinement of a TiAl alloy by cyclic heat treatment. Mater. Sci. Eng., A 300, 309 2000

R.V. Ramanujan: The transformation between the gamma-phase and alpha-phase in binary and ternary gamma-based titanium aluminides. Acta Metall. Mater. 42, 2313 1994

H.Y. Yasuda, T. Nakano Y. Umakoshi: Cyclic deformation-behavior of TiAl alloys containing oriented lamellae. Philos. Mag. A 71, 127 1995

K. Kishida, H. Iuni M. Yamaguchi: Deformation of lamellar structure in TiAl-Ti3Al two-phase alloys. Philos. Mag. A 78, 1 1998

Acknowledgments

This research was supported by the National Nature Science Foundation of China, Grant No. 50571100, the Hundred Talents Project funded by the Chinese Academy of Sciences, and the Special Funds for the Major State Basic Research Project of China (No. 2002CB613503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, J., Sui, M., Cui, Y. et al. Ductile TiAl alloy with a Widmanstätten lamellar structure formed by rapid heating. Journal of Materials Research 23, 949–953 (2008). https://doi.org/10.1557/jmr.2008.0138

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2008.0138